Preparation method of uniform spherical submicron-grade barium titanate powder

A barium titanate powder, sub-micron technology, applied in fixed capacitor parts, electrical components, fixed capacitor dielectric, etc., can solve the problems of increased production costs, coarse product particles, large equipment investment, etc., to achieve energy consumption Low cost, simple process flow and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Measure lye ammonium hydroxide solution (25-28%) and titanium solution titanium tetrachloride solution respectively, slowly drop 20mL titanium tetrachloride solution into 200mL deionized water under stirring state, and leave it to age for 30min , take 60mL of ammonium hydroxide solution and slowly titrate and neutralize until a large amount of precipitates are precipitated, and then wash, filter and dry to obtain α-titanic acid.

[0032] Using the α-titanic acid obtained above as a raw material, weigh barium hydroxide and α-titanic acid respectively according to the barium-titanium molar ratio of 1.05:1, mix the two together and pour them into a ball mill jar, place them on the jar mill at a speed of 600r / min After grinding for 7 hours, the material was taken out and put into an alumina crucible, then dried in an oven at 120°C for 4 hours and then cooled to room temperature to obtain a barium titanate sample powder.

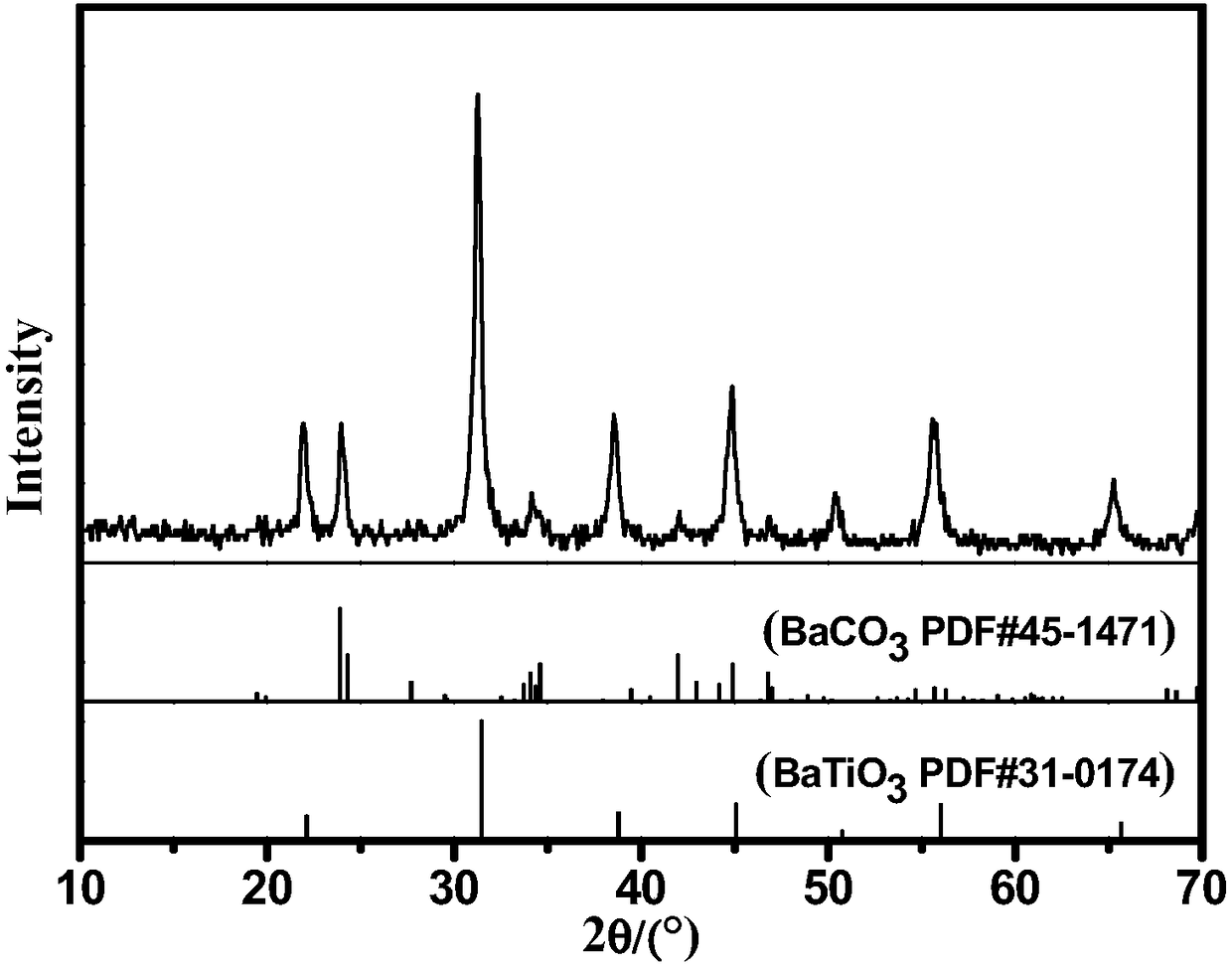

[0033] see figure 1 , analyzed by X-ray diffractome...

Embodiment 2

[0035] Measure lye ammonium hydroxide solution (25-28%) and titanium solution titanium tetrachloride solution respectively, slowly drop 20mL titanium tetrachloride solution into 200mL deionized water under stirring state, and leave it to age for 30min , take 60mL of ammonium hydroxide solution and slowly titrate and neutralize until a large amount of precipitates are precipitated, and then wash, filter and dry to obtain α-titanic acid.

[0036] Using the α-titanic acid obtained above as a raw material, weigh barium hydroxide and α-titanic acid respectively according to the barium-titanium molar ratio of 1:1.1, mix them together and pour them into a ball mill jar, place them on the jar mill at a speed of 800r / min After grinding for 5 hours, the material was taken out and put into an alumina crucible, then dried in an oven at 180°C for 2 hours and then cooled to room temperature to obtain a barium titanate sample powder.

[0037] see Figure 4 , analyzed by X-ray diffractometer...

Embodiment 3

[0039] Measure lye ammonium hydroxide solution (25-28%) and titanium solution titanium tetrachloride solution respectively, slowly drop 20mL titanium tetrachloride solution into 200mL deionized water under stirring state, and leave it to age for 30min , take 60mL of ammonium hydroxide solution and slowly titrate and neutralize until a large amount of precipitates are precipitated, and then wash, filter and dry to obtain α-titanic acid.

[0040] Use the α-titanic acid obtained above as a raw material, weigh barium hydroxide and α-titanic acid respectively according to the barium-titanium molar ratio of 0.92:1, mix the two together and pour them into a ball mill jar, place them on the jar mill at a speed of 1000r / min After grinding for 3 hours, the material was taken out and put into an alumina crucible, then dried in an oven at 80°C for 6 hours and then cooled to room temperature to obtain a barium titanate sample powder.

[0041] see Image 6 , analyzed by X-ray diffractomete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com