ZYNQ7020-based intelligent safety monitoring system for gas turbine unit

A safety monitoring and monitoring system technology, which is applied in gas turbine engine testing, jet engine testing, signal transmission systems, etc., can solve problems such as difficulty in timely discovery, inconvenient construction and installation, and inability to accurately locate the location of gas leakage. Improving the timeliness and accuracy and realizing the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

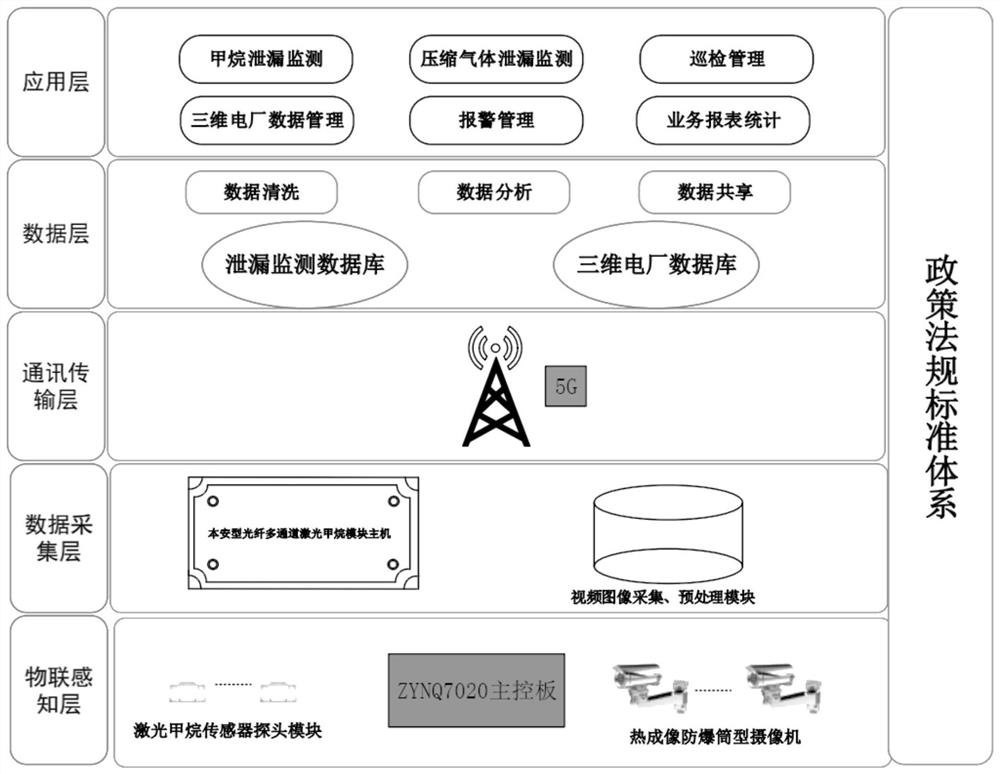

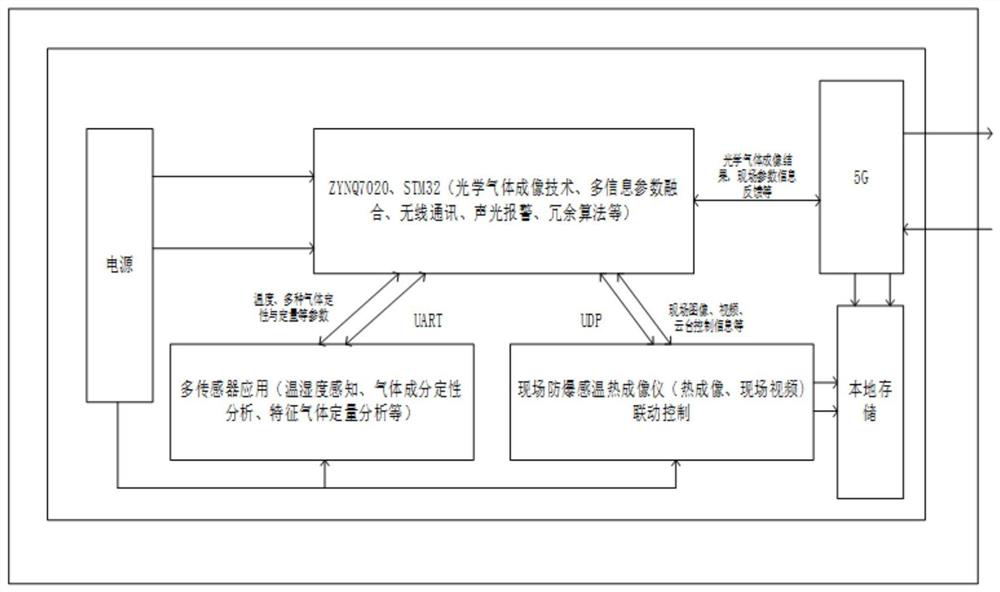

[0030] see Figure 1-3 , an intelligent safety monitoring system for gas units based on ZYNQ7020, the monitoring system includes system architecture and hardware.

[0031] Such as figure 1 As mentioned above, the system architecture includes an application layer, a data layer, a communication transport layer, a data collection layer and an IoT perception layer.

[0032] The application layer mainly includes a gas leakage monitoring system, an inspection management system, a three-dimensional power plant data management system, an alarm management system, and a business statement statistics system. The parameter information and images collected by the equipment are used to evaluate the working status, combined with the location information of the on-site detection points, and finally upload the leakage information, location information and alarm information of the abnormal state detection points to the management center; among them, the gas leakage monitoring system includes m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com