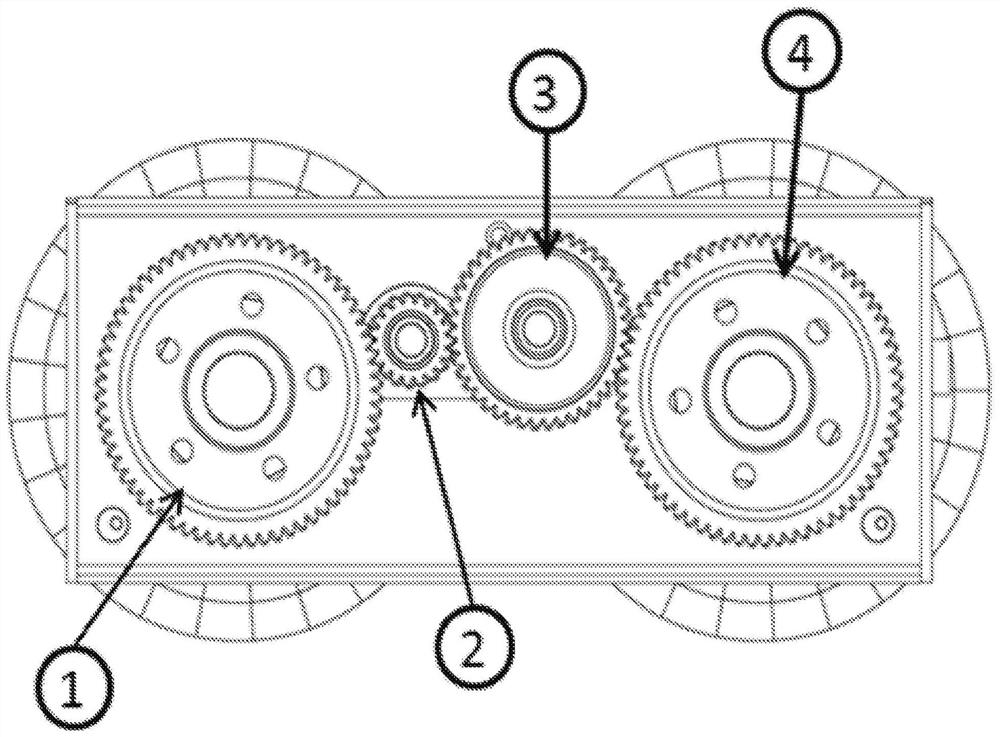

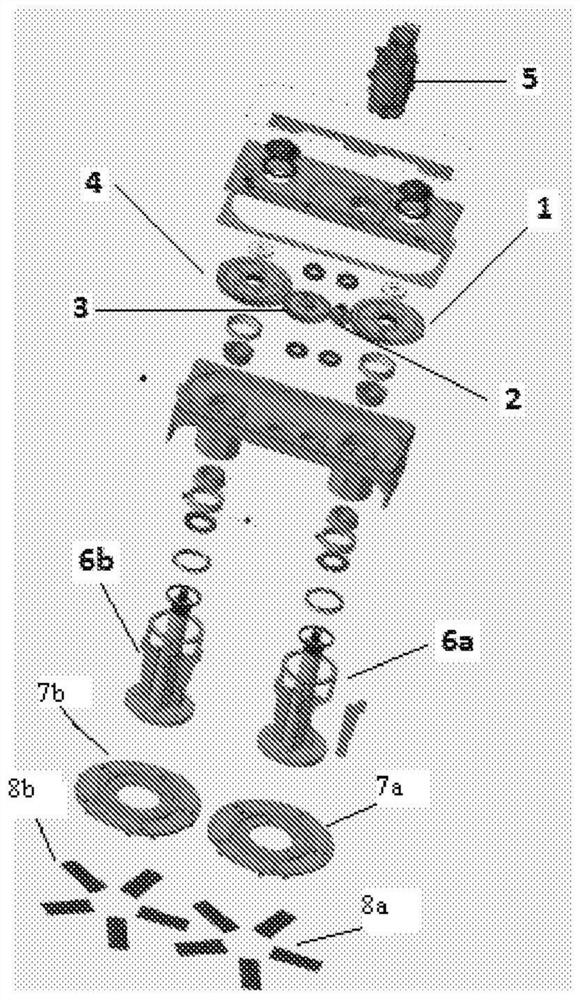

A sugarcane harvester with improved basecutter gearbox assembly

A technology of cutters and gearboxes, applied in harvesters, chassis of agricultural machinery, agricultural machinery and implements, etc., can solve capital increase maintenance, downtime and waste disposal costs, too much noise and vibration of root cutter gearboxes , Improper balance of rotating parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Before the present invention is described in detail, it is to be understood that the invention is not limited in application to the details of construction and arrangement of parts shown in the drawings. The invention is capable of other embodiments depicted in figures than those described above, and of being practiced or carried out in various ways. It is to be understood that the phraseology and terminology employed herein are for the purpose of description rather than limitation.

[0019] Harvesting is an important part of the sugarcane production system. Harvesting sugarcane by hand requires farmers to manually cut the cane stalks with machetes or knives, so cane harvesters often feel tired after hours of work and need frequent breaks. Harvesting sugar cane manually can cause muscle and joint damage. Mechanical harvesters alleviate the strenuous physical activity and dangers associated with manual harvesting. Sugar cane harvester prepares a large amount of sugar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com