Manufacturing method of TEOS film

A manufacturing method and thin-film technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problem of easy delamination of TEOS film, and achieve lower leakage current, better adhesion, and improved compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased from the market.

[0027] The characteristics and performance of the present application will be described in further detail below in conjunction with the examples.

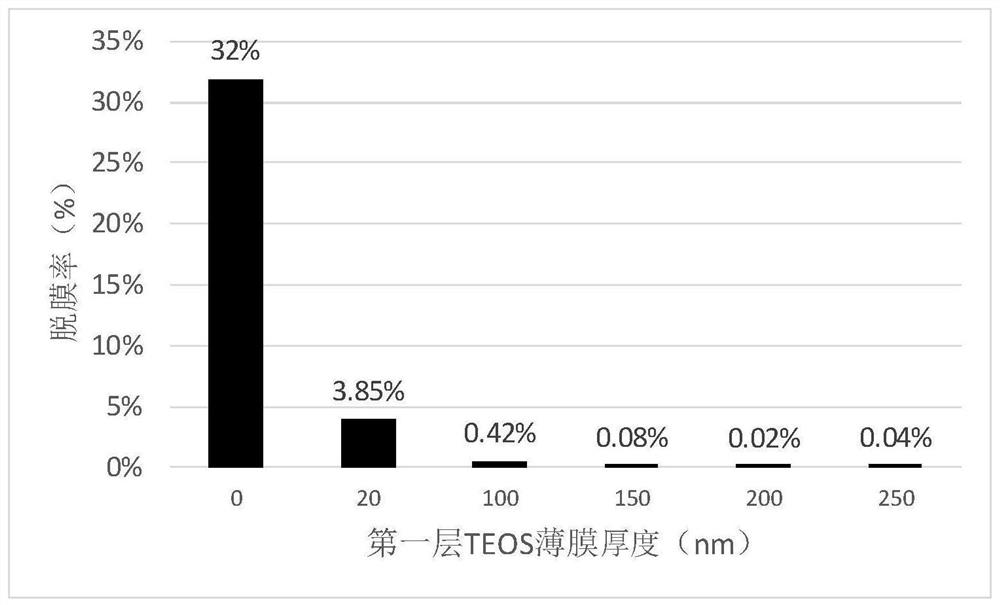

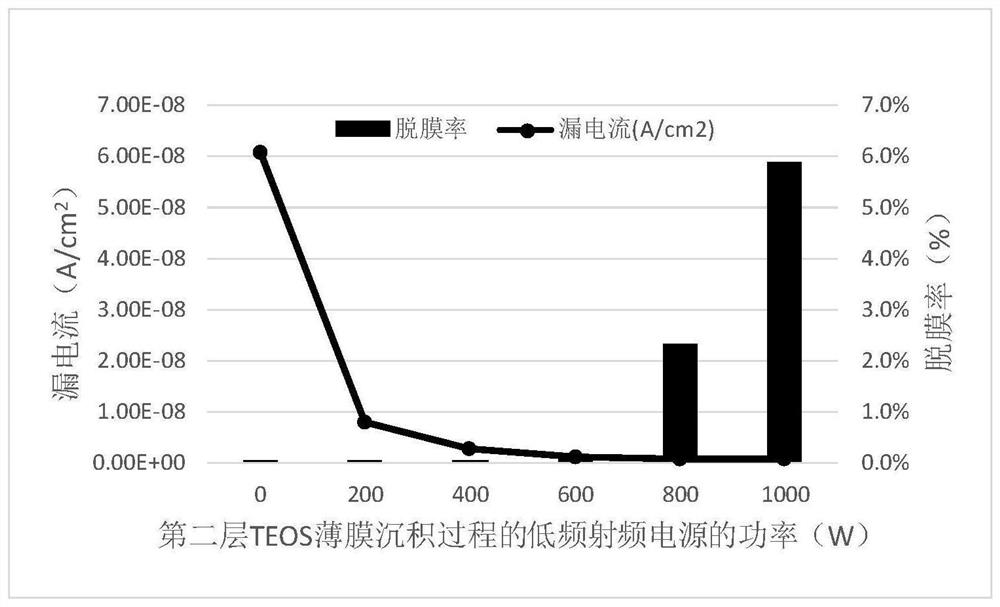

[0028] In the field of semiconductors, related technologies use chemical vapor deposition to produce TEOS films. In order to promote the reaction and improve the insulation performance of TEOS films, low-frequency radio frequency power is used to ionize the raw material...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap