Transportation equipment for power cable line construction

A technology for transportation equipment and power cables, which is applied in the field of transportation equipment for power cable line construction, can solve the problems of inability to adjust the height of baffles on both sides of the bobbin according to the actual situation, the height of the baffles cannot be adjusted, and the practicability is not high. The effect of high space utilization, improved practicability and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

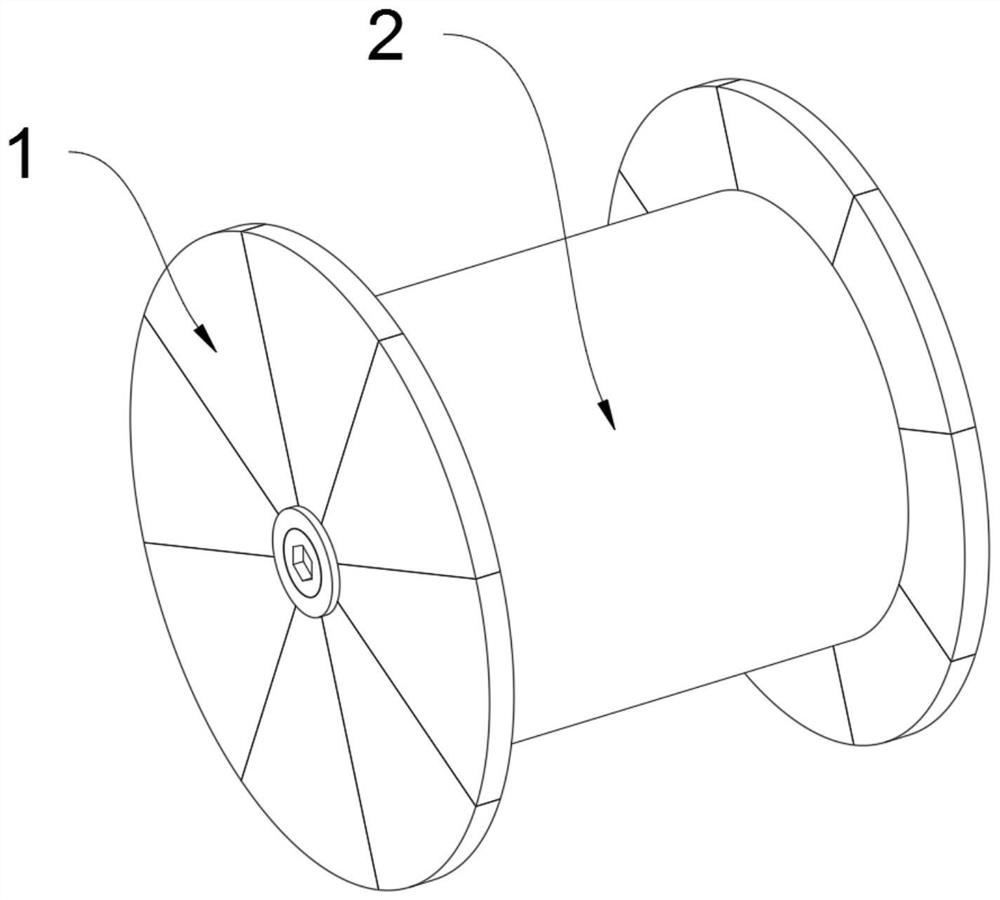

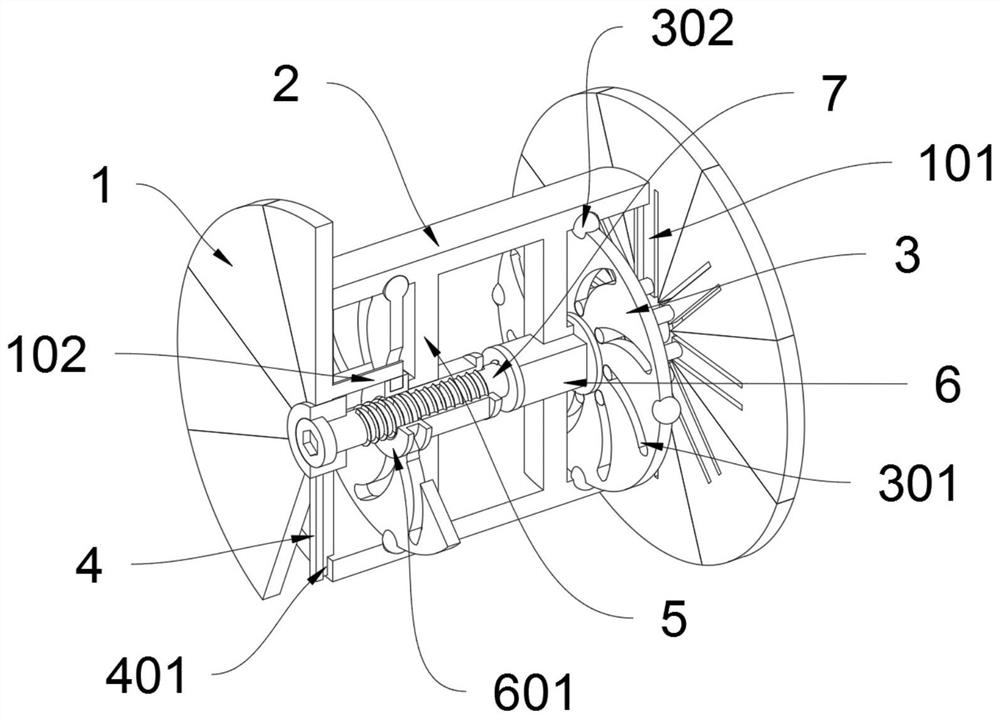

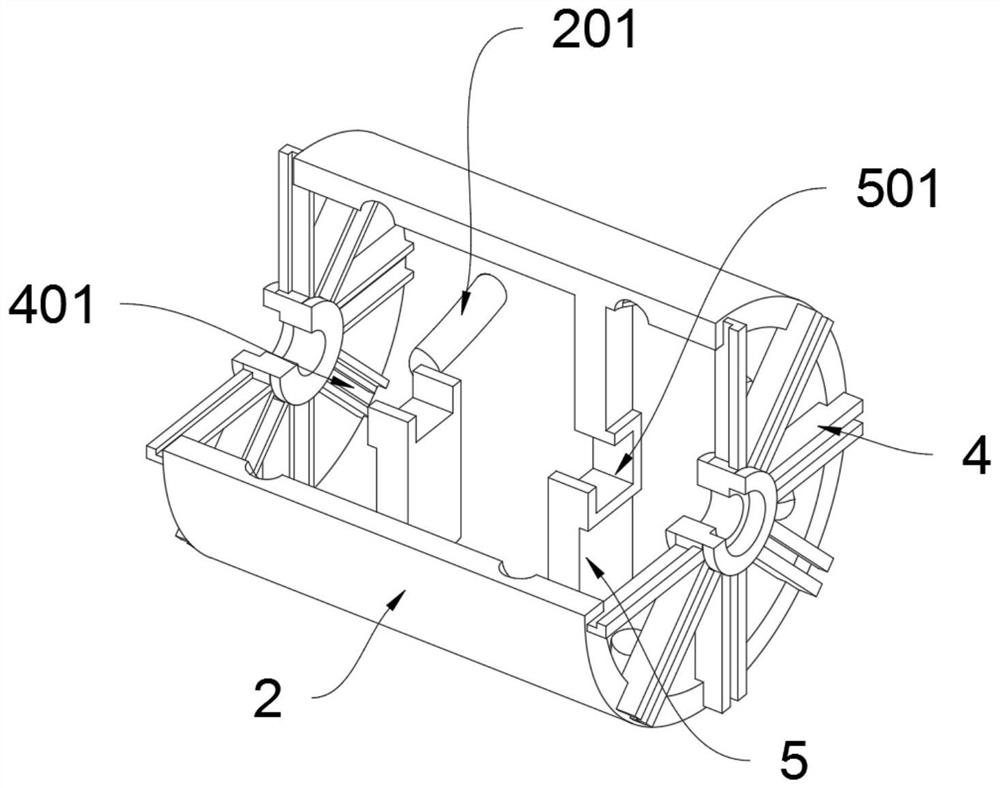

[0034] as attached figure 1 to attach Figure 7 Shown:

[0035]The invention provides a transportation equipment for power cable line construction, which includes a line retaining side plate 1, a winding drum 2, a linkage control panel 3, a positioning track column 5, a positioning push block 6 and a master control adjustment lever 7; the line retaining side plate 1 is plugged on the divergent track column 4; the two sides of the winding drum 2 are fixedly connected with divergent track columns 4; the linkage control panel 3 is plugged into the inside of the cylinder body of the twine winding drum 2; the outer side of the linkage control panel 3 is set There is a positioning protrusion 302, and the inner wall of the cylinder of the winding drum 2 is provided with a positioning groove 201. The shape of the groove body of the positioning groove 201 is helical, and the positioning protrusion 302 is inserted into the inside of the positioning groove 201. This design makes the lin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap