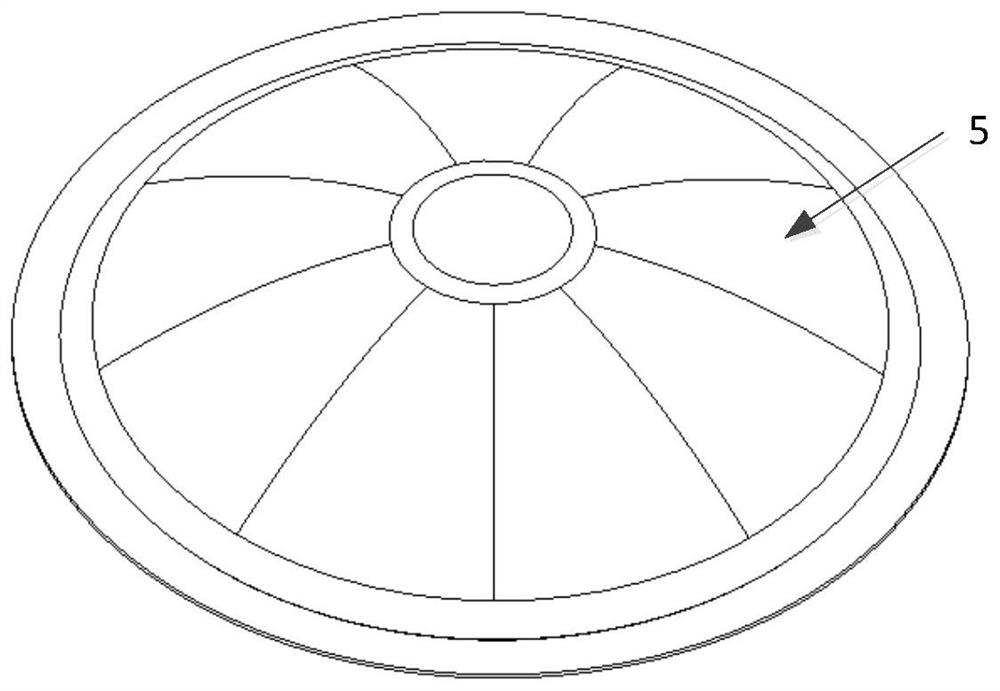

Integrated forming method of carbon fiber three-way fabric composite material reflecting surface for umbrella antenna

A three-way fabric and composite material technology, applied in antennas, folded antennas, antennas suitable for movable objects, etc., can solve problems such as the influence of profile accuracy, and achieve the effect of reducing weight, good appearance quality and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] (1) Preparation of raw materials: Coat ZS-NJ-D955-6 organic silica gel on the surface of all carbon fiber tows, vulcanize at room temperature, and use them as raw materials for three-way fabric weaving. The carbon fiber tow is polypropylene-based carbon fiber, the tow size is 1K, the longitudinal elastic modulus of the tow is 96.6GPa, the transverse elastic modulus is 3.8MPa, and the shear elastic modulus is G 12 =G 13 =0.98MPa and G 23 = 1.36 MPa.

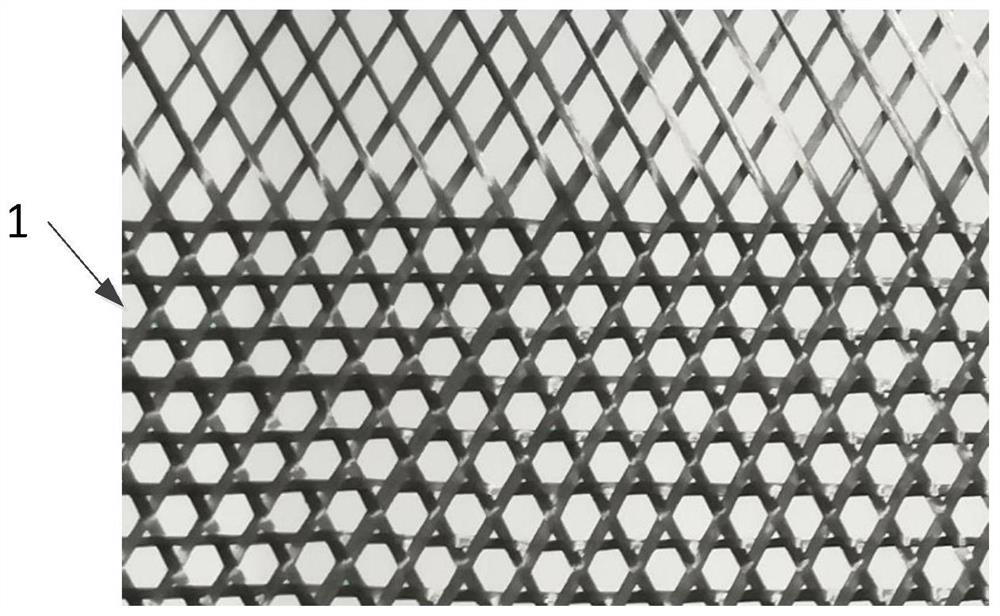

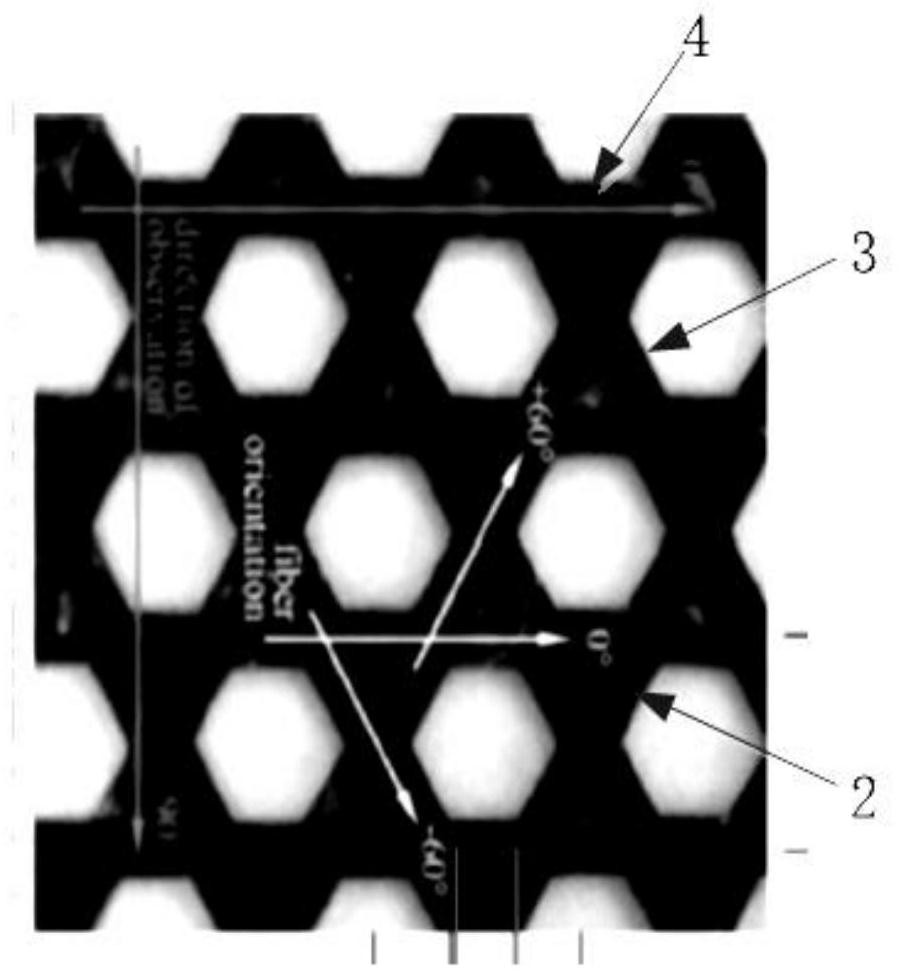

[0064] (2) Carbon fiber three-way fabric weaving: fix the carbon fiber tow in the direction of 60°, after the tow is fixed in the direction of 60°, take the carbon fiber tow and fix it in the direction of -60°, and finally use the needle to guide the carbon fiber according to the figure 1 and figure 2 Weave carbon fiber tows in the 0° direction according to the interweaving law to form a carbon fiber three-way fabric with a regular hexagonal pore network structure, weaving a total of 30 square meters. The diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Shear modulus of elasticity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com