Double-arc curved surface harmonic drive speed reducer

A technology of harmonic drive and reducer, applied in the direction of transmission, transmission parts, belt/chain/gear, etc., can solve the problems of tooth root fracture, limited bearing capacity, easy stress concentration, etc., to extend service life, improve The effect of carrying capacity and improving transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is attached Figure 1-3 The application is described in further detail.

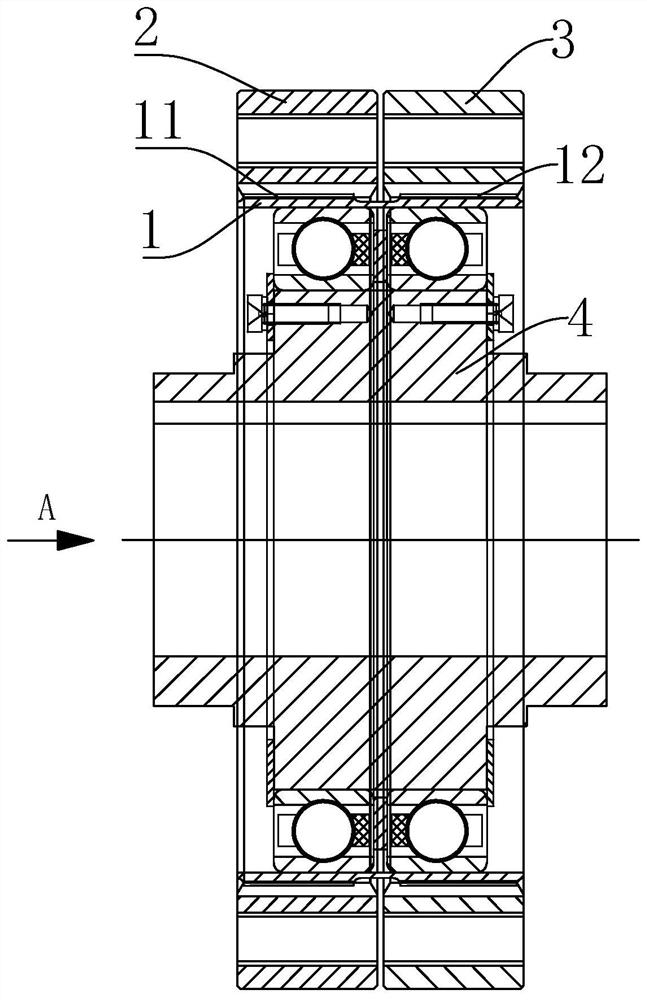

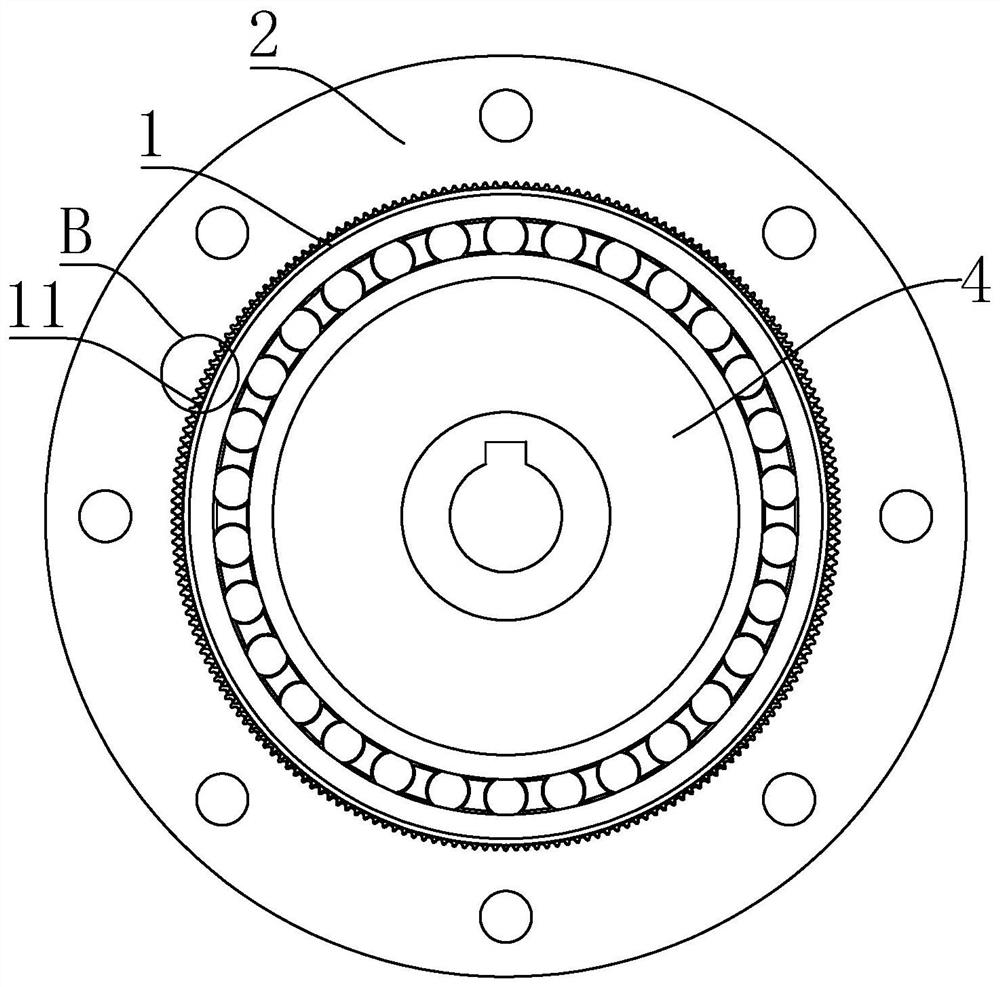

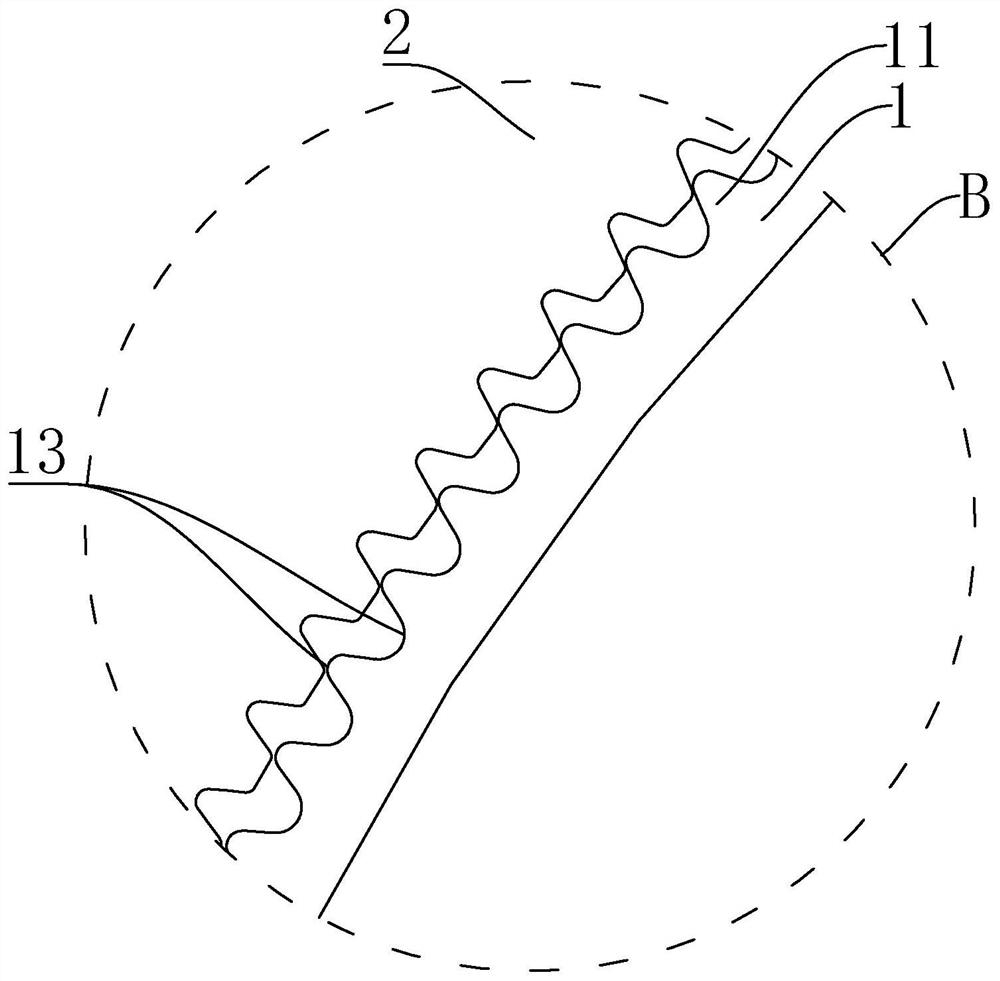

[0031] Such as figure 1 As shown, a double-arc surface harmonic drive reducer of the present application includes a flexspline 1, an input steel pulley 2, an output steel pulley 3 and a wave generator 4. The wave generator 4 is arranged inside the flexspline 1, and the flexspline 1 adopts a double-arc curved tooth profile, and the outer side of the flexspline 1 is provided with external teeth. The external teeth of the flexspline 1 include coaxial first-stage external teeth 11 and second-stage external teeth 12. The first-stage external teeth 11 and the second-stage external teeth The second-stage external teeth 12 are respectively located on both sides of the flexspline 1, the first-stage external teeth 11 of the flexspline 1 mesh with the internal teeth of the input steel wheel 2, the second-stage external teeth 12 of the flexspline 1 and the output steel wheel 3 The internal tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com