Expanded feed belt drying machine and airflow path arrangement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

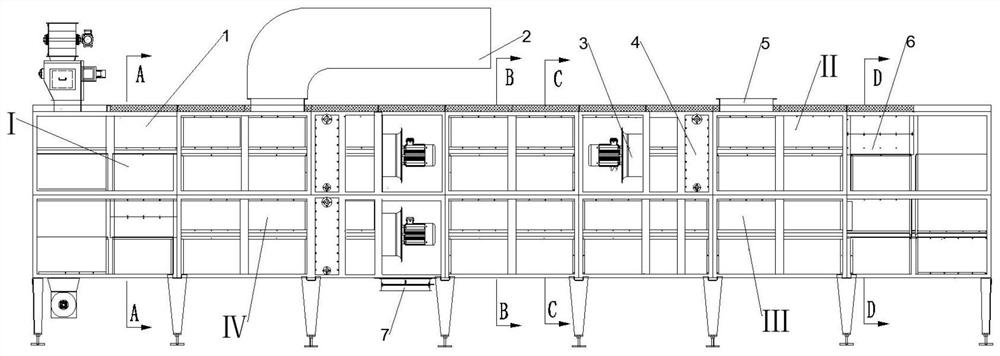

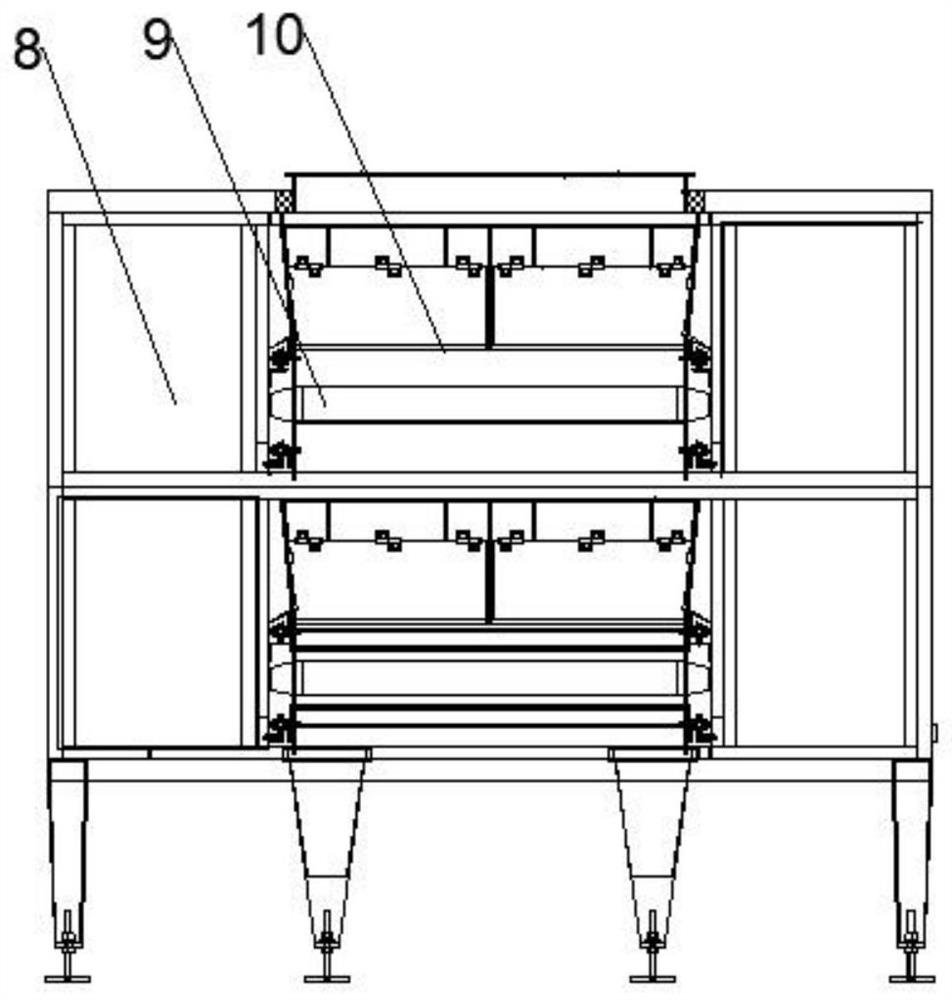

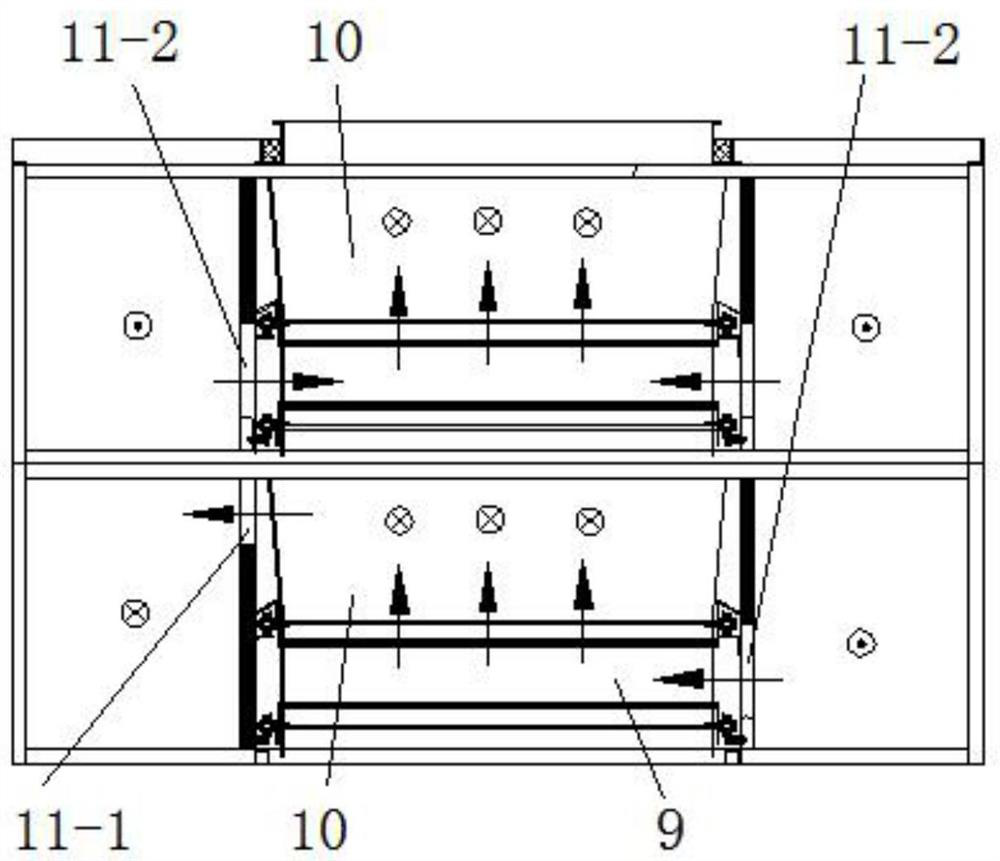

[0065] Such as Figure 1-9 As shown, this embodiment provides an extruded feed belt dryer, which mainly includes a closed box 1, a material drying area 10, an air duct 8, a material conveyor belt 9 and a windshield 6 arranged in the material drying area 10. The closed box body 1 is provided with a feed end and a discharge end, and between the feed end and the discharge end are successively provided with an initial drying section, a constant-speed drying section and a decelerating drying section; the initial drying section, constant Both the quick-drying section and the decelerating drying section are provided with a material drying area 10, and both sides of any material drying area 10 are provided with an air duct 8, and the material drying area 10 and the air duct 8 in the adjacent section are Continuously distributed; the material conveyor belt 9 runs through the material drying zone 10 of the initial drying section, the constant speed drying section and the decelerating dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com