High-pressure high-position self-circulation water delivery energy storage multi-stage power station and power generation method thereof

A self-circulation, power station technology, applied in the field of power stations, can solve the problems of large manpower, material and financial resources, existence of nearby residents, long construction period, etc., to shorten the construction period, reduce flood damage, and shorten the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

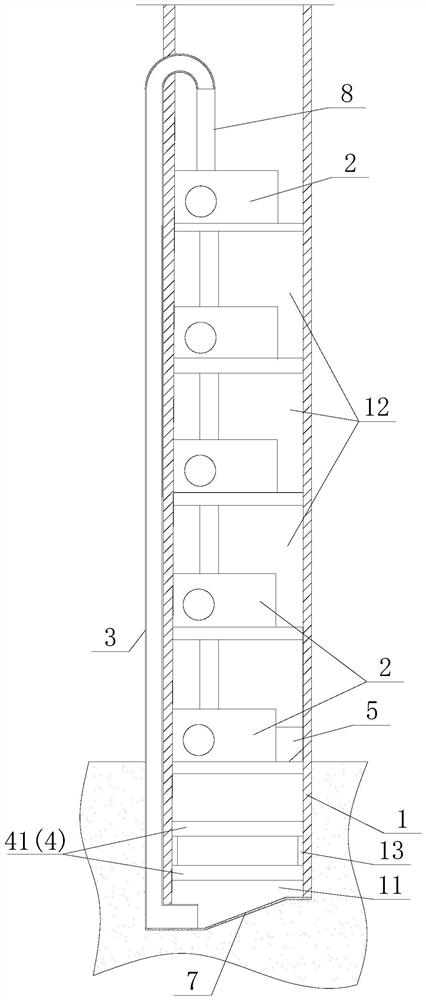

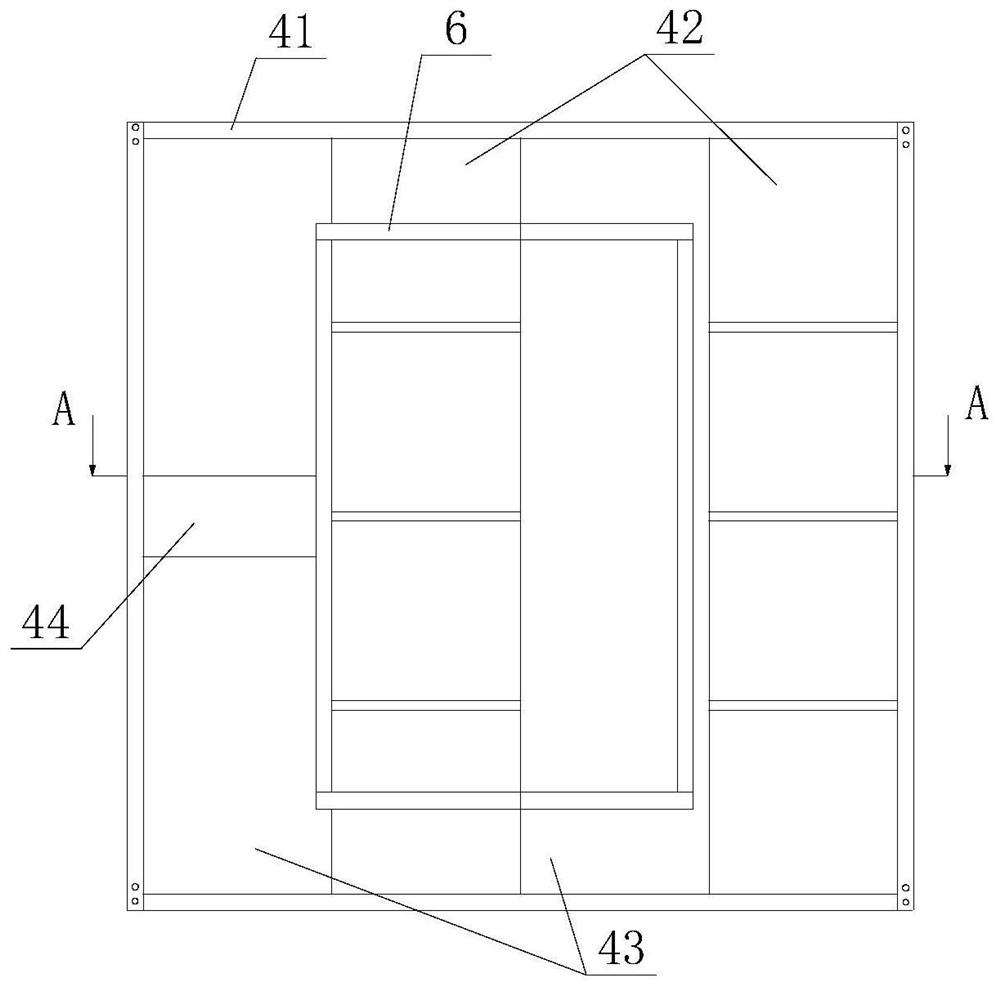

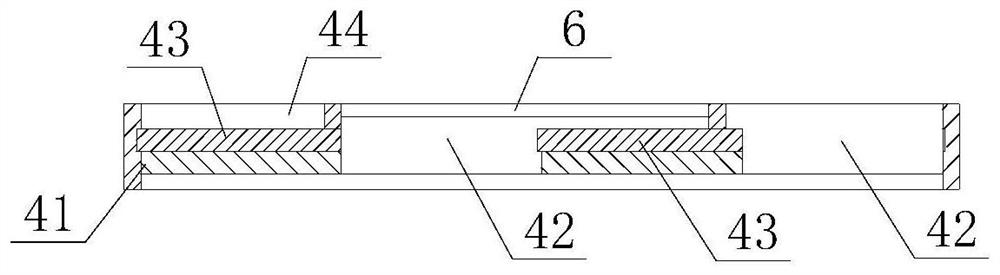

[0035] Figure 1 to Figure 5 It shows an embodiment of the high-voltage high-level self-circulating water transmission and energy storage multi-stage power station of the present invention. The high-voltage high-level self-circulation water transmission and energy storage multi-stage power station includes a pool 1, and the bottom of the pool 1 is provided with a pressurized water chamber 11 , the pool 1 is provided with a multi-layer connected power generation chamber 12 above the pressurized water chamber 11, the pressurized water chamber 11 communicates with the lowermost power generation chamber 12, and each power generation chamber 12 is equipped with a hydraulic turbine generator set 2, and the pressurized water chamber The bottom of 11 is connected to the water inlet of the uppermost water turbine generator set 2 through the water delivery pipe 3, and the continuous water pressure mechanism 4 is arranged in the pressure water chamber 11, and the continuous water pressure...

Embodiment 2

[0070] A high-voltage high-level self-circulating water transmission and energy storage multi-stage power generation method of Embodiment 1 includes the following steps:

[0071] S1: Pool 1 is filled with water;

[0072] S2. Continuous pressurized water: The up and down pressurized water platform 41 rises and falls alternately, and the water in the pressurized water chamber 11 is continuously pressurized and sent to the uppermost hydraulic turbine generator set 2 through the water delivery pipe 3, so that each hydraulic turbine generator set 2 is moved from the upper Continuous water supply and power generation down to the bottom; the door body 43 is opened during the up and down process of the up and down pressurized water platform 41, and the door body 43 is closed during the down process. The lifting and lowering water platform 41 descends under the effect of water weight and dead weight.

[0073] The specific water pressure process is as follows: firstly, the lower liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com