Sand and scale prevention oil well pump

An oil pump and anti-scaling technology, which is applied to pumps, parts of pumping devices for elastic fluids, pump devices, etc., can solve problems such as single function, mud and sand clogging, and oil scale deposition, and achieve high automation and ingenious structure , Grease cleaning and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

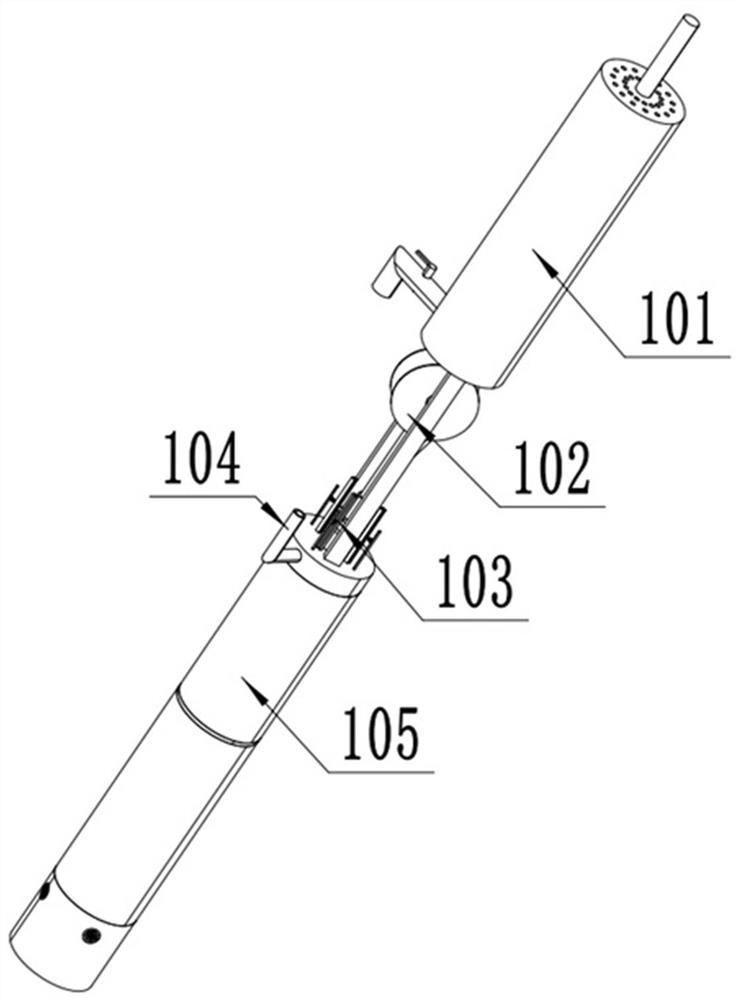

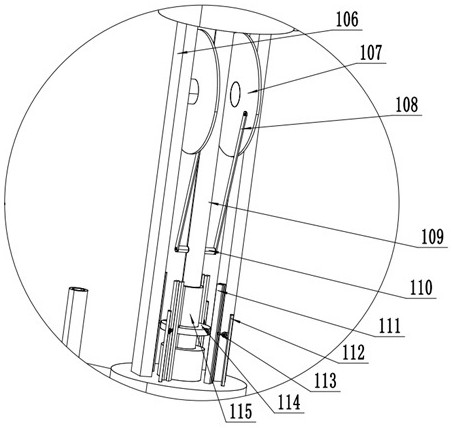

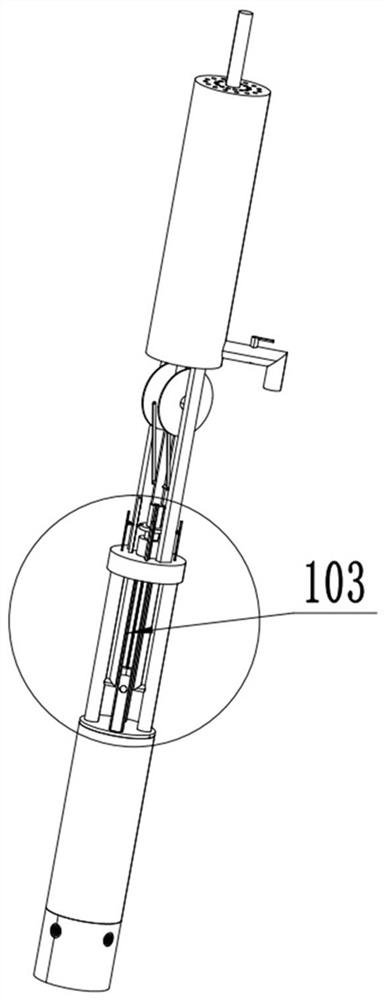

[0023] Example: such as figure 1 , figure 2 , Figure 7 As shown, a kind of anti-sand and anti-scaling oil well pump includes an oil storage device 101, a driving device 102, a softener injection device 103, a pump body shell 105, an oil delivery pipe 109, and an oil pumping device 126, and the oil pumping device 126 is arranged on the pump body shell 105, the first end of the oil delivery pipe 109 is fixedly connected to the scraper 128 in the oil pumping device 126, the second end of the oil delivery pipe 109 is slidably arranged inside the oil storage device 101, and the driving device 102 is installed on the oil storage device 101 and the pump casing 105, the driving device 102 drives the oil delivery pipe 109 to slide, and then the oil delivery pipe 109 controls the action of the oil pumping device 126, changes the internal space of the oil pumping device 126, and realizes oil pumping. The softener injection device 103 is installed inside the pump casing 105, and the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com