Beef cattle ecological breeding pasture simulating grazing environment

A technology of ecological breeding and beef cattle, which is applied in the field of beef cattle ecological breeding and pastures, can solve the problems of ecological damage and difficult management, and achieve the effect of ensuring cleanliness and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

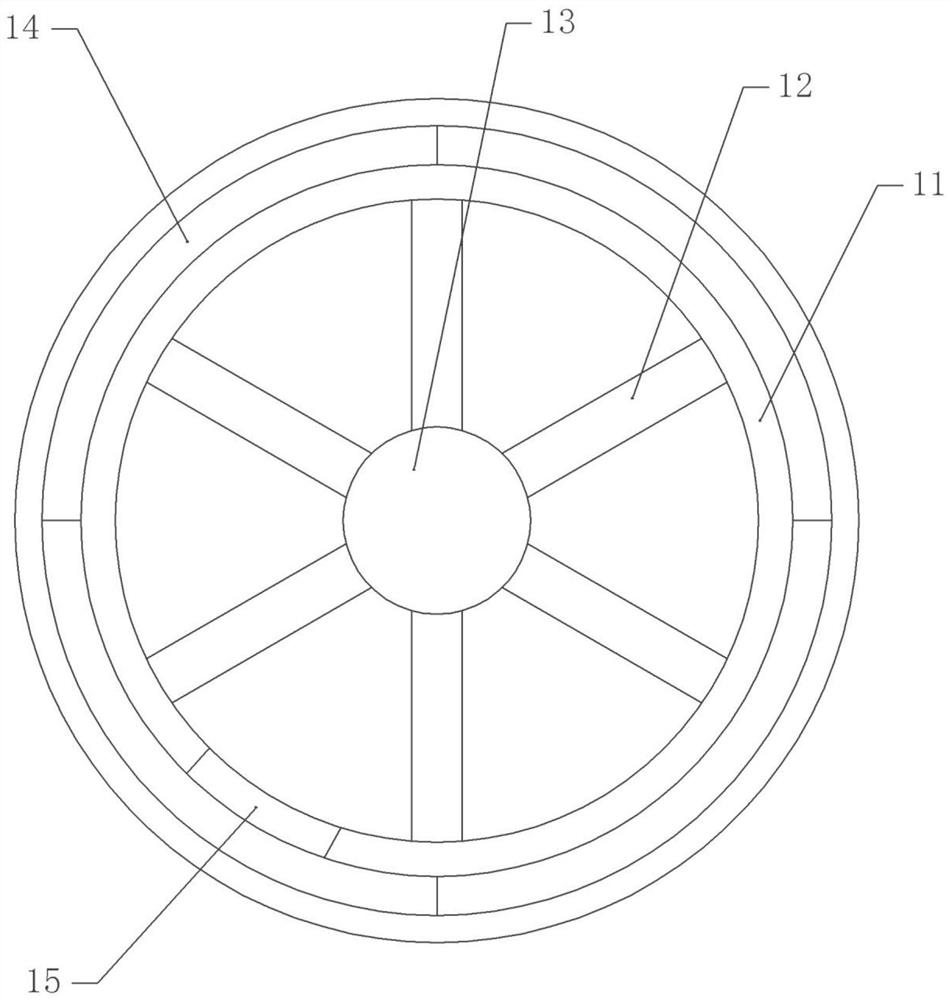

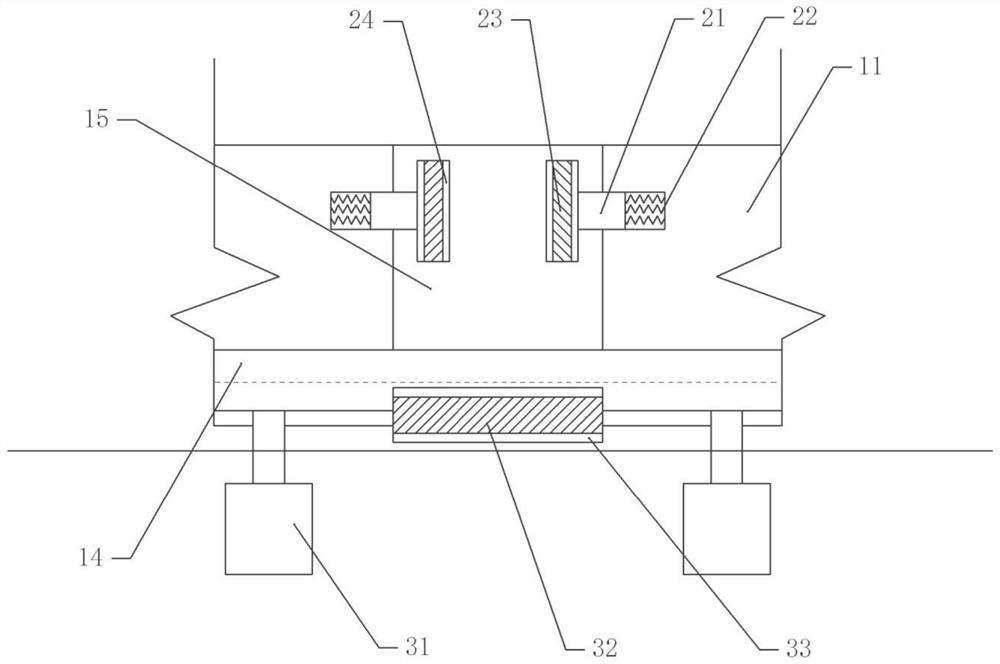

[0039] Basic as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 Shown: a beef cattle ecological breeding pasture simulating a grazing environment, including an outer ring fence and an inner ring fence 11 located in the outer ring fence, and a septic tank 41 pre-buried under the ground is arranged below the inner ring fence 11 .

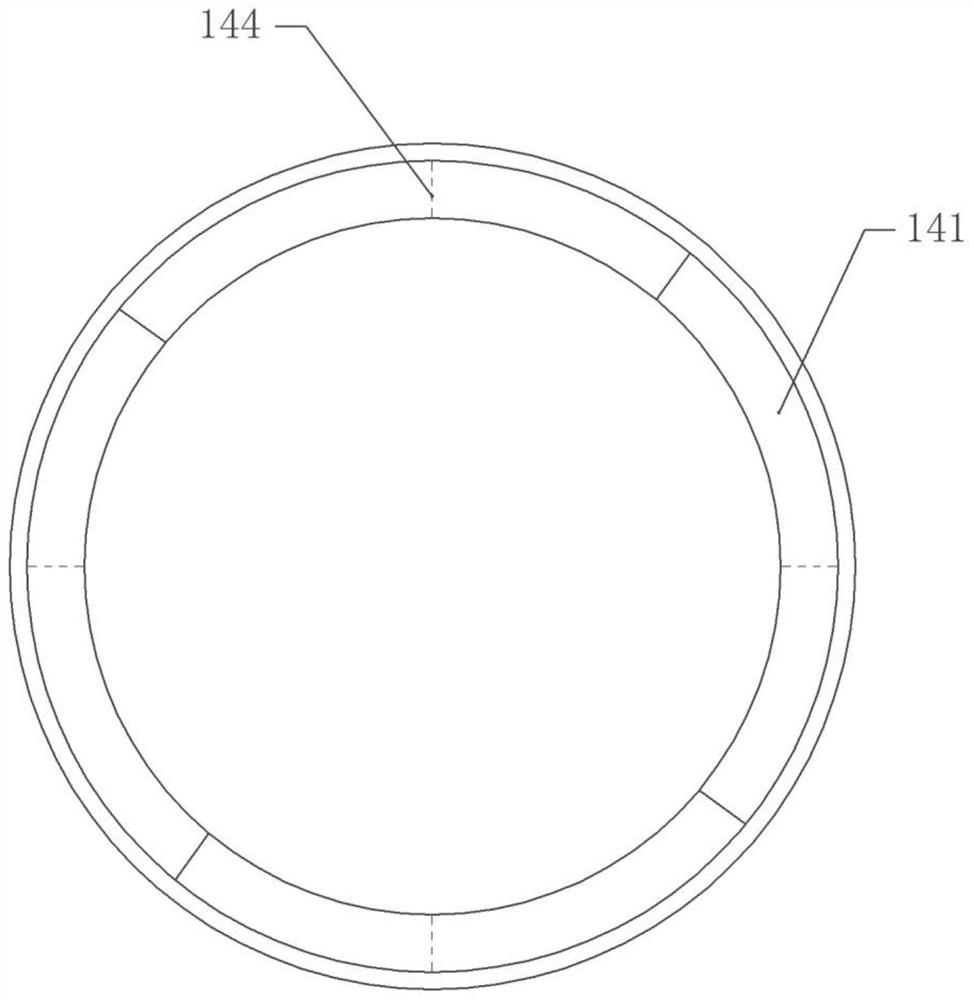

[0040] In this embodiment, several power parts are arranged below the outer ring fence (the power parts can be pre-buried under the ground), and the power parts are evenly distributed along the circumference of the outer ring fence. The fence is fixedly connected. The outer ring fence is provided with a feeding area 14, and some transmission mechanisms are arranged in the feeding area 14. The transmission mechanism is an arc-shaped conveyor belt 144, and an arc-shaped feeding plate 141 is arranged above the conveyor belt 144. The two ends of 141 are fixedly installed on two adjacent conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com