Outdoor high-voltage vacuum circuit breaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

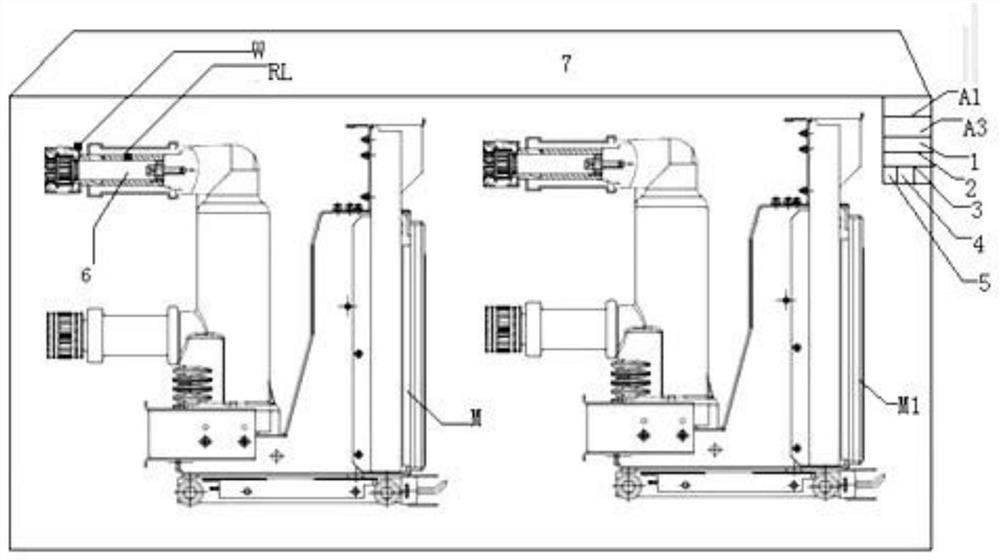

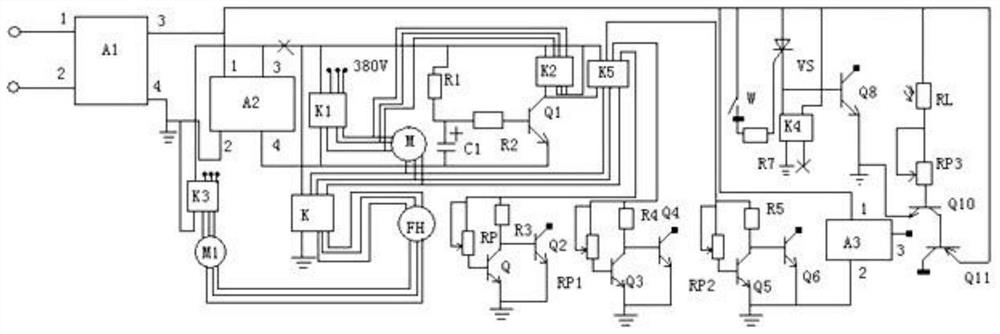

[0016] figure 1 , 2 As shown, an outdoor high-voltage vacuum circuit breaker includes a stabilized power supply A1, a high-voltage vacuum circuit breaker body M, a spare high-voltage vacuum circuit breaker M1, a prompt circuit A3, and a time circuit 1, a contact detection circuit 2, and a temperature detection circuit. 3. The arc detection circuit 4 and the delay circuit 5; the arc detection circuit 4 and the temperature detection circuit 5 are equipped with a photosensitive resistor RL and a temperature switch W respectively, and the photosensitive resistor RL is bonded to the body of the high voltage vacuum circuit breaker with transparent adhesive The outer end of the glass vacuum interrupter 6, and the light-receiving surface of the photoresistor RL faces the inner end of the interrupter, and the temperature switch W is installed on the outer end of the static contact of the high-voltage vacuum circuit breaker body M, and its temperature-sensing surface is close to The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com