Chip bonding pad structure, chip, wafer and chip bonding pad structure manufacturing method

A chip pad and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as chip function failure, avoid virtual soldering, ensure effective contact, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

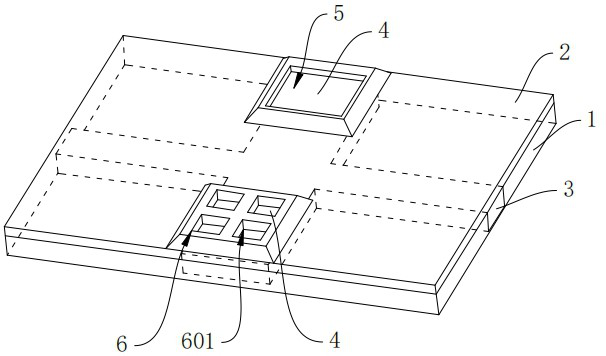

[0062] figure 1 It is a schematic diagram of the chip pad structure provided by an embodiment of the present invention, such as figure 1 As shown, the chip pad structure includes:

[0063] The first insulating layer 1 has grooves;

[0064] The first metal layer 3 is filled in the groove of the first insulating layer 1, and the first metal layer 3 is connected with the internal circuit of the chip to form a conductive channel;

[0065] The second metal layer 4 is formed on the first metal layer 3, and the second metal layer 4 has a pad area for connecting the chip to an external device;

[0066] The second insulating layer 2 covers at least the part of the second metal layer 4 outside the pad area and the first metal layer 3;

[0067] The pad area includes a test pad area 5 and a gold bump pad area 6; the gold bump pad area 6 includes a plurality of sub-pad areas. Among them, the test pad area 5 is used for connecting pads for CP testing after the chip is manufactured, and ...

Embodiment 2

[0101] image 3 It is a schematic diagram of the chip pad structure provided by another embodiment of the present invention, such as image 3 As shown, the chip pad structure includes:

[0102] The first insulating layer 1 has grooves;

[0103] The first metal layer 3 is filled in the groove of the first insulating layer 1, and the first metal layer 3 is connected with the internal circuit of the chip to form a conductive channel;

[0104] The second metal layer 4 is formed on the first metal layer 3, and the second metal layer 4 has a pad area for connecting the chip to an external device;

[0105] The second insulating layer 2 covers at least the part of the second metal layer 4 outside the pad area and the first metal layer 3;

[0106] The pad area includes a test pad area 5 and a gold bump pad area 6; the gold bump pad area 6 includes a plurality of sub-pad areas. Among them, the test pad area 5 is used for connecting pads for CP testing after the chip is manufactured,...

Embodiment 3

[0140] Figure 5 It is a schematic diagram of the chip pad structure provided by another embodiment of the present invention, such as image 3 As shown, the chip pad structure includes:

[0141] The first insulating layer 1 has grooves;

[0142] The first metal layer 3 is filled in the groove of the first insulating layer 1, and the first metal layer 3 is connected with the internal circuit of the chip to form a conductive channel;

[0143] The second metal layer 4 is formed on the first metal layer 3, and the second metal layer 4 has a pad area for connecting the chip to an external device;

[0144] The second insulating layer 2 covers at least the part of the second metal layer 4 outside the pad area and the first metal layer 3;

[0145] The pad area includes a test pad area 5 and a gold bump pad area 6; the gold bump pad area 6 includes a plurality of sub-pad areas. Among them, the test pad area 5 is used for connecting pads for CP testing after the chip is manufactured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com