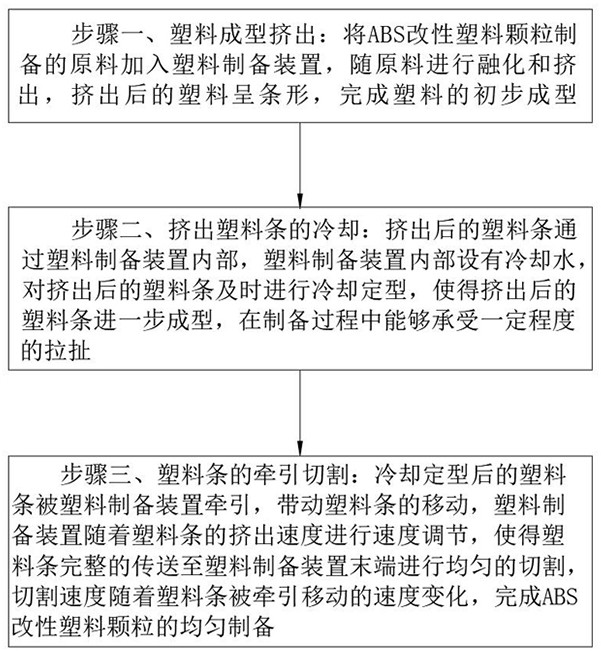

Preparation process of ABS (Acrylonitrile Butadiene Styrene) modified plastic particles

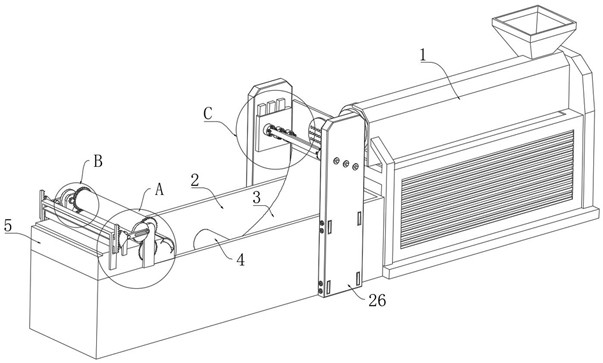

A technology of plastic granules and preparation process, which is applied in the field of preparation of ABS modified plastic granules, can solve the problems that the extrusion speed of plastic strips is difficult to be completely uniform, the size of plastic granules is not uniform, the plastic strips are pulled and deformed, and the like, so as to achieve uniform cutting. , Uniform plastic particles, avoid the effect of pulling and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

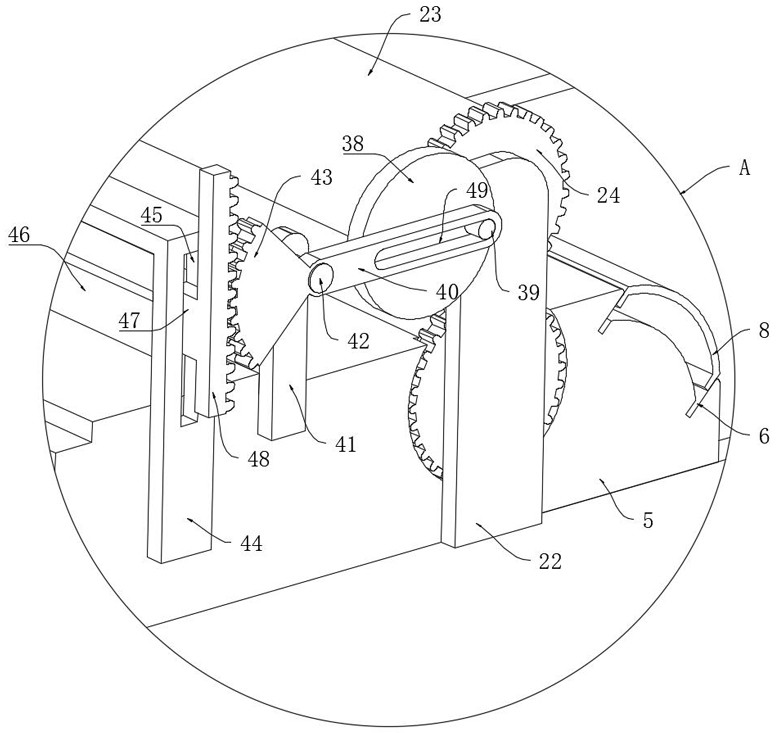

[0042] As an embodiment of the present invention, the variable speed traction device includes a lifting groove 6, a second spring 19, a first mounting bracket 14 and two second mounting brackets 22, and the lifting groove 6 is opened on the cutting table 5 towards the plastic extruder 1. One end of the lifting groove 6 is fixed with a plurality of first springs 7 in the inner array, and the end of all the first springs 7 facing away from the lifting groove 6 is jointly fixed with an arc-shaped lifting plate 8, and two second mounting brackets 22 are symmetrically fixed on the cutting edge. On both sides of the table 5, two second rotating rollers 23 located on the same vertical plane are jointly rotated and connected between the two second mounting frames 22, and first gears 24 are fixed at both ends of the two second rotating rollers 23. , the adjacent first gears 24 mesh with each other, the side of the lower first gear 24 facing away from the second rotating roller 23 is coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com