Pipeline leakage monitoring method based on fiber bragg grating temperature measurement technology

A fiber grating and technology technology, which is applied in the field of pipeline leakage monitoring based on fiber grating temperature measurement technology, can solve the problems of surrounding temperature sensing leakage points, leakage points difficult to pipeline vibration, and inability to perceive through vibration, etc., and the cost is achieved. Low, high sensitivity, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

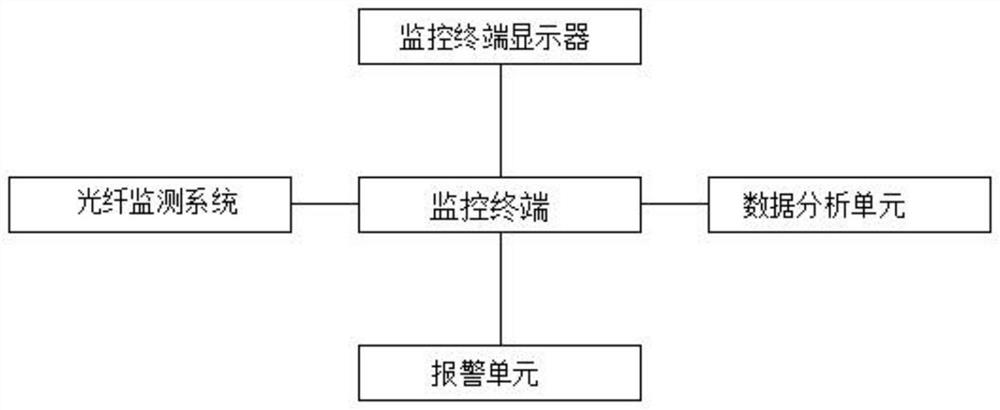

[0029] see Figure 1~2 , in an embodiment of the present invention, a pipeline leakage monitoring method based on fiber Bragg grating temperature measurement technology, comprising the following steps:

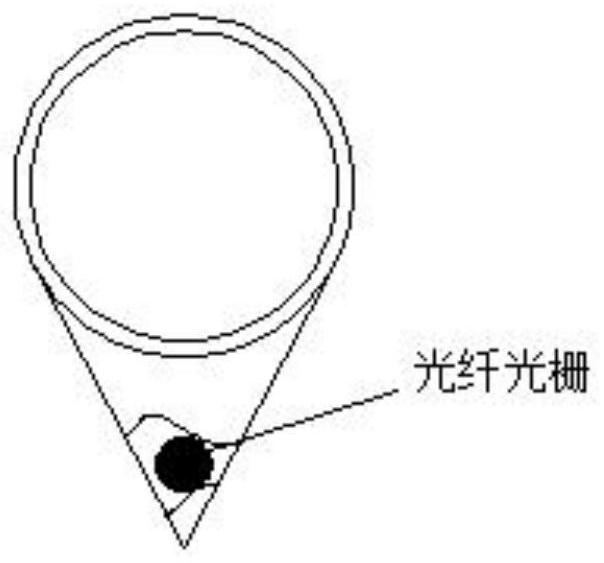

[0030] Step 1: lay a V-shaped groove on the bottom surface of the pipeline for receiving water droplets, lay the fiber grating in the groove inside the V-shaped groove, and lay it along the direction of the pipeline;

[0031] Step 2: The light source of the optical fiber monitoring system transmits signals to the optical fiber in step 1 through the amplifier, and uses the back Rayleigh scattering signal generated when the laser is transmitted in the optical fiber to sense the position of the optical fiber grating during the transmission process. Abnormal signals caused by temperature changes;

[0032] Step 3: Send the abnormal pulse information obtained in step 2 to the monitoring terminal, and display the stored temperature pulse signal WT of each temperature domain of the f...

Embodiment 2

[0043] see Figure 1~2 , in an embodiment of the present invention, a pipeline leakage monitoring method based on fiber Bragg grating temperature measurement technology, comprising the following steps:

[0044] Step 1: lay a V-shaped groove on the bottom surface of the pipeline for receiving water droplets, lay the fiber grating in the groove inside the V-shaped groove, and lay it along the direction of the pipeline;

[0045] Step 2: The light source of the optical fiber monitoring system transmits signals to the optical fiber in step 1 through the amplifier, and uses the back Rayleigh scattering signal generated when the laser is transmitted in the optical fiber to sense the position of the optical fiber grating during the transmission process. Abnormal signals caused by temperature changes;

[0046] Step 3: Transmit the abnormal pulse information obtained in step 2 to the monitoring terminal, display the stored temperature pulse signal WT1 of each temperature domain of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com