Integrated feeding device for storage and feeding

A feeding device and material storage technology, which is used in transportation and packaging, packaging, fish farming, etc., can solve the problems of insufficient and limited feed mixing, and the range of centralized feeding of blanking materials, and achieve the effect of improving the level of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

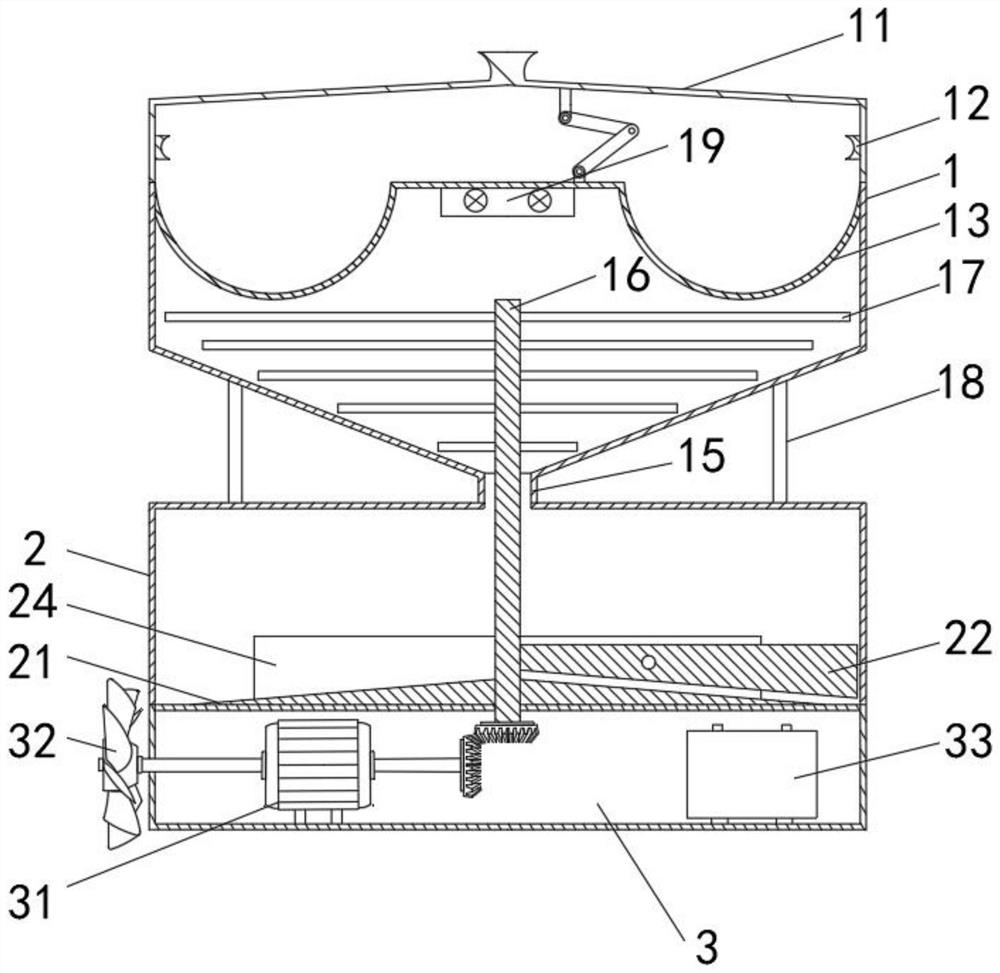

[0036] See attached manual Figure 1-2 , 5, the integrated feeding device for storage and feeding, including:

[0037] Storage device 1, the storage device 1 has a cylindrical structure, the inner diameter of the bottom of the storage device 1 is reduced and is provided with a material transfer port 15, and a material storage guide plate 13 is provided at the feeding port at the upper end of the storage device 1, and the material storage guide plate 13 The side is connected with the inner wall of the storage device 1;

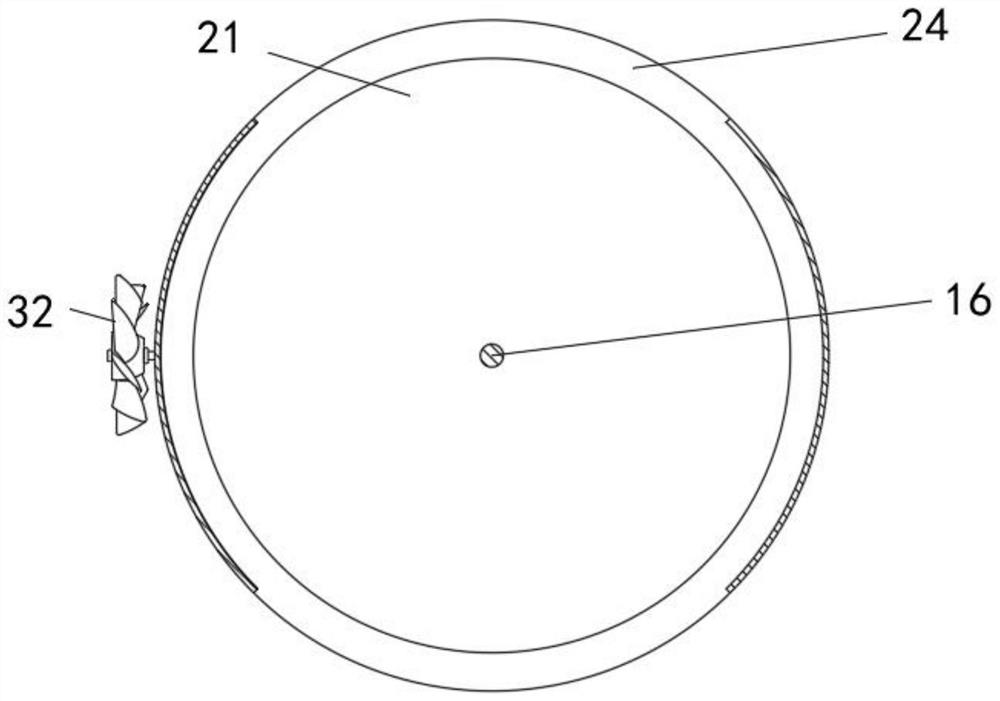

[0038] Feeding device 2, the feeding device 2 is located at the bottom of the feeding device 1, the feeding device 2 is a cylindrical structure, the bottom of the side wall of the feeding device 2 is provided with a discharge port 24, and the upper part of the feeding device 2 passes through the pipe body and the bottom of the feeding device 1. The feeding port 15 is connected to the feeding device 2, and the feeding device 2 is provided with a rotating shaft ...

Embodiment 2

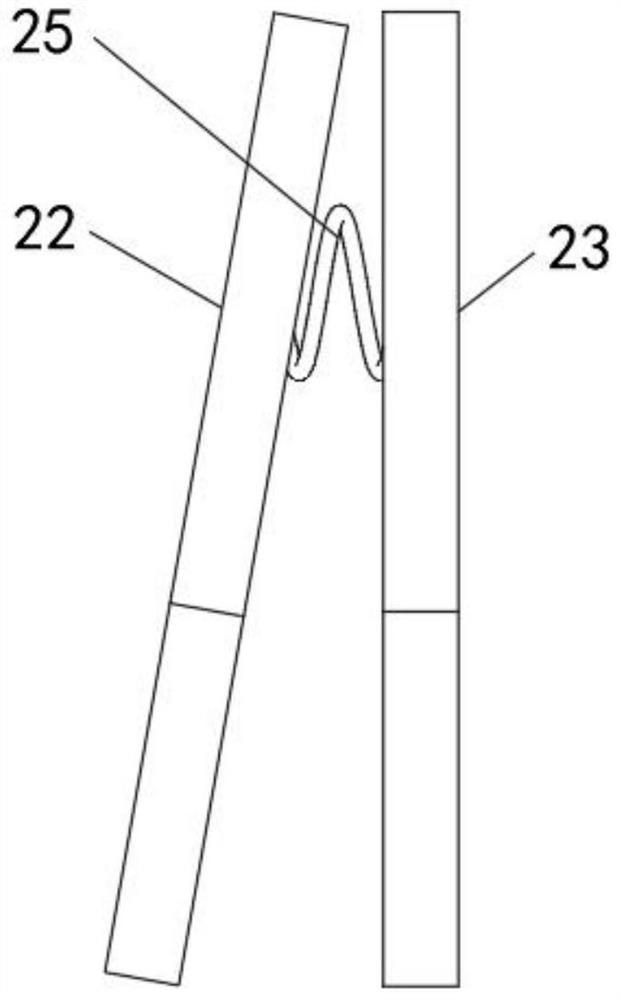

[0055] like figure 1 The shown integrated feeding device for feeding and feeding can be used to store the material in the storage device 1 on the shore in advance. The stirring rod 17 below the storage guide plate 13 stirs evenly, and then the entire feeding device can be driven by the propeller 32 to the area to be fed. The centrifugal force and elastic force when the feeding plate 22 and the second feeding plate 23 rotate, and the gravity when the feed slides down, throw the feed out of the feeding port 24 .

Embodiment 3

[0057] This embodiment is further optimized on the basis of Embodiment 1 as follows: refer to the appendix of the description Figure 7 As shown, the integrated feeding device for storing and feeding can also be connected by a hinged rod group 4 of a rhombus hinged structure. The connection of each feeding device can be realized through the hinged rod group 4, which is beneficial for each feeding device to effectively resist wind and waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com