Electric spark voltage-stabilizing power supply

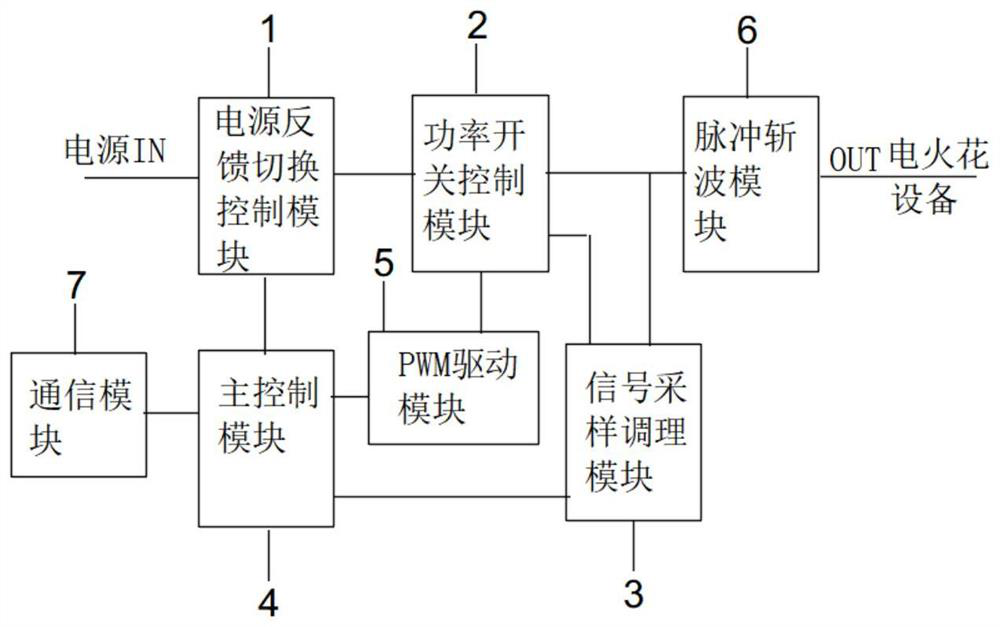

A technology of power supply and electric spark, applied in the direction of electrical components, adjusting electric variables, instruments, etc., can solve the problem that the power supply cannot meet the electricity demand of electric spark, affect the stability of electric spark power supply, power switch voltage and current surge, etc. problem, achieve the effect of ensuring stable switching and supply, simple structure, and suppressing the influence of pulse surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

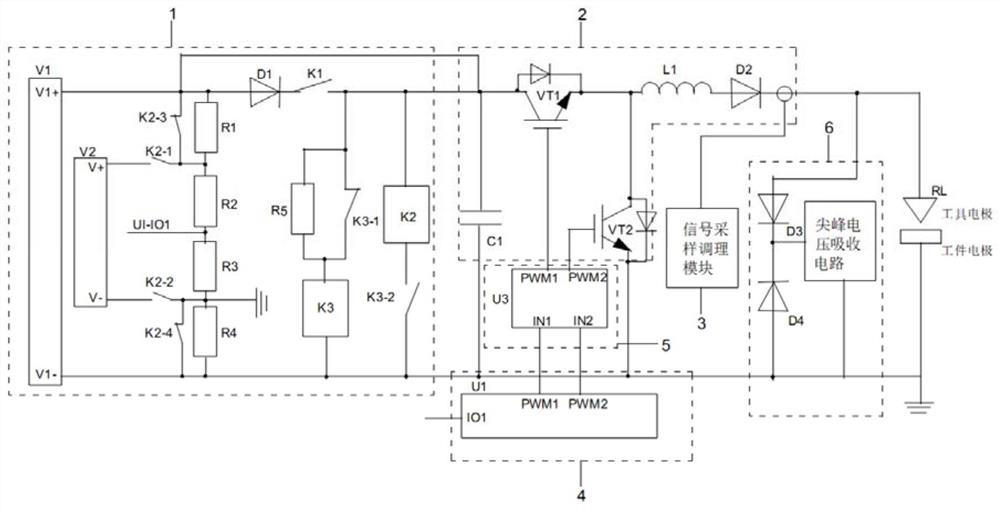

[0029] Embodiment 2: On the basis of Embodiment 1, please refer to figure 2 , in a specific embodiment of the electric spark stabilized power supply according to the present invention, the power feedback switching control module 1 includes a first power supply V1, a second power supply V2, a first resistor R1, and a fourth resistor R4 , the fifth resistor R5, the first diode D1, the first switch K1, the second relay K2, the third relay K3, the second switch K2-1, the third switch K2-2, the fourth switch K2-3, the Fifth switch K2-4, sixth switch K3-1 and seventh switch K3-2;

[0030] Specifically, the anode of the first power supply V1 is connected to the fourth switch K2-3, the first end of the first resistor R1, the anode of the first diode D1, the first switch K1, the sixth switch K3-1, the fifth Resistor R5 and second relay K2, the second end of the first resistor R1 is connected to the other end of the fourth switch K2-3 and connected to the positive pole of the second p...

Embodiment 3

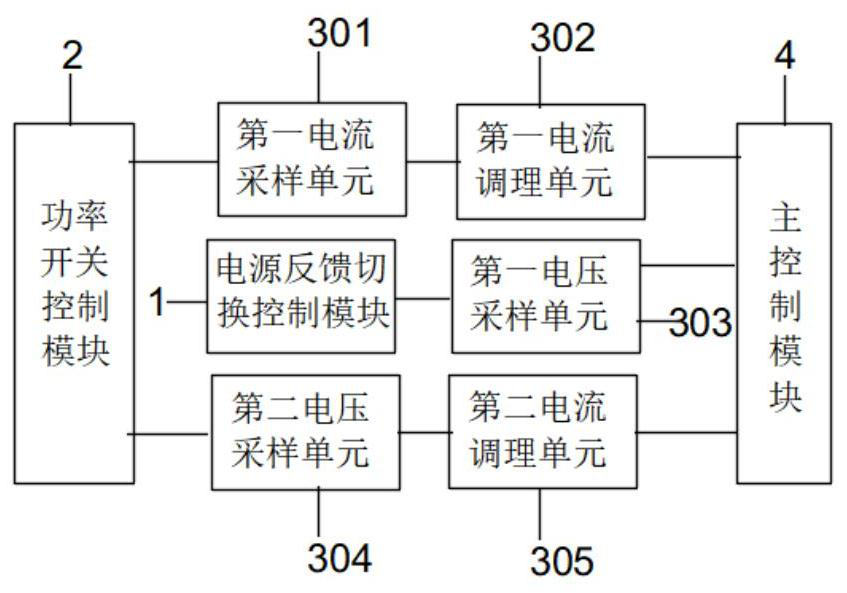

[0038] Embodiment 3: On the basis of Embodiment 1, please refer to figure 2 , image 3 , Figure 4 with Figure 5 , in a specific embodiment of the electric spark stabilized power supply described in the present invention, the signal sampling and conditioning module 3 includes a current signal sampling unit 301, a current signal conditioning unit 302, a first voltage signal sampling unit 303, a second A voltage signal sampling unit 304 and a second voltage signal conditioning unit 305;

[0039] Specifically, the current signal sampling unit 301 is configured to sample the current signal output by the power switch control module 2;

[0040] A current signal conditioning unit 302, configured to perform voltage conversion, voltage follow and voltage bias processing on the sampled current signal;

[0041] The first voltage signal sampling unit 303 is configured to sample the power supply in the power supply feedback switching control module 1;

[0042] The second voltage sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com