Automatic circulating water supply system for cooling water of dry quenching water seal

A technology of automatic circulation and water supply system, applied in the field of coking, can solve the problems of reducing the service life of water point equipment, increasing the labor intensity of workers, uneconomical discharge, etc. dirt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

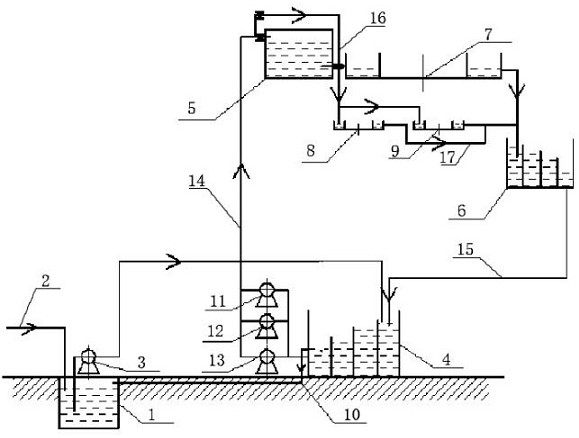

[0029] The pump group includes a first pressurization pump 11, a second pressurization pump 12 and an emergency pump 13, and the first pressurization pump 11, the second pressurization pump 12 and the emergency pump 13 all connect the main multi-stage filter water tank 4 through the pipeline a14. Reclaimed water is supplied into the accident water tank 5;

[0030] Specifically, the emergency water tank 5 can be supplied with water by the first booster pump 11, the second booster pump 12 and the emergency pump 13, wherein the emergency pump 13 has a backup power supply, which can be started using the backup power supply in the event of a power failure, thereby Avoid the phenomenon of water cut-off when the power is cut off. When the power is not cut off, water can be supplied by the first booster pump 11 and the second booster pump 13 .

[0031] The inside of the main multi-stage filter water tank 4 and the auxiliary multi-stage filter water tank 6 are provided with sedimentati...

Embodiment 2

[0033] Wherein, the auxiliary multi-stage filtered water tank 6 supplies water to the main multi-stage filtered water tank 4 through the pipeline b15, wherein one end of the pipeline b15 is installed at the bottom sedimentation cavity of the auxiliary multi-stage filtered water tank 6, and the other end is installed at the bottom of the main multi-stage filtered water tank 4 The top position of the high sedimentation chamber can introduce the relatively clean water source in the auxiliary multi-stage filter water tank 6 into the main multi-stage filter water tank 4 for sedimentation and filtration, and the circulation in turn can ensure the cleanness of the water source entering the accident water tank 5;

[0034] The accident water tank 5 supplies water to the furnace top water seal tank 7, the dust removal emergency water seal tank 8 and the CDQ emergency water seal tank 9 through the pipeline c16, and the furnace top water seal tank 7, the dust removal emergency water seal ta...

Embodiment 3

[0036] The main multi-stage filter water tank 4 is equipped with a float switch inside. The float switch controls the liquid level of the water tank through the central control. Carry out automatic water replenishment; when the float switch detects that the liquid level is higher than the set liquid level, stop the water replenishment pump 3 through the central control to replenish water;

[0037] The central control can be PLC, which sets the liquid level data threshold. When the float switch detects that the liquid level value is lower than the threshold, the PLC will control the replenishment pump 3 to automatically replenish water to the main multi-stage filter water tank 4; when the float switch detects When the liquid level value is higher than the threshold value, the PLC will control the supplementary water pump 3 to stop working, so as to avoid the overflow of the main multi-stage filter water tank 4;

[0038] The top position of one side of the main multi-stage filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com