V-SPC stone-plastic wood floor and preparation method thereof

A wood floor, stone plastic technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of easy release of harmful substances formaldehyde, high production costs, waterproof, moisture-proof, fireproof, and insect-proof performance. The effect of good borer performance, saving wood and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

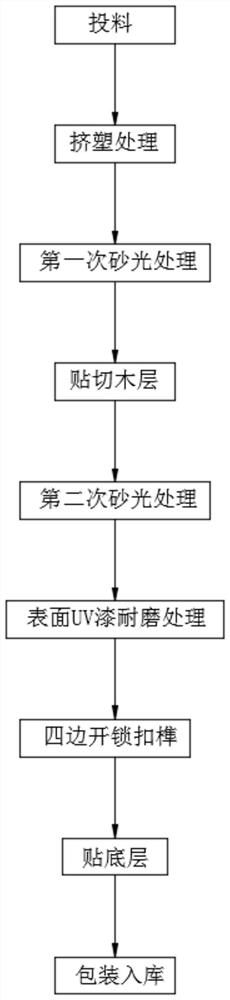

[0029] Further, a preparation method of V-SPC stone-plastic wood flooring comprises the following steps:

[0030] S1. Put stone powder, plastic granules, additives, plant fibers, coupling agent, and crosslinking agent into the mixer, and mix them uniformly;

[0031] S2. Carry out an extrusion operation through an extruder, extrude and form a stone-plastic plate, and perform the first sanding treatment after aging for 24 hours to obtain a base material layer 1;

[0032] S3, using a polyurethane adhesive to paste the decorative layer 2 on the front of the substrate layer 1, and paste the balance layer 3 on the back of the substrate layer 1, and press and paste it for 24 hours by a multi-layer press;

[0033] S4. Carry out the second sanding treatment again, and carry out the surface UV paint wear-resistant treatment on the upper end of the decorative layer 2 to obtain the wear-resistant layer 4;

[0034] S5. Unlock the tenons on the four sides of the base material layer 1, stic...

Embodiment 2

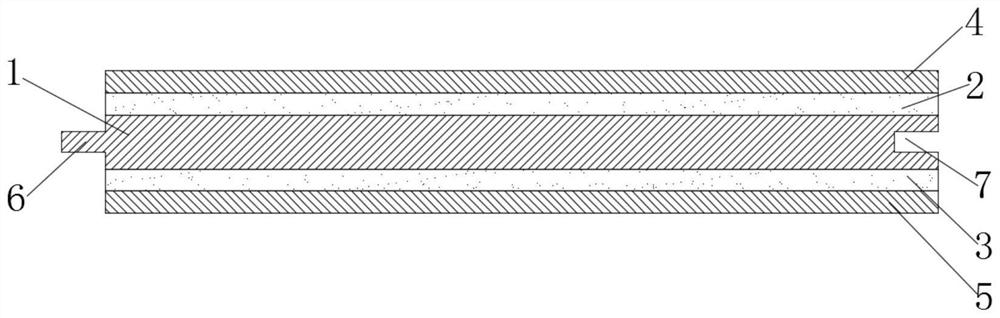

[0041] In Example 2, a V-SPC stone-plastic wood flooring includes a base material layer 1, the upper end of the base material layer 1 is glued with a decorative layer 2, and the lower end of the base material layer 1 is glued with a balance layer 3 , the upper end of the decorative layer 2 is provided with a wear-resistant layer 4, the lower end of the balance layer 3 is glued with a bottom layer 5, and the side wall of the base material layer 1 is also provided with a tenon 6 and a tenon groove 7 corresponding to each other, The tenon 6 and the tenon groove 7 are matched.

[0042] Further, the substrate layer 1 is an SPC stone-plastic plate, and the thickness of the substrate layer 1 is 10mm; the decorative layer 2 is a sliced wood layer or a rotary-cut wood layer, and the thickness of the decorative layer 2 is 2mm; the balance layer 3 is a rotary cut wood layer, the thickness of the balance layer 3 is 1.5mm, and the bottom layer 5 is a cork pad or an IXPE buffer pad.

[0...

Embodiment 3

[0056]In Example 3, a V-SPC stone-plastic wood flooring includes a base material layer 1, the upper end of the base material layer 1 is glued with a decorative layer 2, and the lower end of the base material layer 1 is glued with a balance layer 3 , the upper end of the decorative layer 2 is provided with a wear-resistant layer 4, the lower end of the balance layer 3 is glued with a bottom layer 5, and the side wall of the base material layer 1 is also provided with a tenon 6 and a tenon groove 7 corresponding to each other, The tenon 6 and the tenon groove 7 are matched.

[0057] Further, the substrate layer 1 is an SPC stone-plastic plate, and the thickness of the substrate layer 1 is 8mm; the decorative layer 2 is a sliced wood layer or a rotary-cut wood layer, and the thickness of the decorative layer 2 is 0.5mm; the balance The layer 3 is a rotary cut wood layer, the thickness of the balance layer 3 is 0.5mm, and the bottom layer 5 is a cork pad or an IXPE buffer pad. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com