Damper suitable for rotor bearing system

A damper and bearing technology, applied in springs/shock absorbers, non-rotational vibration suppression, vibration suppression adjustment, etc., can solve problems such as non-adjustment and failure to achieve vibration reduction effects, achieve replaceable operations, and avoid instability , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

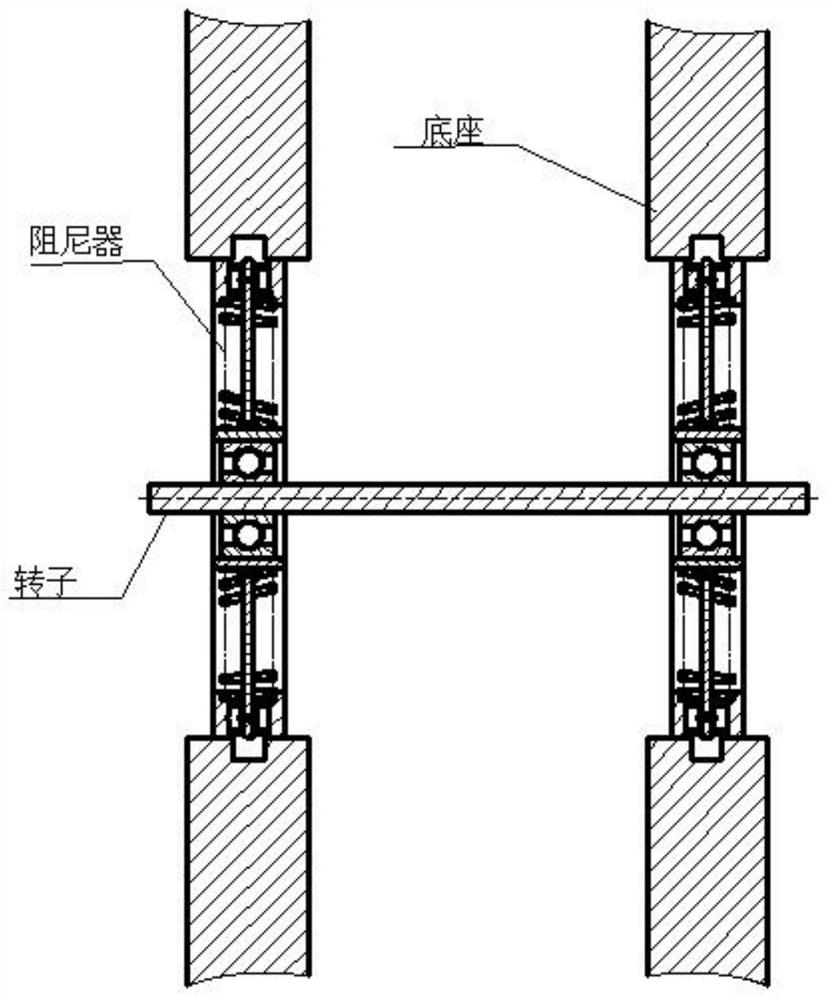

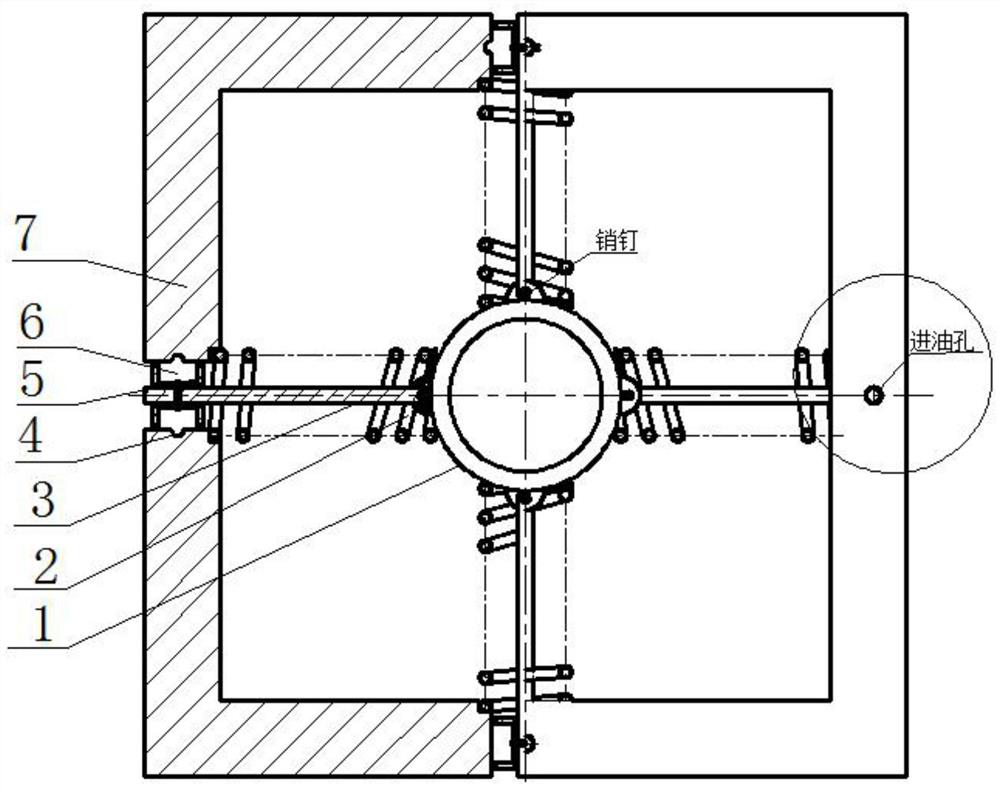

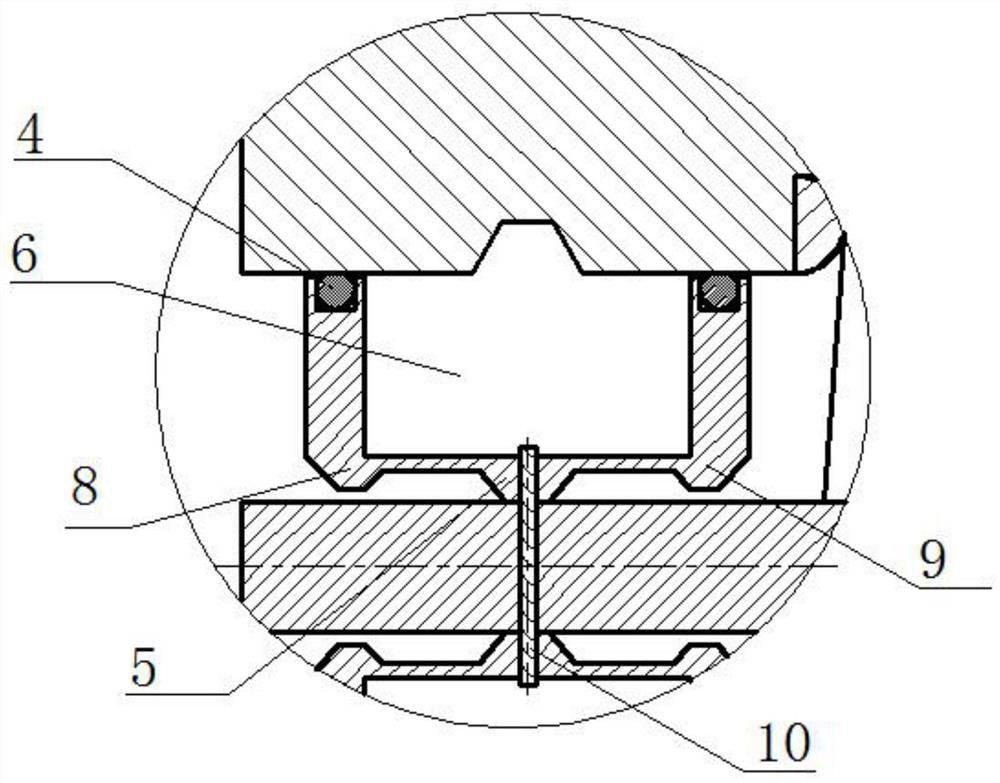

[0026] combine figure 1 -2, figure 1 In , the relationship between the installation position of the additional system (a new type of broadband adjustable damper) and the main system is given. Figure 2a And Figure 5 shows the assembly diagram and three-dimensional diagram of the additional system, including connecting piece 1, spring 2, elastic column 3, O-ring 4, adjustable friction ring 5, support base 7 and so on. It includes a sealing chamber 6, which is an annular sealing chamber formed by sealing the outer ring of the friction ring and the through hole of the support base through two O-rings.

[0027] Such as figure 1 As shown, the additional system restricts the rotation of the outer ring of the bearing through the interference fit between the hole of the connector and the outer ring of the rolling bearing, and the spring acts as a support to limit the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com