Two-pass deep drawing forming method for long annular lip with deep U-shaped section and beak-shaped middle

A secondary deep-drawing, beak-like technology, used in forming tools, aircraft parts, metal processing equipment, etc., can solve the problems of deep U-shaped narrow and long annular closed aluminum alloy lips with great disparity in length and width ratio, and reduce drawing. The effect of deep forming times, easy promotion and realization, and reduction of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

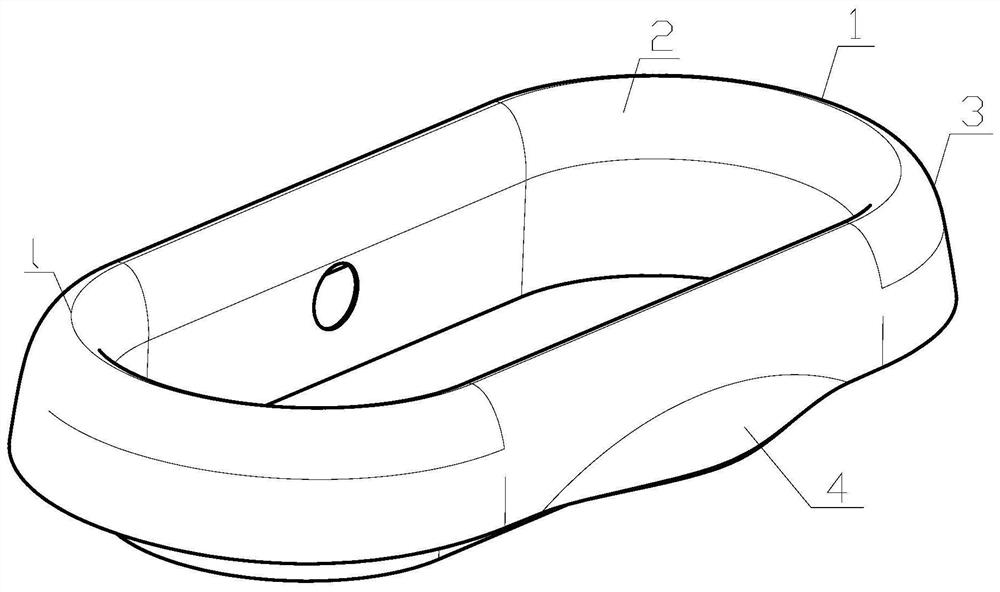

[0052] Referring to the accompanying drawings, the aircraft sheet metal parts provided by the embodiment are as figure 1 As shown, the air inlet lip 1 is in the shape of an oblong ring as a whole, with a U-shaped cross-section, a wide ratio of length to width, a relatively narrow width direction, and a deep U-shaped cavity. The aluminum alloy lip 1 is composed of the lip inner wall 2 and the lip outer wall 3. The lip inner wall 2 and the lip outer wall 3 intersect at the boundary line 1 of the inner and outer walls of the lip. The assembly relationship of the lip 1 is complicated, and the precision of the inner and outer surfaces is high. The traditional two-pass deep drawing cannot form a deep U-shaped narrow and long ring-shaped closed aluminum alloy lip with a large length-to-width ratio.

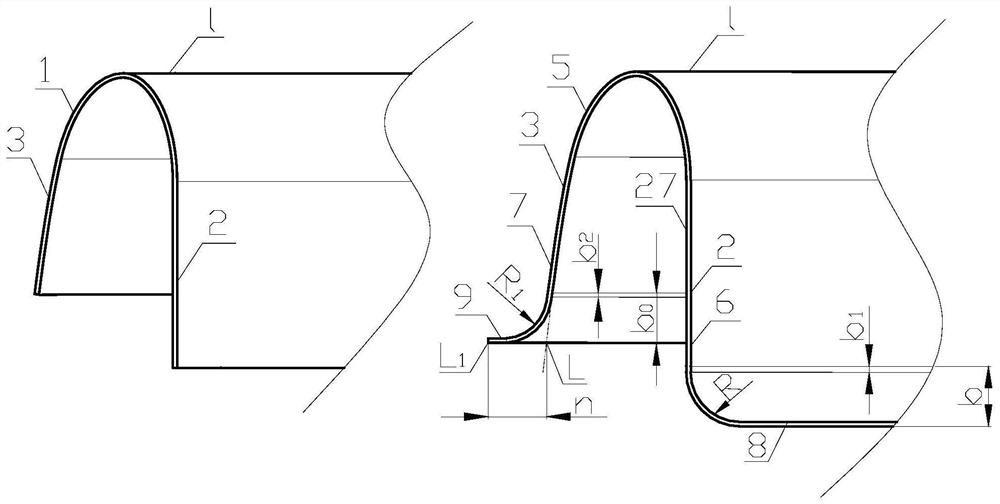

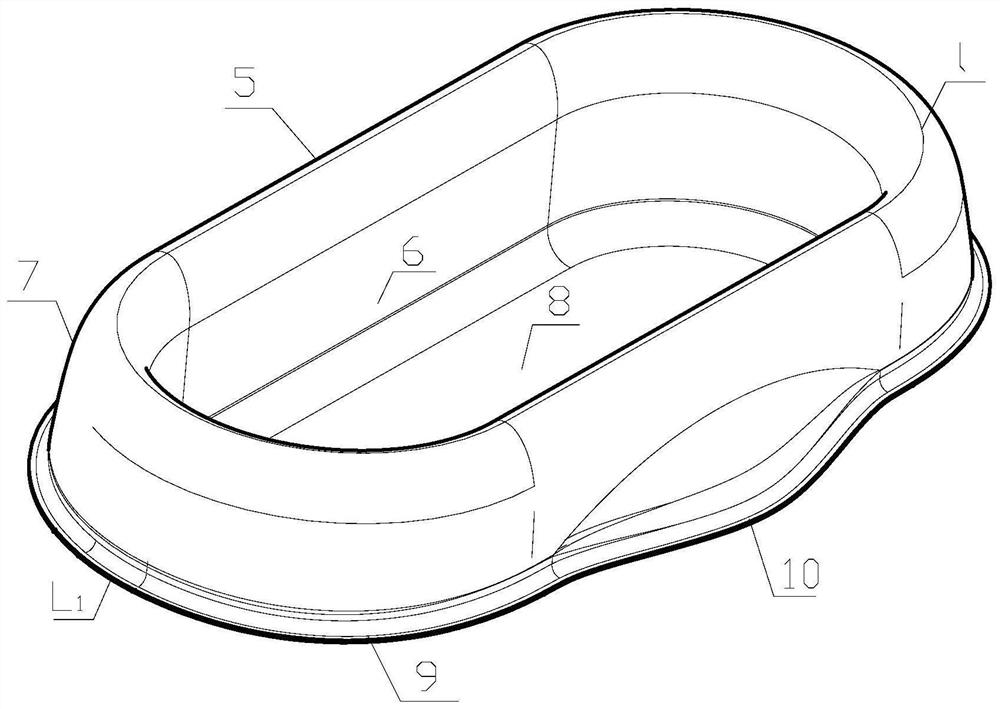

[0053] Such as Figure 2 to Figure 12 As shown, a two-pass deep-drawing forming method for a beak-shaped long annular lip in the middle of a deep U section includes the following steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com