Semi-automatic pressing tool based on automotive electronics industry

A semi-automated, automotive electronics technology, applied in metal processing, manufacturing tools, vehicle parts, etc., can solve the problems of semi-automatic pressing tooling, such as large area, high cost, and large number of tooling fixtures, to increase per capita output value , Reduce labor intensity and reduce the effect of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

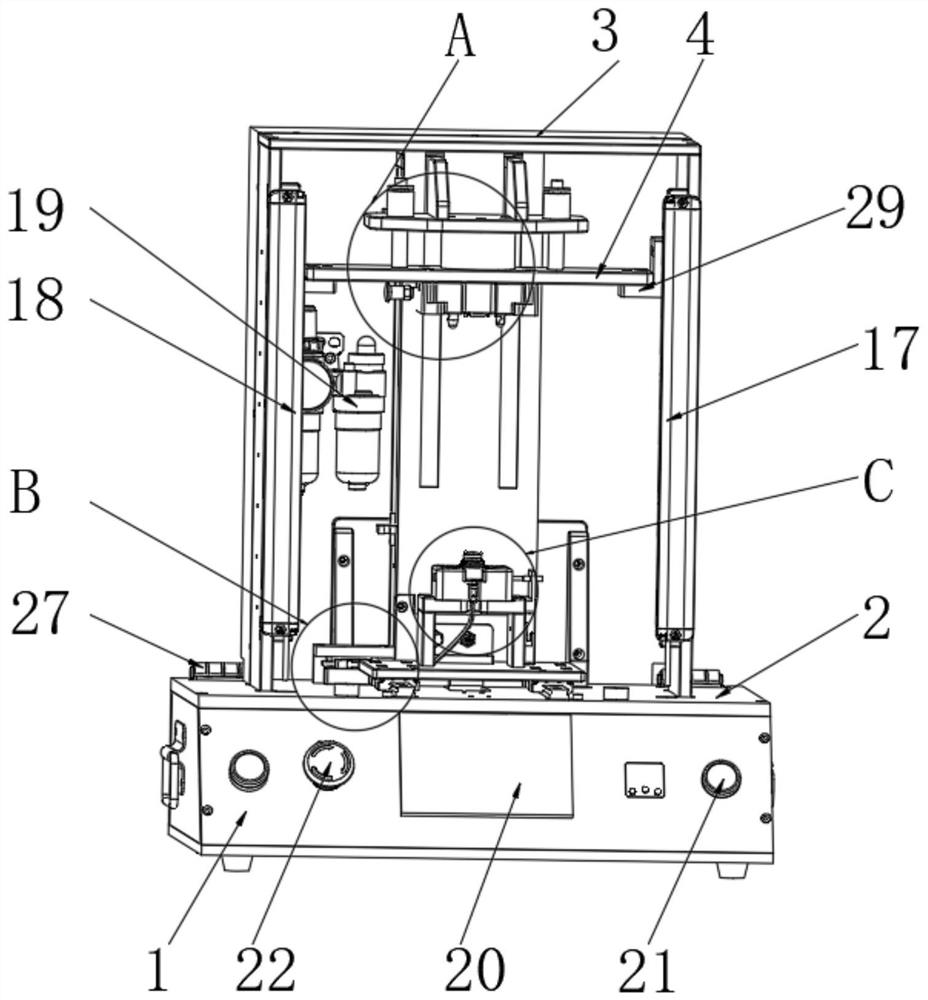

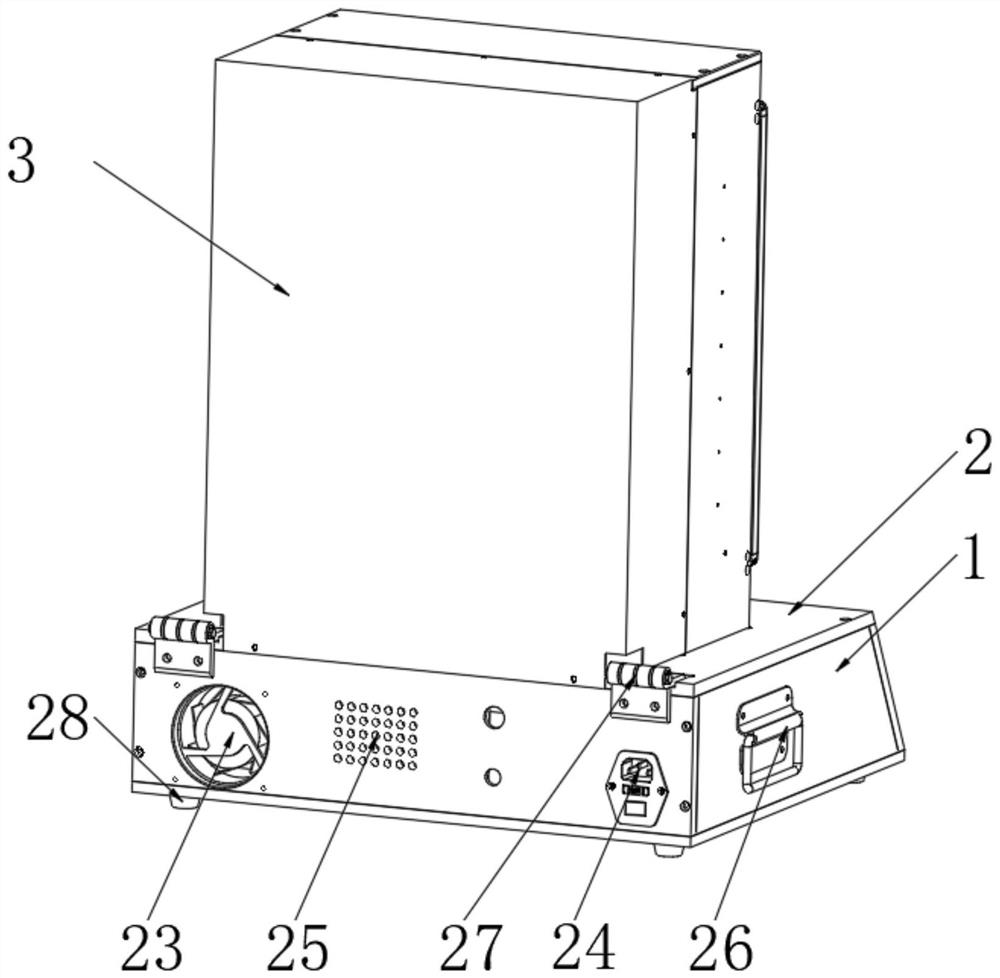

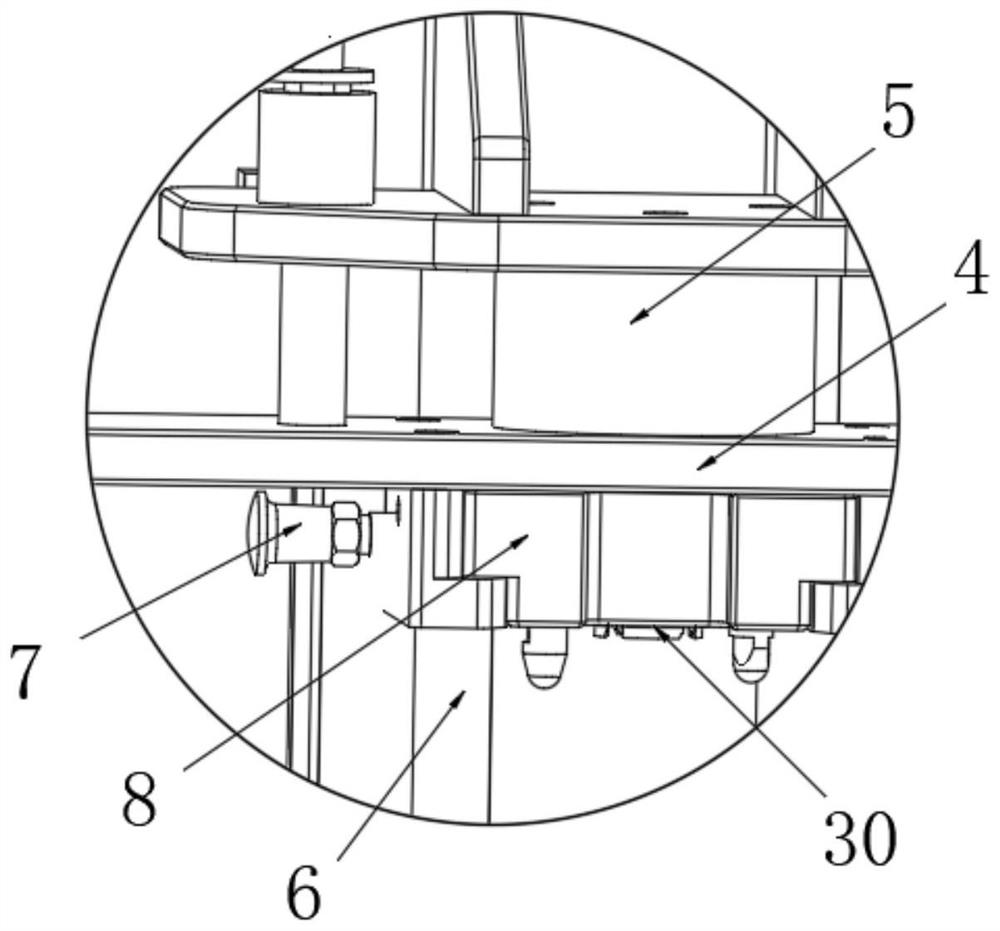

[0039] The following is attached figure 1 -7 further elaborate on the present invention.

[0040] see figure 1 -4. The present invention provides a technical solution: a semi-automatic pressing tool based on the automotive electronics industry, such as figure 1 with image 3 As shown, it includes a control box base 1, the upper surface of the control box base 1 is fixedly connected with a mounting plate 2, the upper surface of the mounting plate 2 is provided with a mounting box 3, and the upper surface of the mounting plate 2 is provided with a guide rail A translation auxiliary assembly, the top of the guide rail translation auxiliary mechanism is provided with a lower mold assembly, the inner top of the installation box 3 is provided with a Z-axis pressing assembly, and both sides of the installation box 3 are provided with a grating assembly. The Z-axis pressing assembly includes two L-shaped connecting plates 29, the two L-shaped connecting plates 29 are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com