Brushless motor and impeller thereof

A brushless motor and impeller technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve the effect of improving work efficiency, improving air separation state, and reducing air loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with each accompanying drawing.

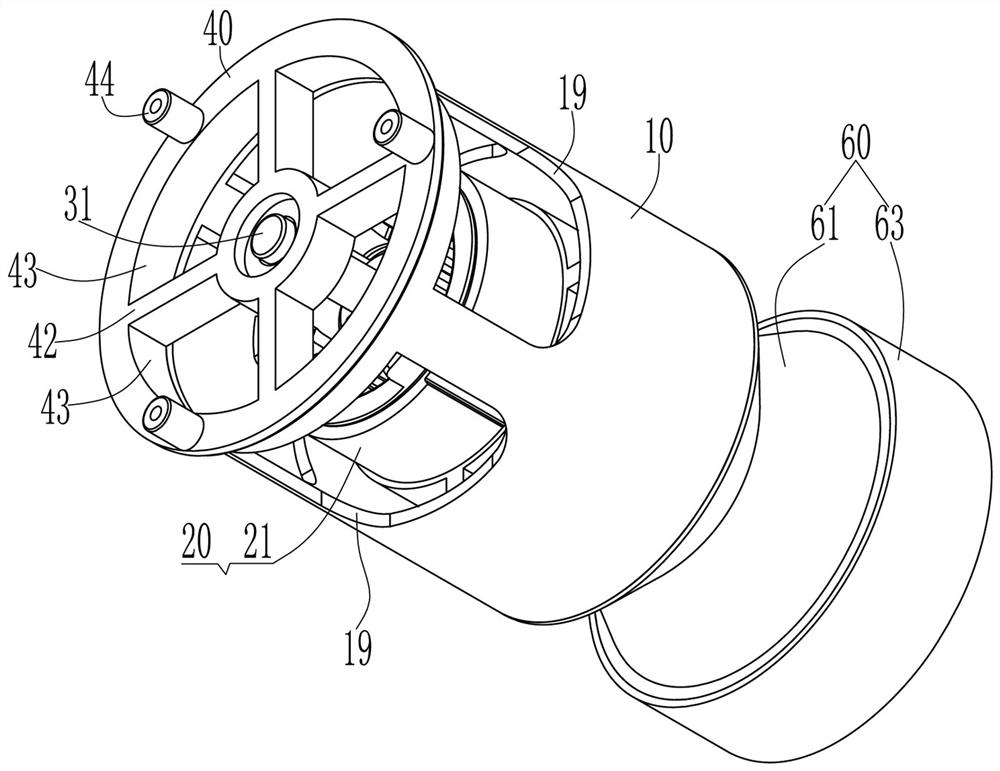

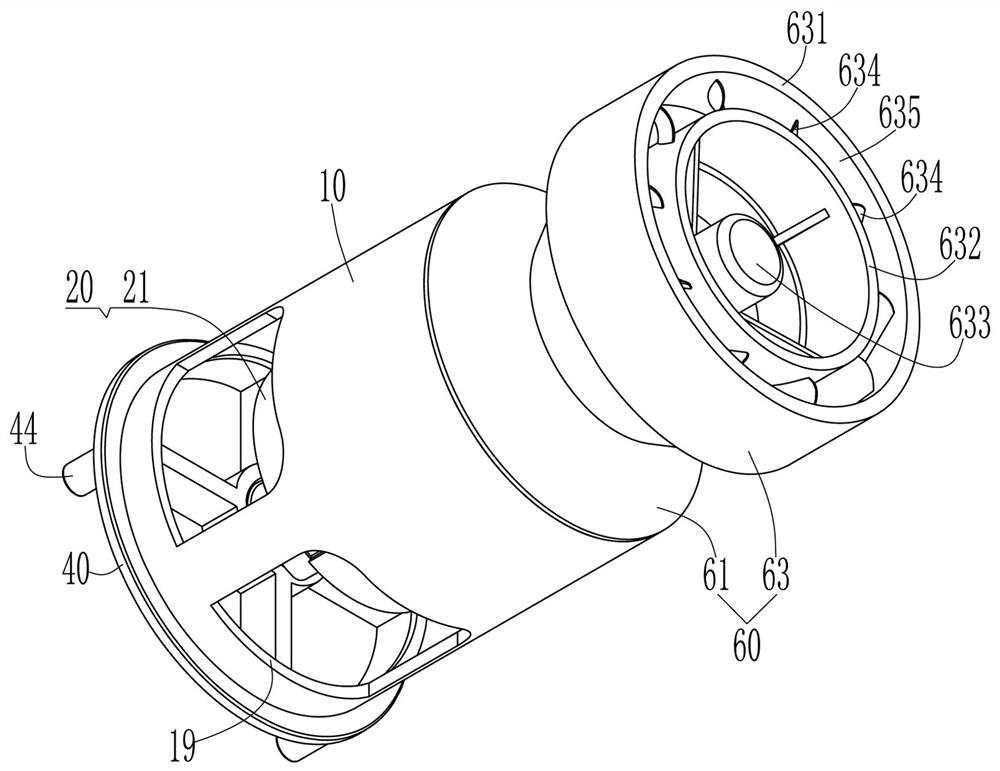

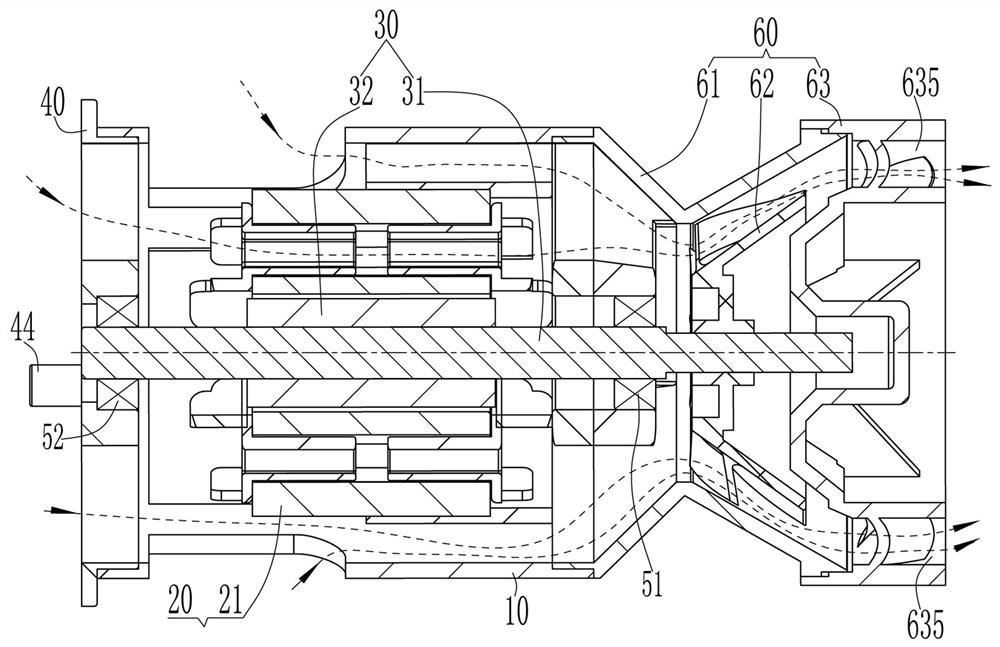

[0049] see Figure 1 to Figure 25 , a brushless motor, the brushless motor can be used in products such as vacuum cleaners, including a hollow housing 10 with openings at both ends, a stator assembly 20, a rotor assembly 30, a rear cover 40 with a rear bearing chamber 45, and a front bearing 51 and rear bearing 52; the stator assembly 20 includes a stator core 21 and a stator winding (not shown) arranged in each stator slot 211 of the stator core 21, for example, the applicant has a brushless motor using 3 The stator core 21 of a stator slot 211; the rotor assembly 30 includes a rotating shaft 31 and a permanent magnet part 32 fixed on the rotating shaft 31; the brushless motor also includes an air duct system component 60, and the air duct system component 60 includes a windshield 61 and an impeller 62 that are both open and hollow inside; the windshield 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com