Multi-target robust optimization design method for ultra-efficient induction motor

A multi-objective optimization and induction motor technology, applied in multi-objective optimization, design optimization/simulation, special data processing applications, etc., can solve problems such as complex modeling and low fitting accuracy, and achieve improved robustness and accuracy Sexuality and efficiency, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] In order to have a further understanding and recognition of the structural features and the achieved effects of the present invention, a detailed description is provided in conjunction with preferred implementation examples and accompanying drawings, as follows:

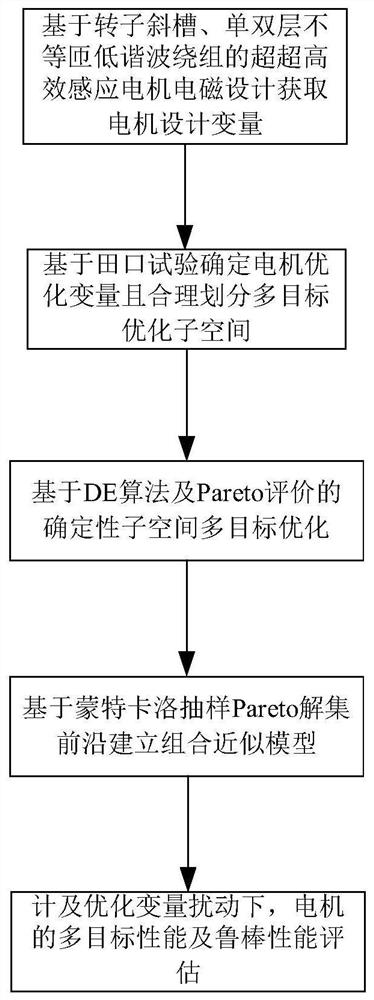

[0092] Such as figure 1 As shown, the multi-objective robust optimization design method of an ultra-ultra-high-efficiency induction motor described in the present invention comprises the following steps:

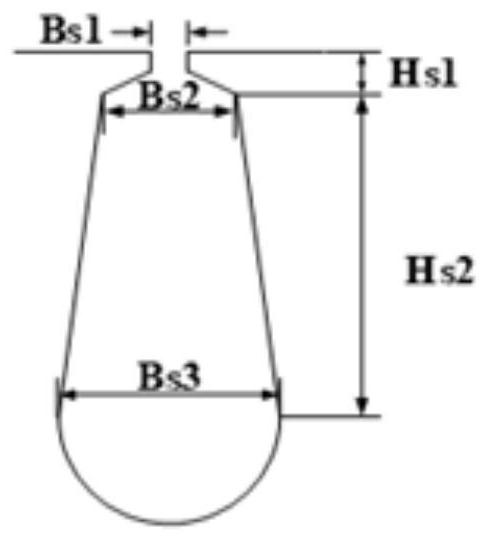

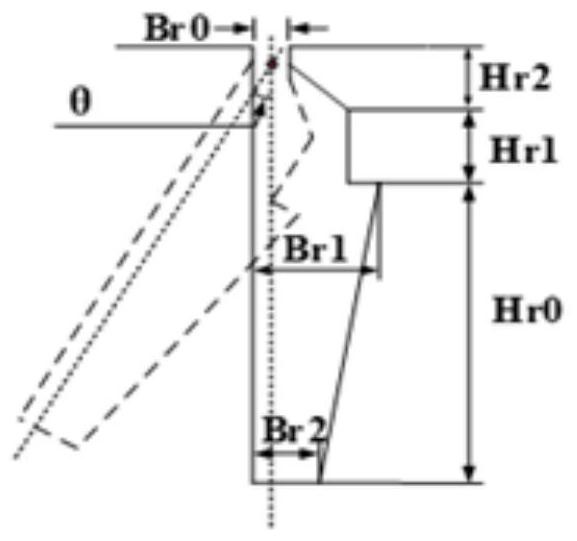

[0093] The first step is to obtain the motor design variables based on the electromagnetic design of the high-efficiency induction motor with rotor chute and single-layer and double-layer unequal-turn low-harmonic winding: according to the technology of using rotor chute and single-layer unequal-turn low-harmonic winding The electromagnetic design scheme of the high-efficiency induction motor, so as to obtain the design variables of the high-efficiency induction motor, and set a reasonable objective function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com