Aqueous hybrid super capacitor

A technology of hybrid supercapacitors and supercapacitors, which is applied in the field of electrochemical energy storage, can solve the problems of short service life of hybrid supercapacitors, and achieve the effects of not being able to last long, being easy to connect in parallel and in series, and having low power costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

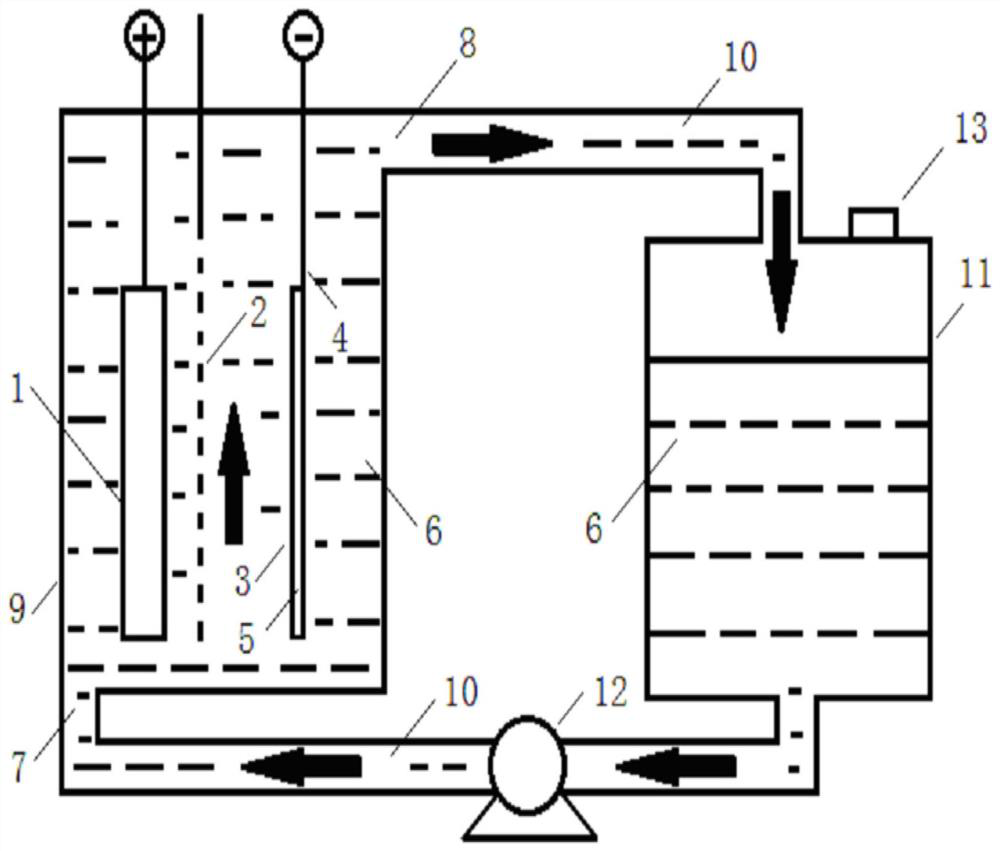

[0062] Supercapacitor positive electrode 1 preparation: the active material is activated carbon with high iodine value, the conductive agent is acetylene black, the binder is polyvinylidene fluoride (PVDF), and N-methylpyrrolidone (NMP) is used as the PVDF solvent; activated carbon: acetylene Black: polyvinylidene fluoride = 80:10:10 mass ratio mixing, adding NMP and stirring to form a membrane-making slurry; coating the mixed slurry on the foamed nickel current collector, hot pressing at 160 degrees Celsius and 10MPa pressure, and drying to form an electrode.

[0063] Gas-evolving electrode 2: Nickel foam is clamped on 80-mesh 304 stainless steel mesh to form a gas-evolving electrode with both oxygen-evolving and hydrogen-evolving activities; zinc negative electrode current collector 4: a brass sheet with a thickness of 0.1 mm; electrolyte 6 is a brass sheet containing 1.5% zinc oxide, 30% potassium hydroxide in water (mass concentration).

[0064] Hybrid supercapacitors asse...

Embodiment 2

[0072] Continue the measurement with the hybrid supercapacitor of Example 1, only change the cycle voltage and recovery charging current conditions, and recalculate the number of cycles.

[0073] Supercapacitor positive electrode 1 and zinc negative electrode 3 charge and discharge cycle: 125 mA / cm 2 Constant current charging to 1.45 volts, 125 mA / cm 2 Constant current discharge to 0.45 volts, repeated 1000 times.

[0074] Zinc negative electrode 3 recovery: use gas-evolving electrode 2 to connect to the positive electrode of the battery tester, and zinc negative electrode 3 to connect to the negative electrode of the battery tester to charge; 15 mA / cm 2 Charge at a constant current for 1 hour to electrodeposit metal zinc on the zinc negative electrode 3 to restore capacity.

[0075] Every 14 hours of working of the hybrid supercapacitor, turn off the battery tester and the electrolyte 12 and let it stand for 10 hours before continuing to work; every time about 1000 charging...

Embodiment 3

[0077] Supercapacitor positive electrode 1 preparation: the nickel foam current collector in the preparation of the supercapacitor positive electrode 1 in Example 1 was changed to a 350-mesh 304 stainless steel current collector, and the others were the same.

[0078] Gas-evolving electrode 2: 80-mesh 304 stainless steel mesh; negative collector 4: a brass sheet with a thickness of 0.1 mm; electrolyte 6 is an aqueous solution of 6 mol / L potassium hydroxide containing saturated zinc oxide, containing 100 ppm indium sulfate.

[0079] The assembly of the hybrid supercapacitor is the same as in Example 1.

[0080] Preparation of zinc negative electrode 3: connect the positive electrode of the battery tester with the gas-evolving electrode 2, and connect the negative electrode with the zinc negative electrode current collector 4; 20mA / cm 2 Constant current charging for 4 hours.

[0081] Supercapacitor positive electrode 1 and zinc negative electrode 3 charge and discharge cycle: 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com