Cam fillet milling optimization design method for camshaft

An optimized design and cam circle technology, which is applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of no mature solution, accelerated blade wear, and difficult processing, etc., to ensure first-time success and improve effectiveness , reducing the effect of limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

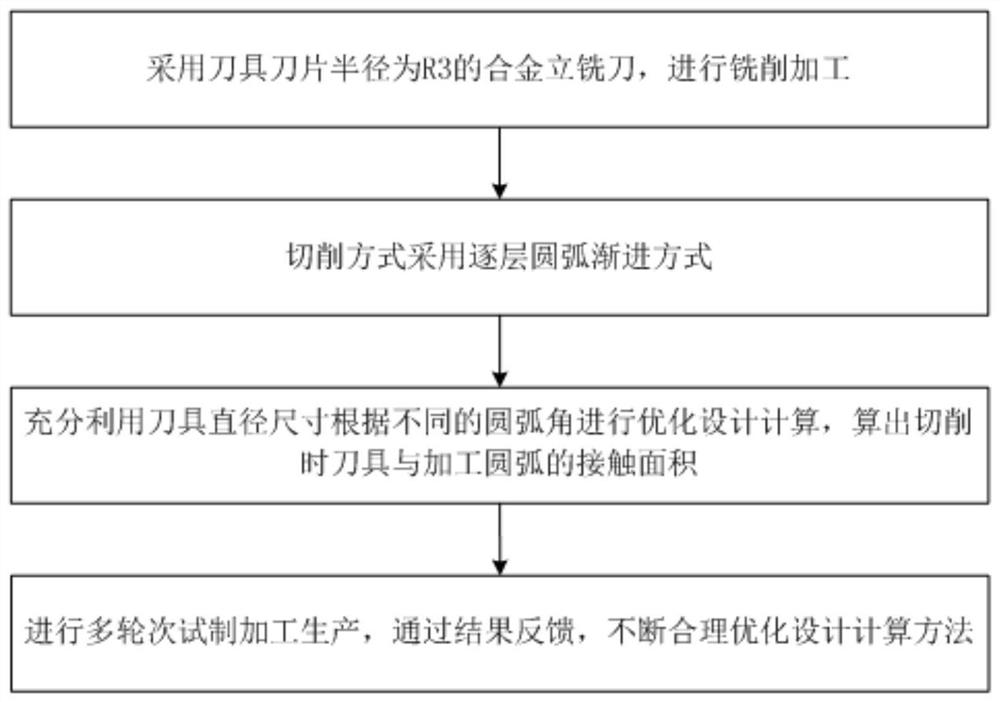

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0023] Optimal design calculation is a design method for selecting the best solution from various schemes and calculating it. It is based on the optimization theory in mathematics, using computer as a means, according to the performance goals pursued by the design, establishes the objective function, and seeks the optimal design scheme under various given constraints. The invention is mainly aimed at the optimization design calculation of the cam fillet milling process of the camshaft.

[0024] Ordinary cam fillet size requirements are R1-R3, and the processing fillet is small. Using the conventional cam fillet milling optimization design calculation can basically guarantee the consiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com