Method and system for decontaminating retrograde condensation zone of target well

A target well, condensate technology, applied in liquid/gas jet drilling, directional drilling, earthwork drilling and production, etc., can solve the problems of difficult gas communication, discount of anti-condensation removal effect, short validity period of anti-condensation removal, etc. Achieve the effect of decontamination and long validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

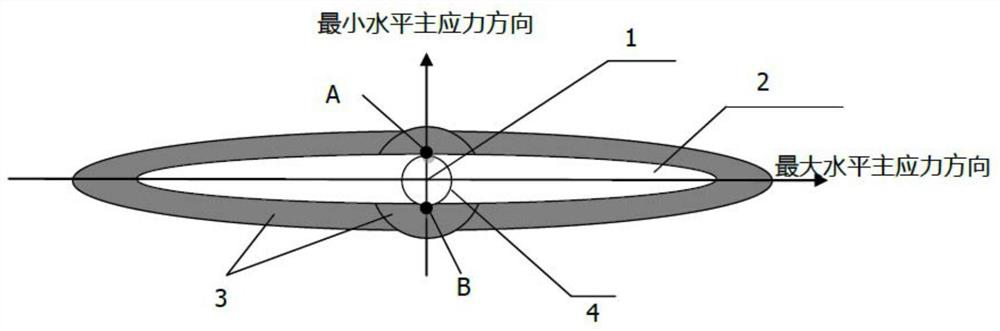

[0026] Before introducing specific embodiments of the present invention, a brief introduction will be made to the anti-condensation area of the target well. like figure 1 As shown, an anti-condensation zone 3 is formed around the wellbore 1 (or casing 4) and the original artificial fracture 2 of the target well. Wherein, the original artificial fracture 2 is located on the outside of the casing 4 around the wellbore 1. Viewed along the direction of the minimum horizontal principal stress, the edge of the original artificial fracture 2 may just be located at the outer wall of the casing 4, or may be at a distance from The outer wall of the casing 4 has a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com