Accurate forming method and accurate forming system in TIG electric arc additive manufacturing process

An additive manufacturing and precise technology, applied in the field of precise forming systems, can solve problems such as low stability and difficult precise control of forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

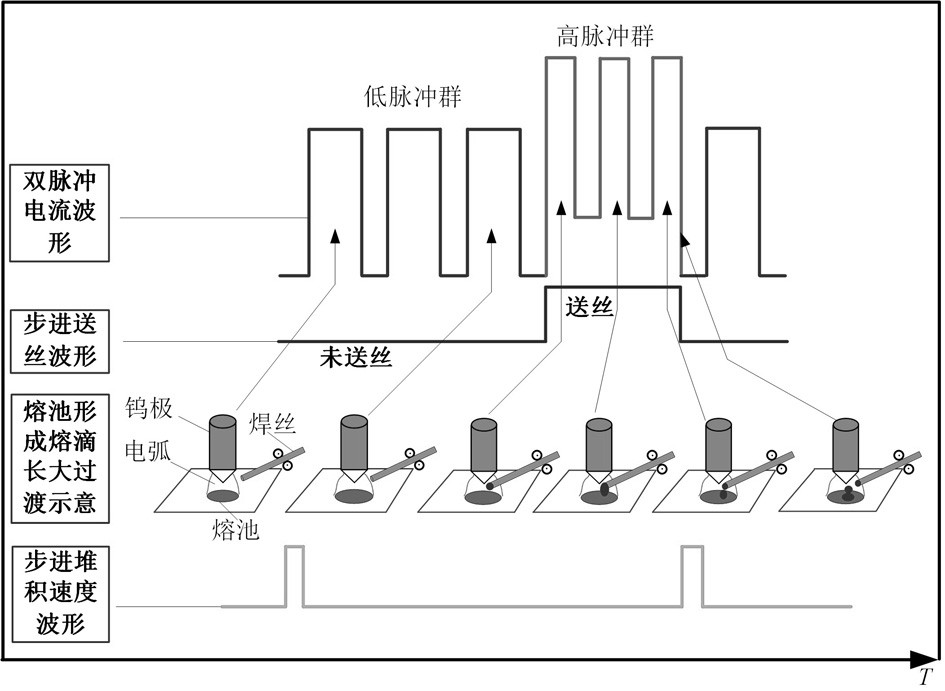

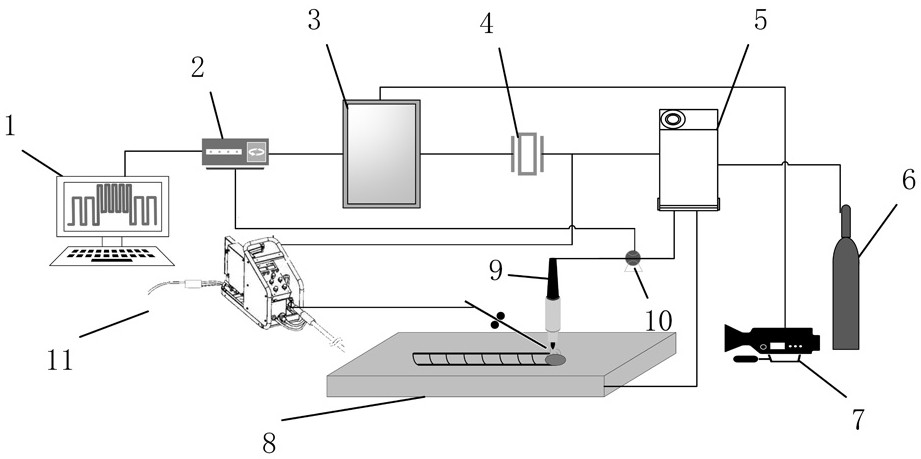

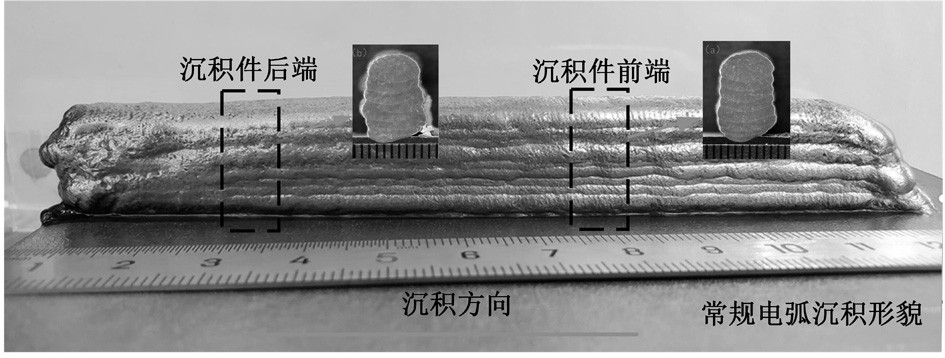

[0025] An embodiment of the precise forming method of a TIG arc additive manufacturing process of the present invention, specifically, the high-low pulse current group waveform is used as the output mode of the arc current, and the high-low pulse current group waveform includes continuous interval output. High pulse current group band and low pulse current group band, at the same time use the matching current wire feeding waveform to control the wire feeding timing of the welding wire, control the welding wire to feed in the high pulse current group band, and control the wire feeding stop in the low pulse current group band . The low pulse current group-band arc is used to melt the base metal and maintain the stable combustion of the arc, and the high-pulse current group-band arc is used to melt the welding wire to form a droplet and transition into the molten pool and stir the molten pool. The whole process of arc material addition is carried out under the protective gas. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com