Y-shaped ventilation working face goaf top pipe gas extraction method

A gas extraction and goaf technology, which is applied in the field of gas extraction in goafs, can solve the problems of difficult intubation construction, low extraction efficiency, etc., to reduce construction difficulty and construction cost, prevent gas concentration from exceeding the limit, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

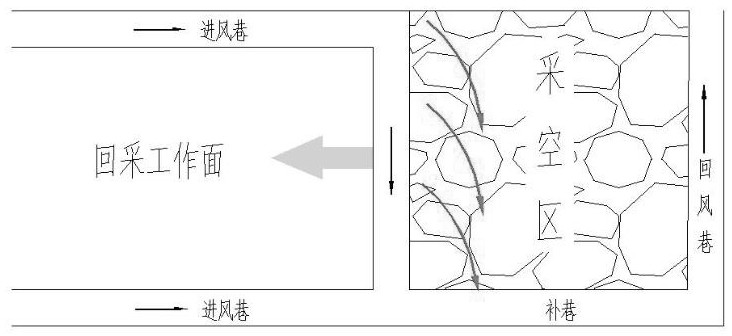

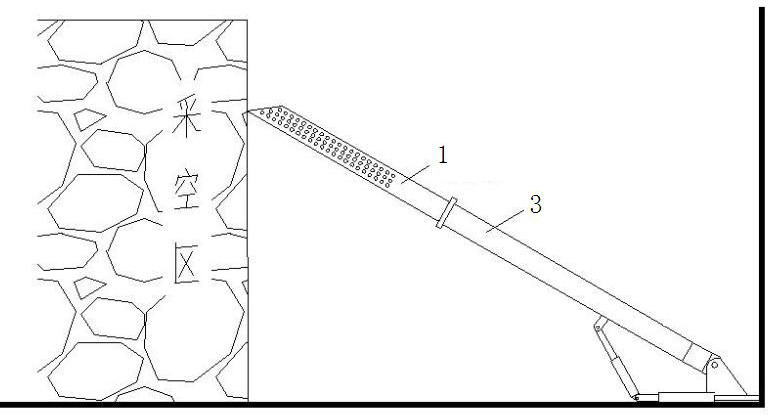

[0023] A working face adopts Y-shaped ventilation mode, and the gas in the goaf is affected by the wind flow in the inlet roadway, and escapes to the side of the supplementary roadway, causing the gas concentration in the supplementary roadway to exceed the limit. In order to solve the problem of over-limit gas concentration in supplementary roadways, the pipe-jacking gas extraction device and method in the goaf of the Y-shaped ventilated working face will be used to solve the problem of over-limit gas concentration in supplementary roadways.

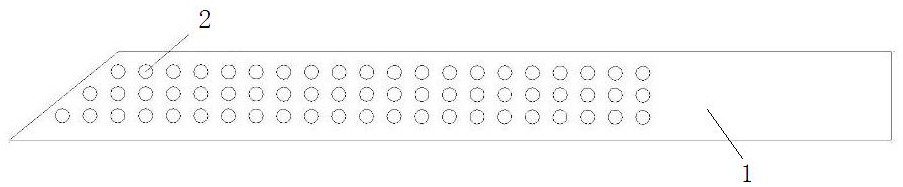

[0024] As shown in the figure, the pipe jacking device in the goaf of the Y-shaped ventilated working face proposed in this example includes a special spiral welded steel pipe and a telescopic jack.

[0025] The diameter of the spiral steel pipe is DN200, the length is 2m, the front end of the steel pipe is tapered, and the first 1.5m of the steel pipe is uniformly screened; the telescopic jack is selected according to the parameters suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com