Low-temperature coating equipment and production process

A kind of equipment and coating technology, applied in the field of low temperature coating equipment and production technology, can solve the problems of inability to guarantee coating consistency, easy to destroy product activity, uneven coating effect, etc., to ensure coating effect and large production capacity , the effect of improving the function effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] After the product is coated at low temperature by the present invention, it can be transported by refrigeration or cold chain:

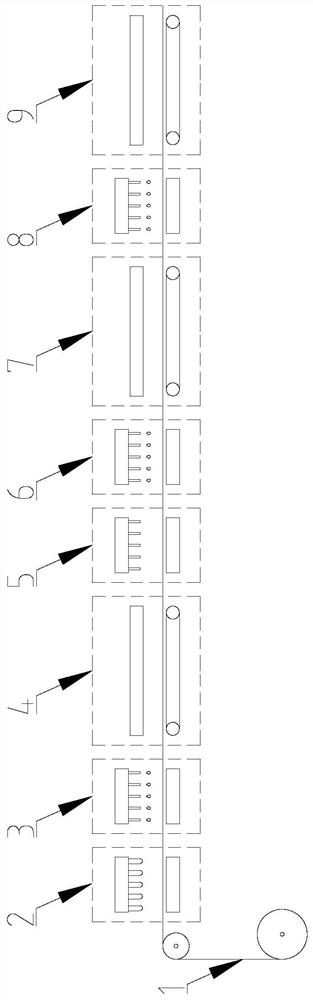

[0044] Such as figure 1 As shown, it is a kind of low-temperature coating equipment provided by the present invention, which consists of a packaging material placement station, a packaging material transmission mechanism 1, a molding equipment 2, a filling equipment 3, a quick freezing equipment 4, a molding equipment 2 5, a filling equipment It consists of filling equipment 26, quick-freezing equipment 27, filling equipment 38 and quick-freezing equipment 39, control system, material-liquid circulation pipeline and power equipment and other auxiliary parts.

[0045] The workflow of the above equipment is as follows:

[0046] 1. After the packaging material is fixed at the packaging material placement station, it is gradually unfolded under the action of the control system and power equipment and moves from the front end to the rear end throu...

Embodiment 2

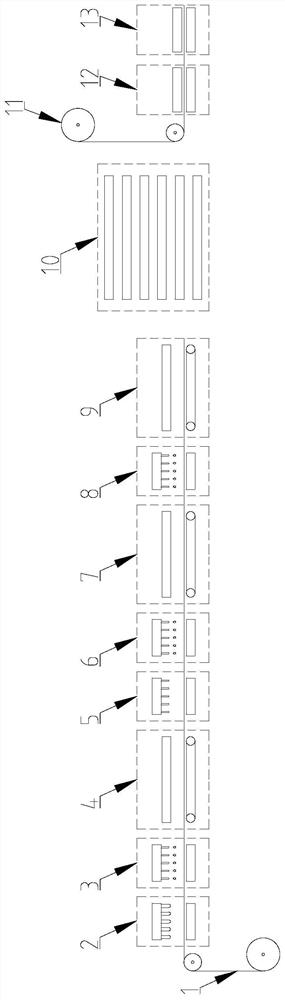

[0056] Through the present invention, the product can be coated at low temperature, and then freeze-dried and sealed:

[0057] Such as figure 2 As shown, it is a kind of low-temperature coating equipment provided by the present invention plus freeze-drying and film-coated sealing treatment equipment. The packaging material is placed at the station, and the packaging material transmission mechanism 1, molding equipment-2, filling equipment-3, quick-freezing Equipment 1 4, forming equipment 2 5, filling equipment 2 6, quick-freezing equipment 2 7, filling equipment 3 8, quick-freezing equipment 3 9, freeze-drying equipment 10 (vacuum freeze-drying, hereinafter referred to as "freeze-drying"), top film It is composed of packaging material placement equipment 11, film sealing equipment 12, punching equipment 13, control system, material-liquid circulation pipeline, power equipment and other auxiliary parts.

[0058] The workflow of the above equipment is as follows:

[0059] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com