Novel capillary tube cooling net

A technology of capillary tubes and cooling nets, which is applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., and can solve problems such as low system energy usage, low temperature of waste water, and difficulty in recycling , to achieve the effect of improving energy utilization rate, small hydraulic loss and thin heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

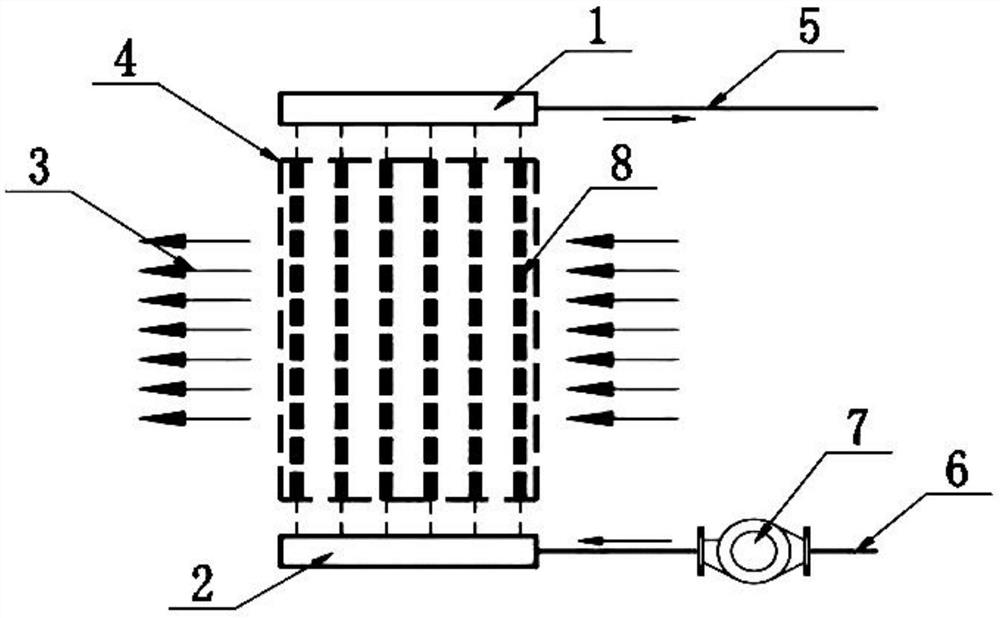

[0017] Please refer to the drawings of the description, in the embodiment of the present invention, a new type of capillary cooling network, which includes a steam collector 1, a liquid separator 2, multiple cooling networks, a refrigerant working medium 6 and a server cabinet 4;

[0018] Steam collector 1: collect the steam working medium in the capillary for the next step utilization of the steam working medium in the whole system;

[0019] Liquid separator 2: distribute the refrigerant working medium evenly in each capillary 8;

[0020] Air-cooling equipment 3: Collect the heat dissipated from the mainboard of the server for subsequent use of waste heat;

[0021] Server cabinet 4: the back panel, top panel, side panel and other cooling net attachment parts of the cabinet;

[0022] Working medium pump 7: provide 6 low-temperature liquid refrigerant circulating power;

[0023] Capillary 8: During the entire cooling process, the capillary is also the evaporator of the refrig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap