Tailing-based artificial garden soil and preparation method thereof

An artificial and garden technology, applied in the field of solid waste resource utilization and ecological restoration, can solve problems such as the shortage of high-quality soil resources for tailings, and achieve the effects of solving the shortage of high-quality soil, low cost of raw materials, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

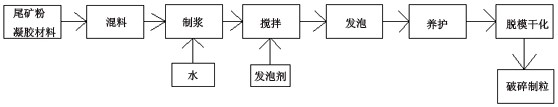

Method used

Image

Examples

Embodiment 1

[0030] The raw materials and formula of this embodiment are: 96% of tailings powder under 100 mesh sieve, 4% of ordinary silicon 42.5 cement, 0.1% of aluminum powder, and water-cement ratio of 0.62. The preparation process is as follows: firstly grind the tailings raw materials to a 100-mesh sieve, then quantitatively weigh 960g of tailings powder, 40g of ordinary silicon 42.5 cement, 1g of aluminum powder, and 620g of tap water; Add it into the mixing tank and stir for 5 minutes at a speed of 800 rpm; then add a foaming agent and continue stirring for 30 seconds at a stirring speed of 1200 rpm; then quickly pour the slurry into a 100×100×200 mm In the steel mold, stop foaming for 30 minutes; put the foam and the mold together in the curing box for curing, the curing temperature is 50 ° C, and the curing time is 20 hours; take out the foam and the mold from the oven, and The foam block is removed from the mold and baked in an oven at 105°C for 20 hours; then the dried foam is ...

Embodiment 2

[0032] The raw materials and formula of this embodiment are: 93% of tailings powder under 100 mesh sieve, 7% of ordinary silicon 42.5 cement, 0.3% of aluminum powder, and water-cement ratio of 0.7. The preparation process is as follows: firstly grind the tailings raw materials to a 100-mesh sieve, then quantitatively weigh 930g of tailings powder, 70g of ordinary silicon 42.5 cement, 3g of aluminum powder, and 700g of tap water; Add it into the mixing tank and stir for 5 minutes at a speed of 800 rpm; then add a foaming agent and continue stirring for 30 seconds at a stirring speed of 1200 rpm; then quickly pour the slurry into a 100×100×200 mm In the steel mold, stop foaming for 30 minutes; put the foam and the mold together in the curing box for curing, the curing temperature is 40 ° C, and the curing time is 25 hours; take out the foam and the mold from the oven, and The foam block is removed from the mold and baked in an oven at 105°C for 30 hours; then the dried foam is p...

Embodiment 3

[0034] The raw materials and formula of this embodiment are: 90% of tailings powder under 100 mesh sieve, 10% of ordinary silicon 42.5 cement, 0.3% of aluminum powder, and water-cement ratio of 0.7. The preparation process is as follows: firstly grind the tailings raw materials to a 100-mesh sieve, then quantitatively weigh 900g of tailings powder, 100g of ordinary silicon 42.5 cement, 3g of aluminum powder, and 700g of tap water; Add it into the mixing tank and stir for 5 minutes at a speed of 800 rpm; then add a foaming agent and continue stirring for 30 seconds at a stirring speed of 1200 rpm; then quickly pour the slurry into a 100×100×200 mm In the steel mold, stop foaming for 30 minutes; put the foam and the mold together into the curing box for curing, the curing temperature is 50 ° C, and the curing time is 15 hours; take out the foam and the mold from the oven, and The foam block is removed from the mold and baked in an oven at 105°C for 20 hours; then the dried foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com