Metal glass composite material with wave structure

A technology of wave structure and metallic glass, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of limited application range, inability to prepare wave structures, limited forming ability of metallic glass, etc., and achieve powerful Effects of fatigue resistance, span improvement, and superior energy-absorbing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

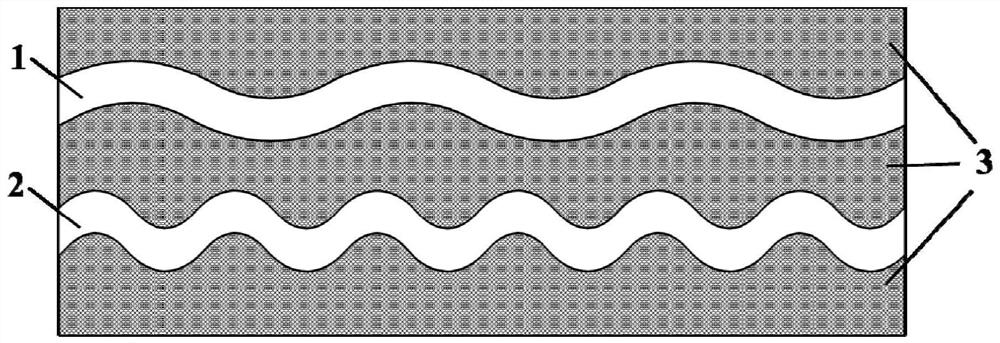

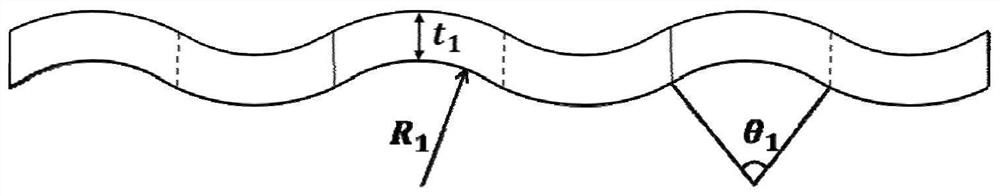

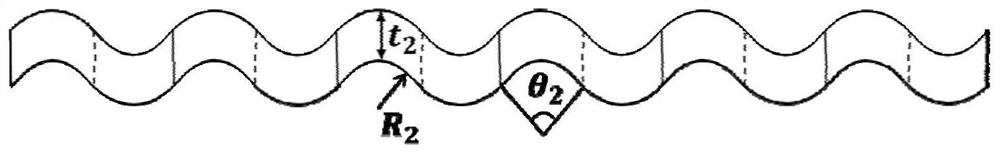

[0024] see figure 1 , the present invention includes a reinforcement phase and a substrate 3, the reinforcement phase is two kinds of corrugated structures, respectively the first metallic glass corrugated structure 1 and the second metallic glass corrugated structure 2, and the substrate 3 is filled in the first metallic glass corrugated structure 1 and between and around the second metallic glass wave structure 2 . The first metallic glass corrugated structure 1 and the second metallic glass corrugated structure 2 are metallic glass, and the substrate 3 is made of high molecular polymer, porous material or common metal. Both the first metallic glass wave structure 1 and the second metallic glass wave structure 2 are composed of a number of units of the same size and shape that are periodically arranged. The first metallic glass wave structure 1 and the second metall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap