Vacuum system and process for distillation tower for producing three-mixed fraction reduced pressure tar

A vacuum system and distillation tower technology, which is applied in the field of metallurgical coking, can solve the problems of the quality of washing oil, unqualified, and the quality of three-mixed fractions, and achieve the effect of increasing the replacement cycle, ensuring the pumping capacity, and ensuring the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]DETAILED DESCRIPTION OF THE INVENTION The specific embodiments of the present invention will be further described below with reference to the accompanying drawings:

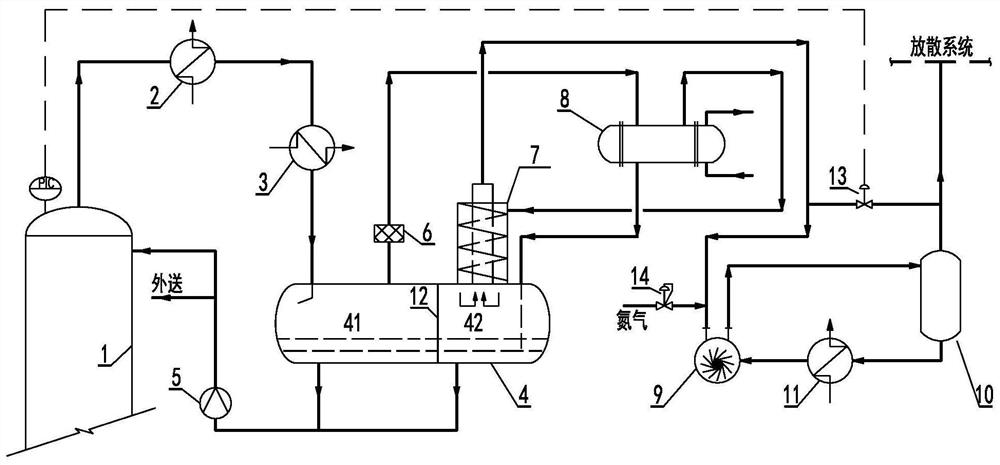

[0028]Such asfigure 1As shown, a vacuum system for 3 mixed fraction reduced pressure tar is included, including a double chamber reflow groove 4, a vacuum cyclone trap 7 and a vacuum cooler 8.

[0029]The double chamber reflow groove 4 is separated from two separate chambers 41 and two chambers 42, and the two chambers 42 and the vacuum cyclone trap 7 are directly connected, and the chambers 41, the second chamber 42 passes through the pipe and the vacuum cooler 8. Connecting, the vacuum cyclone trap 7 is connected to the vacuum cooler 8 via a pipe, and the vacuum cyclone trap 7 is connected to the discharge system. The reduced pressure tar distillation column 1 column top is connected to one chamber 41, and the decompression tar distillation column 1 tower is provided with a raw material tar / tri-oil heat exchanger 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com