A pre-processing device for identifying the quality of hot pot fat

A grease and quality technology, which is applied in the field of pre-treatment devices for identifying the quality of hot pot grease, can solve the problems of complex process flow and large amount of manual operation, and achieve the effects of uniform heating, reduced workload, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

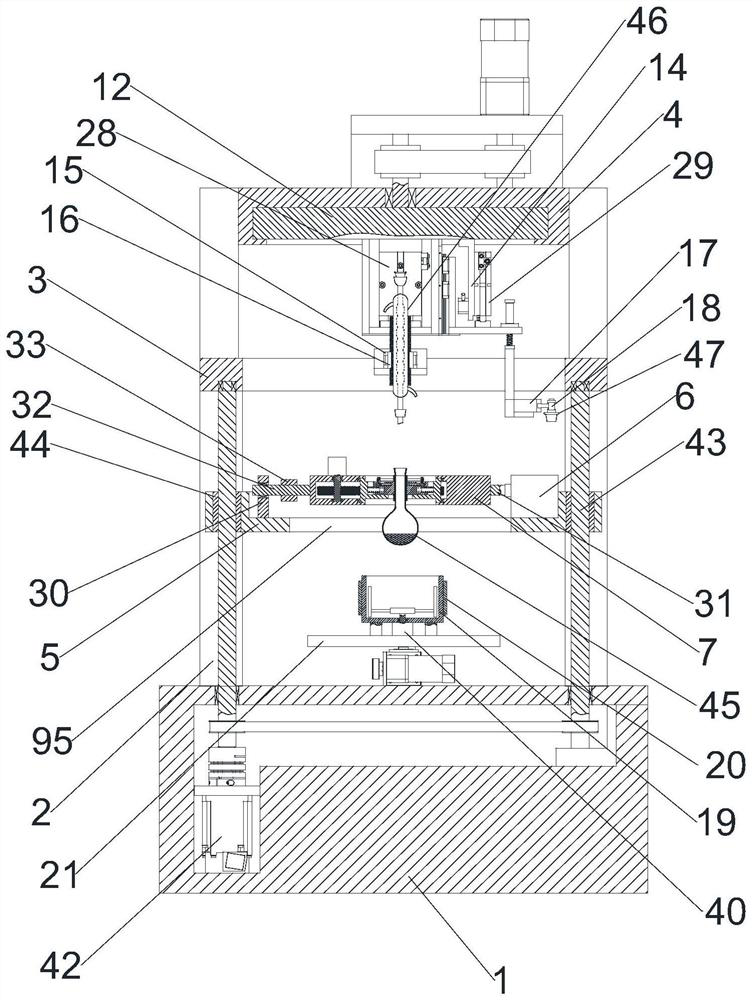

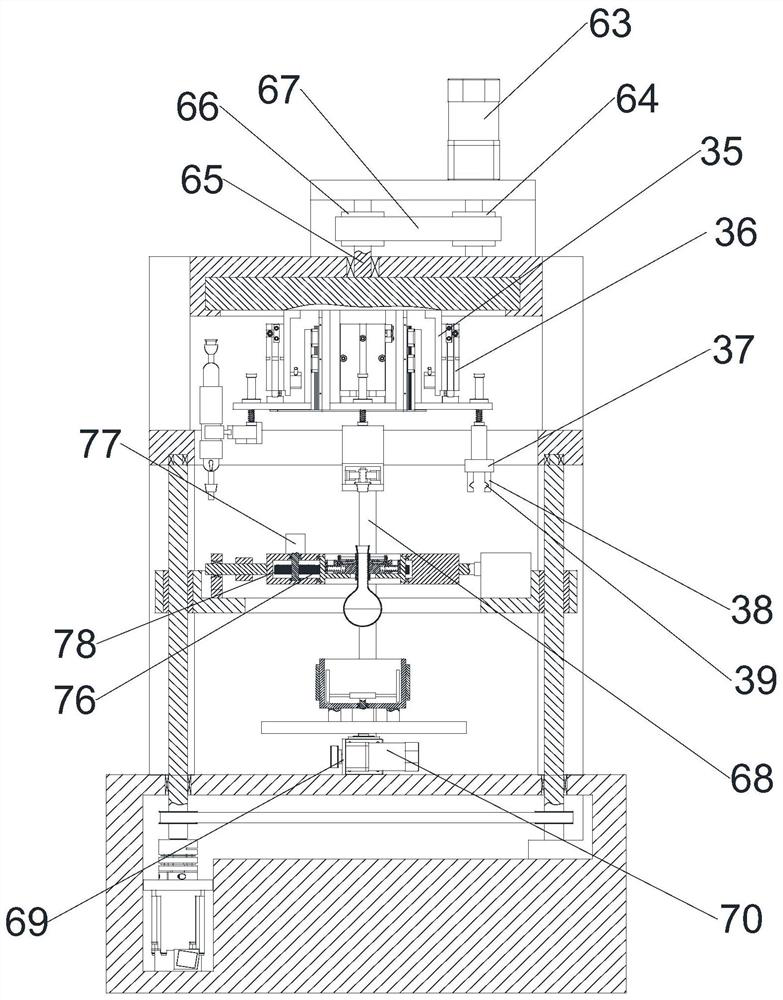

[0054] see Figure 1-16 , a kind of pretreatment device for identifying the quality of chafing dish grease, comprising a support base 1, a support frame 3 is connected to the support base 1 through a base connecting frame 2, and a mounting frame 4 is also connected to the support frame 3;

[0055] The support base 1 or the support frame 3 is also provided with a support plate drive assembly, the output end of the support plate drive assembly is connected with a support plate 5, and the support plate drive assembly acts on the support plate 5, so that: the support plate 5 can be up and down relative to the support base 1 move;

[0056] A rotating drive device 6 is installed on the support plate 5, and the output end of the rotating drive device 6 is connected with a rotating connecting frame 7, and the rotating driving device 6 acts on the rotating connecting frame 7, so that: the rotating connecting frame 7 can rotate relative to the supporting plate 5;

[0057] The rotating ...

Embodiment 2

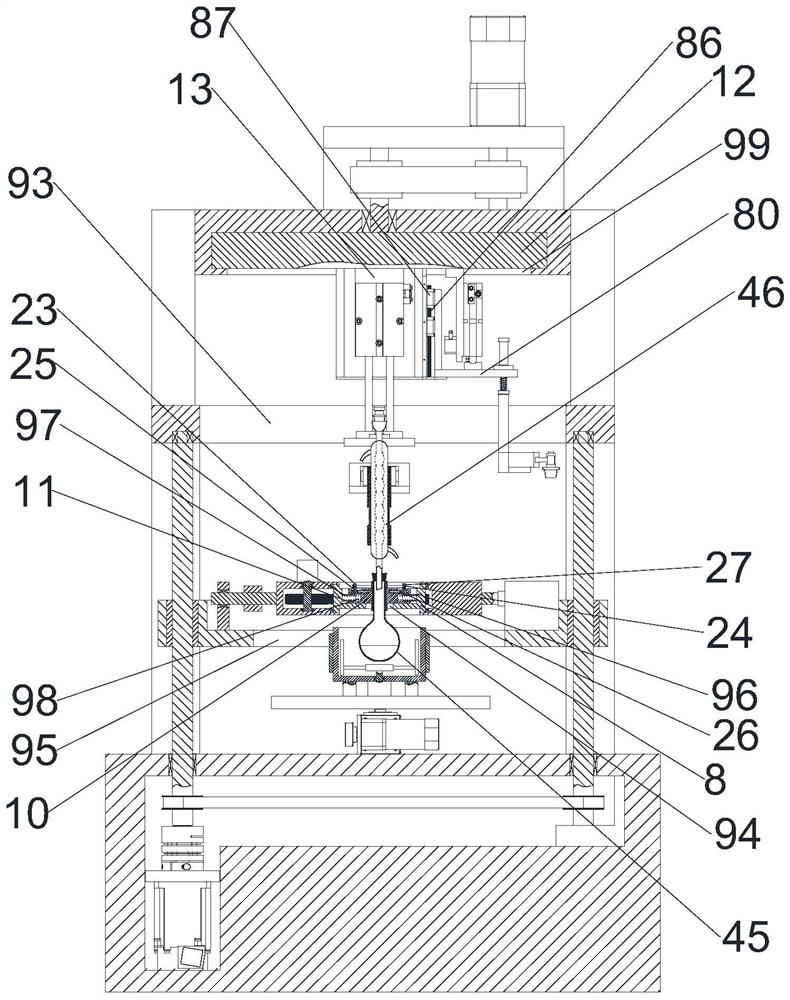

[0070] This embodiment makes the following further limitations on the basis of Embodiment 1: the lower rotating disk drive assembly is installed on the support base 1, the output end of the lower rotating disk assembly is connected to the lower rotating disk 21, and the lower rotating disk 21 is set There are the water bath assembly and the cooling assembly arranged in dislocation with the water bath assembly, and the lower rotating disk drive assembly acts on the lower rotating disk 21, so that: the water bath assembly or the cooling assembly can be located directly below the flask clamping assembly;

[0071] The cooling assembly includes a cooling box 22 .

[0072] In this embodiment, the arrangement of the cooling box 22 allows the flask 45 to be cooled to room temperature rapidly after reflux. During application, first start the lower rotating disk drive assembly to drive the lower rotating disk 21 to rotate, so that the water bath assembly is located directly below the fl...

Embodiment 3

[0076] This embodiment makes the following further limitations on the basis of Embodiment 1: the clamping connection base 8 is rotatably connected to the rotating connection frame 7;

[0077] A clamping connection seat driving assembly for driving the clamping connection seat 8 to rotate is arranged on the rotating connection frame 7 .

[0078] In this embodiment, the clamping connection seat 8 can be rotatably connected to the rotating connection frame 7 through a bearing, and the driving assembly of the clamping connection seat can be started to drive the clamping connection seat 8 to rotate, so that the flask 45 can be driven to rotate. It can evenly receive the heating from the water bath, and it can also facilitate efficient shaking work.

[0079] In order to realize the rotation drive of the clamping connection seat drive assembly to the clamping connection seat 8, the clamping connection seat driving assembly may include a clamping connection seat driven gear 76 sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com