Coiling method for producing ultra-thin strip steel from ferrite on basis of hot continuous rolling mill

A technology of hot continuous rolling mill and ultra-thin strip, which is applied in metal rolling, metal rolling, manufacturing tools, etc. It can solve the problem that the coiling temperature is difficult to reach the coiling target temperature, so as to save part of the cold rolling process and expand Product specifications and the effect of improving moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

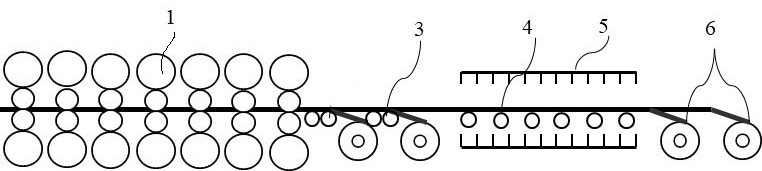

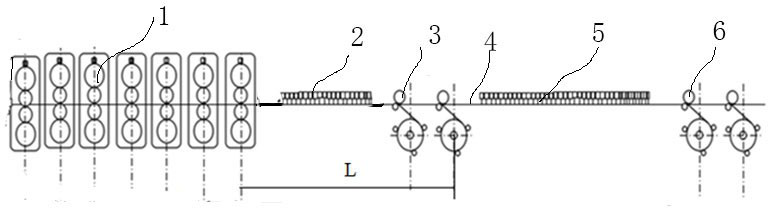

[0021] The strip hot continuous rolling production line in this embodiment is a traditional production line, including a roughing mill, a heat preservation cover, intermediate billet cooling, a cropping shear, fine descaling and a finishing rolling unit 1, with a slab thickness of 150-250 mm, and a finishing rolling unit 1 1 between the outlet end and the normal distance coiler 6 is provided with a heat output roller table 4, that is, one end of the heat output roller table 4 is connected to the outlet end of the finishing rolling unit 1, and the other end is connected to the normal distance coiler 6, and the heat output The output roller table 4 has a length of more than 100 meters. The applicant's repeated experiments have shown that when the hot-rolled strip steel with extremely thin specifications (1.2mm≤thickness≤2.3mm) is produced on this production line, because the hot output roller table is too long, it is normal for the strip steel to reach the end of the hot output r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com