A fume-free hood digester

A digester and fume hood technology, which is applied to chemical instruments and methods, smoke and dust removal, and separation of dispersed particles, can solve the problems of lower product penetration rate, large space occupation, and inconvenient operation, so as to reduce the risk of air pollution, The effect of prolonging the service life and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the drawings and embodiments.

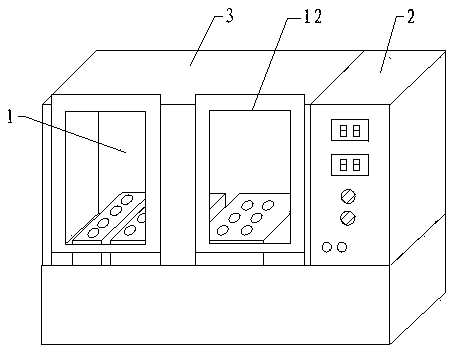

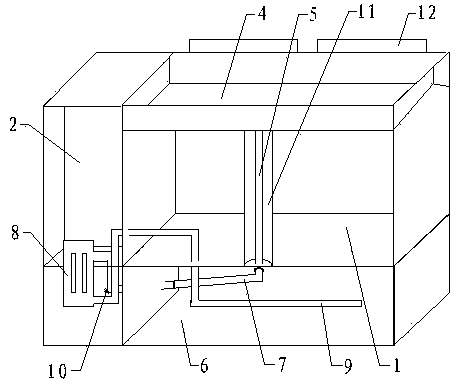

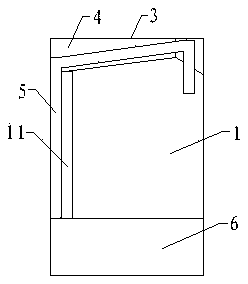

[0021] Such as Figure 1-5 Shown: A fume hood-free digester, including a closed digestion chamber 1 and a control motor 2 electrically connected to it. The digestion chamber 1 is equipped with a digester and corresponding cooling pipe racks, made of PVC board The enclosed digestion room 1 protects the digestion system to prevent exhaust gas (SO 4 , NO 2 Etc.), and the front of the digestion chamber 1 is provided with a double-opening upper lift door 12. A closed top cover 3 is provided above the digestion chamber 1, and a sandwich cavity 4 is formed between the top cover 3 and the upper wall of the digestion chamber 1. The upper wall of the digestion chamber 1 is the bottom of the sandwich cavity 4 The back is long and the front is short; there is a high-pressure corrosion-resistant fan 8 on the back side of the control motor 2. The suction port of the high-pressure cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com