GH2132 alloy and preparation method thereof

A GH2132 alloy technology, applied in the field of metal material preparation, can solve the problem that the yield strength of GH2132 alloy is difficult to further increase, and achieve the effects of shortening the production cycle, increasing the yield strength, and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for preparing a GH2132 alloy, which specifically includes the following steps,

[0055] Put the raw materials of GH2132 alloy at 1510°C for vacuum melting, and then cast them into ingots; then carry out electroslag remelting of the ingots, control the working current 8000A, voltage 60V, the slag used is CaF 2 -AlO-CaO-MgO, the remelted ingot is forged and billeted, and a 130mm×130mm square billet is obtained after air cooling; wherein, the initial forging temperature of forging billet is 1050°C, and the final forging temperature is 950°C.

[0056] Grind the surface of the billet clean to make it bright and smooth without any defects such as cracks visible to the naked eye, then heat to 1000°C, preheat for 100 minutes, then heat to 1210°C, soak at 1210°C for 140 minutes, and then control the initial rolling The temperature is 1090°C, and hot rolling is carried out for multiple passes until it is rolled into a Ф13 wire rod; the final roll...

Embodiment 2

[0060] This example provides a method for preparing a GH2132 alloy. The difference from Example 1 is that this example changes the holding time of the intermediate pretreatment from 30 minutes to 60 minutes, and the others are the same as Example 1.

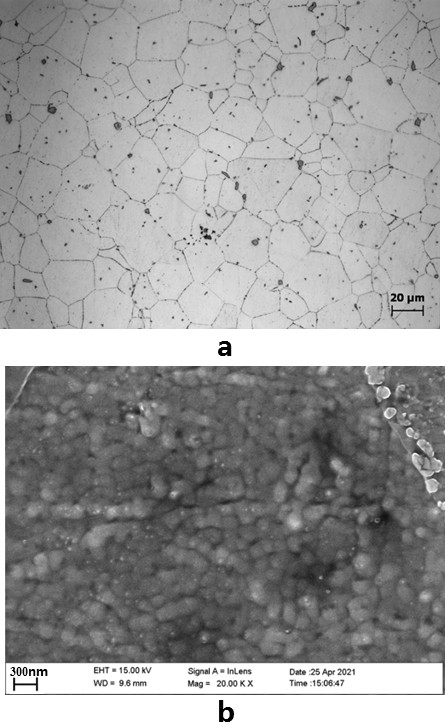

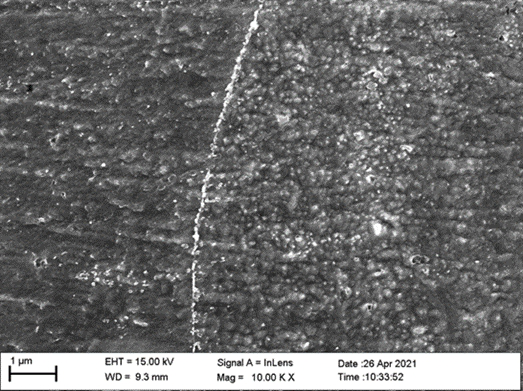

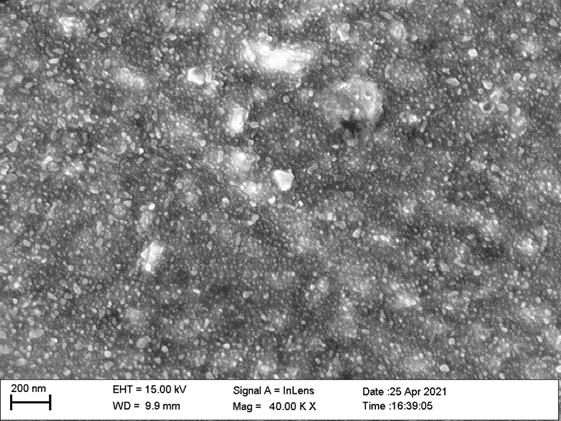

[0061] Figure 4 is the SEM image of the alloy material after intermediate pretreatment, indicating that the alloy sample with γ' phase precipitation is obtained after intermediate pretreatment; Figure 5 It is the SEM picture of the alloy material after aging heat treatment, indicating that after aging heat treatment, a large number of alloy materials with γ' phase precipitation in the size of 20-30mm have been obtained.

Embodiment 3

[0063] This example provides a method for preparing a GH2132 alloy. The difference from Example 1 is that in this example, the temperature of the intermediate pretreatment is changed from 650°C to 600°C, and the others are the same as in Example 1.

[0064] Alloy samples with γ' phase precipitation were obtained after intermediate pretreatment, and a large amount of alloy materials with γ' phase precipitation were obtained after aging heat treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com