Ultrasonic vibration auxiliary milling force modeling method based on finite element simulation

A technology of ultrasonic vibration and modeling methods, applied in design optimization/simulation, instruments, electrical digital data processing, etc., can solve problems such as complex models, high calculation costs, and inaccurate simulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the examples of the present invention. , embodiment:

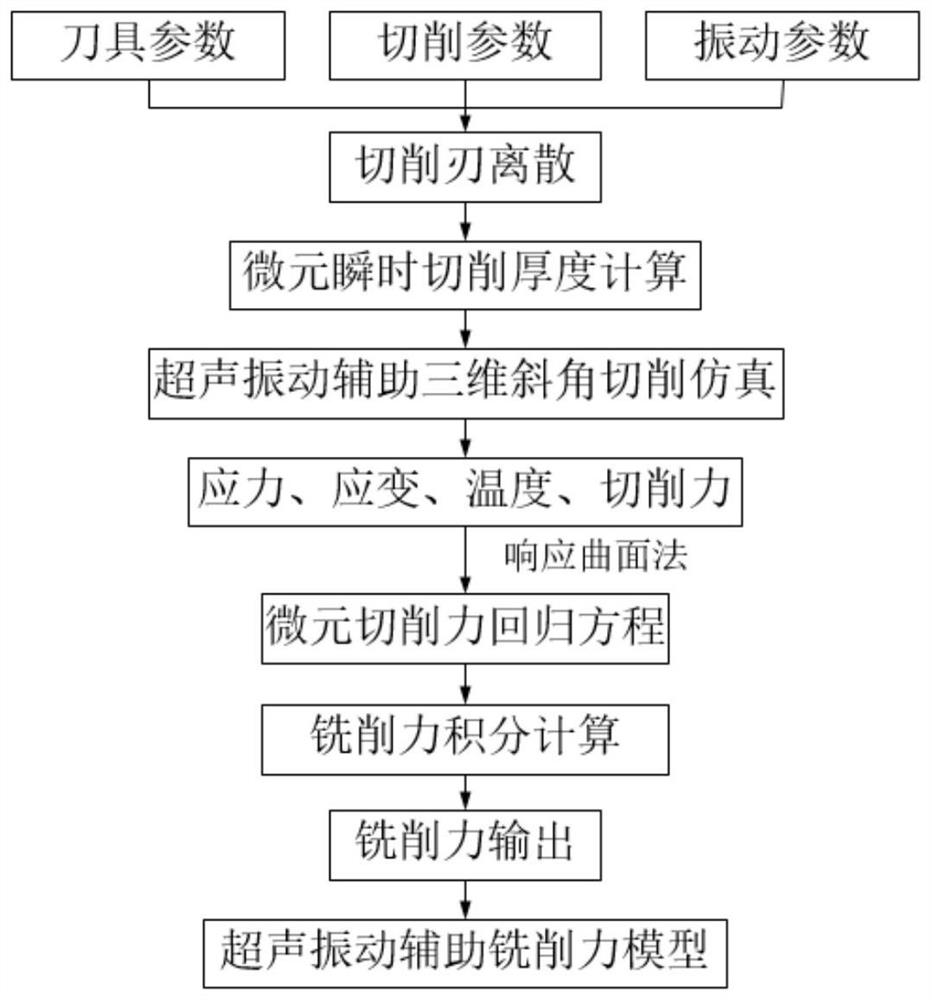

[0039] The technical route of the present invention is as figure 1 shown

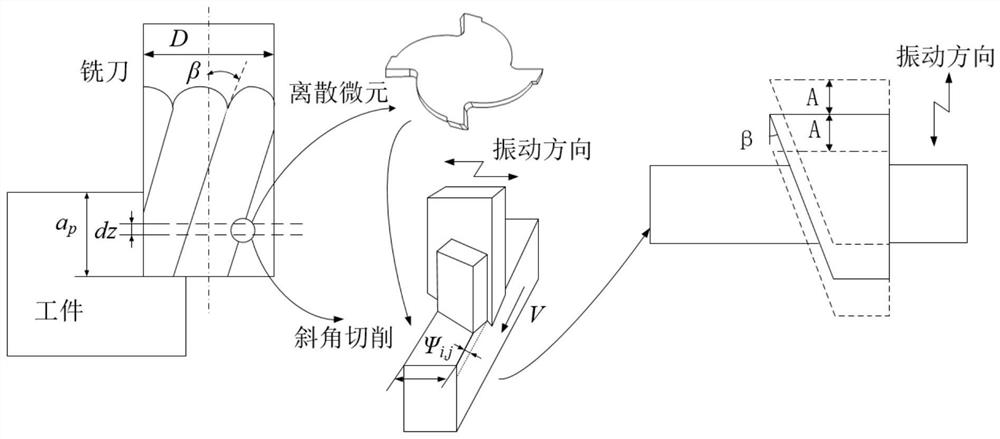

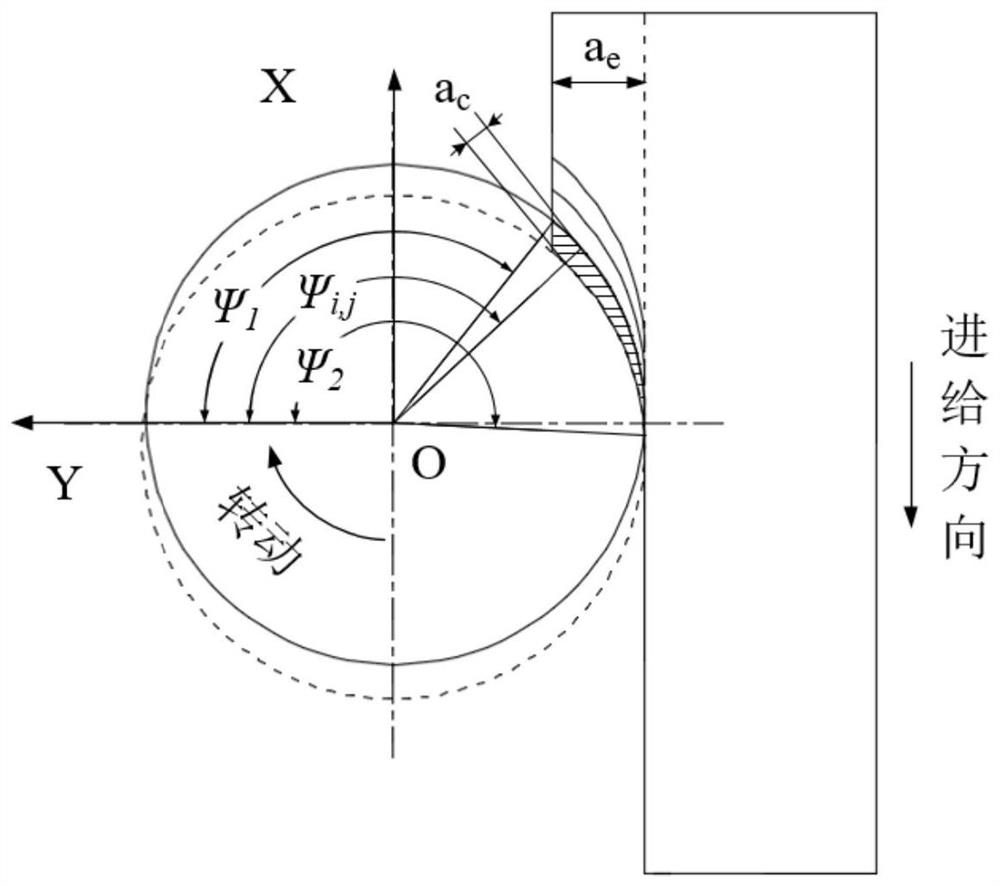

[0040] (1) First determine the parameters of the end mill: the tool radius R is 4mm, the helix angle β is 42°, the number of teeth of the milling cutter is 4; the milling method is down milling; cutting parameters: the spindle speed is 2000r / min, the feed per tooth 0.1mm / r, cutting depth 2mm, cutting width 3mm; ultrasonic vibration parameters: frequency 25000Hz, amplitude 4μm; workpiece material is Ti-6Al-4V. Such as figure 2 As shown, the tool coordinate system is established, the tool feed direction is +X, the direction perpendicular to the feed direction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com