Automatic loading device for nut hot-heading procedure

An automatic feeding and process technology, which is applied to nuts, operating devices, forging/pressing/hammer devices, etc., can solve the problems of uncertain displacement of nuts, uneven heating, and difficult to control heating time, and achieve precise heating treatment, The effect of improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

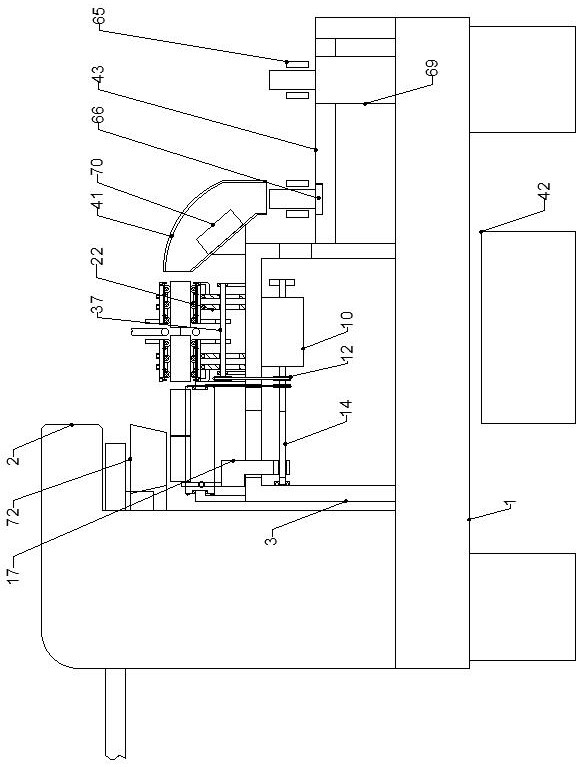

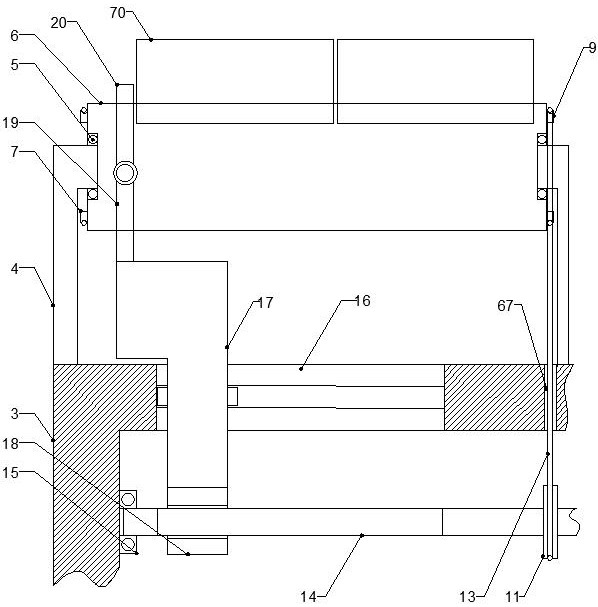

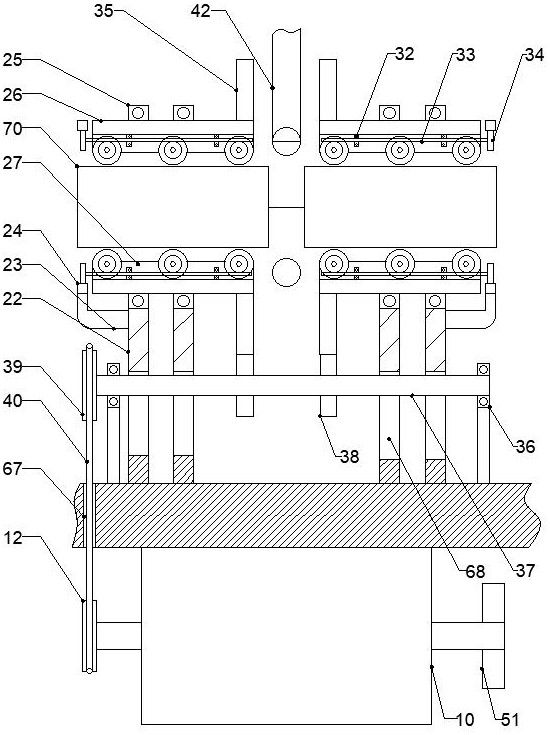

[0029] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-13 As shown in the figure, an automatic feeding device for the nut hot pier process, including a rectangular base 1 and a cutting machine 2, one end of the upper surface of the rectangular base 1 is equipped with a clamping displacement mechanism, and the other end of the upper surface of the rectangular base 1 is equipped with a heating pad Mechanism, the side of the material heating mechanism is equipped with an intermittent feeding mechanism;

[0030]The intermittent feeding mechanism includes a 匚-shaped support plate 3 installed on the upper surface of the rectangular base 1. A bearing bracket 4 is installed on the upper surface of the 匚-shaped support plate 3. There are two pairs of bearing brackets 4, and a roller bearing 5 is installed on the upper end of the bearing bracket 4. , the outer ring of the roller bearing-5 is equipped with a rotating roller 6, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap