Goat yoghurt with strong milk coagulation performance and preparation method of goat yoghurt

A technology of goat yogurt and goat acid, applied in dairy products, other dairy products, milk preparations, etc., can solve problems such as inability to obtain goat yogurt with consistent quality, difficulty in obtaining easy-to-drink products, and inability to guarantee large-scale supply all year round , to achieve the effect of good overall sensory quality, low production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

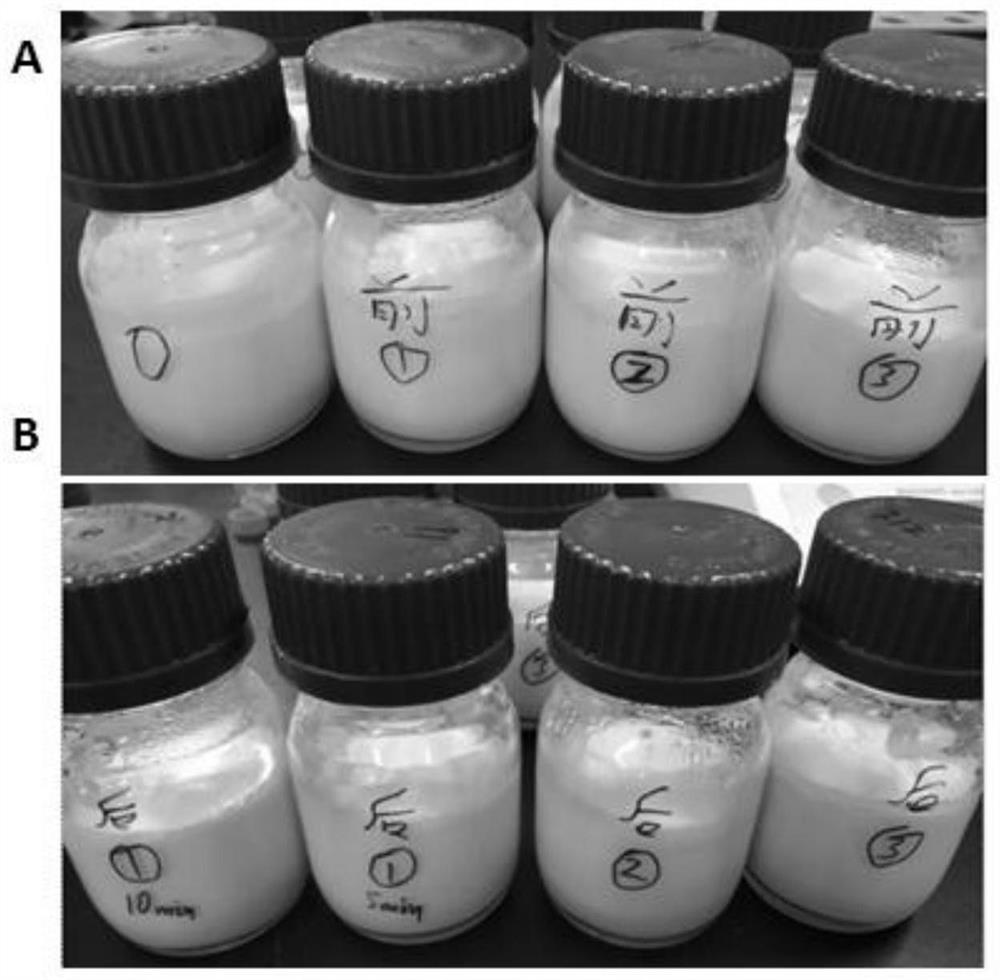

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing goat yoghurt with strong curdling performance, which specifically includes the following steps:

[0032] S1, mix 17g of skimmed goat milk powder and 7g of white sugar into 100g of sterile water heated to 65°C, and stir at a speed of 850 rpm for 5 minutes to obtain reconstituted milk, then cool the reconstituted milk to 40°C with flowing water At -45°C, add 0.5g of yogurt starter and stir evenly to obtain a mixed emulsion;

[0033] S2, placing the mixed emulsion in an ultrasonic cell disruption device, and ultrasonically treating it at room temperature for 10 minutes at an ultrasonic frequency of 20KHz and an ultrasonic power of 550W;

[0034] S3, immediately bottling and sealing the ultrasonically treated mixed emulsion, and cooling to 43° C. with flowing water;

[0035] S4, then place the mixed emulsion in an incubator at 44°C for 6.5 hours, then transfer to 4°C and ferment for 24 hours to obtain goat yogurt with good cu...

Embodiment 2

[0038] This embodiment provides a method for preparing goat yoghurt with strong curdling performance, which specifically includes the following steps:

[0039] S1, mix 16g of skimmed goat milk powder and 6g of white sugar into 95g of sterile water heated to 60°C, and stir at a speed of 700 rpm for 5 minutes to obtain reconstituted milk, then use running water to cool the reconstituted milk to 40°C At ℃, add 0.4g yogurt starter, stir evenly, and obtain mixed emulsion;

[0040] S2, placing the mixed emulsion in an ultrasonic cell disruption device, and ultrasonically treating it at room temperature for 10 minutes at an ultrasonic frequency of 20KHz and an ultrasonic power of 500W;

[0041] S3, immediately bottling and sealing the mixed emulsion after the ultrasonic treatment, and cooling it to 40° C. with flowing water;

[0042] S4, then place the mixed emulsion in an incubator at 43°C for 6 hours, then transfer to 4°C and ferment for 24 hours, then you can get goat yogurt with...

Embodiment 3

[0044] This embodiment provides a method for preparing goat yoghurt with strong curdling performance, which specifically includes the following steps:

[0045] S1, mix 18g of skimmed goat milk powder and 8g of white sugar into 105g of sterile water heated to 70°C, and stir at a speed of 1000 rpm for 5 minutes to obtain reconstituted milk, then use running water to cool the reconstituted milk to 45 ℃, add 0.6g of yogurt starter, stir evenly, and obtain a mixed emulsion;

[0046] S2, placing the mixed emulsion in an ultrasonic cell disruption device, and ultrasonically treating it at room temperature for 10 minutes at an ultrasonic frequency of 20KHz and an ultrasonic power of 600W;

[0047] S3, immediately bottling and sealing the ultrasonically treated mixed emulsion, and cooling to 45° C. with flowing water;

[0048] S4, then place the mixed emulsion in an incubator at 45°C for 8 hours, then transfer to 4°C and ferment for 24 hours to obtain yogurt with good curdling state, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com