Laser welding method for high-grade silicon steel plate

A technology of laser welding and silicon steel plate, which is applied in laser welding equipment, welding equipment, furnaces, etc., can solve the problems of high weld seam breakage rate and high energy consumption, so as to improve weld seam quality, reduce energy consumption, and reduce welding The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

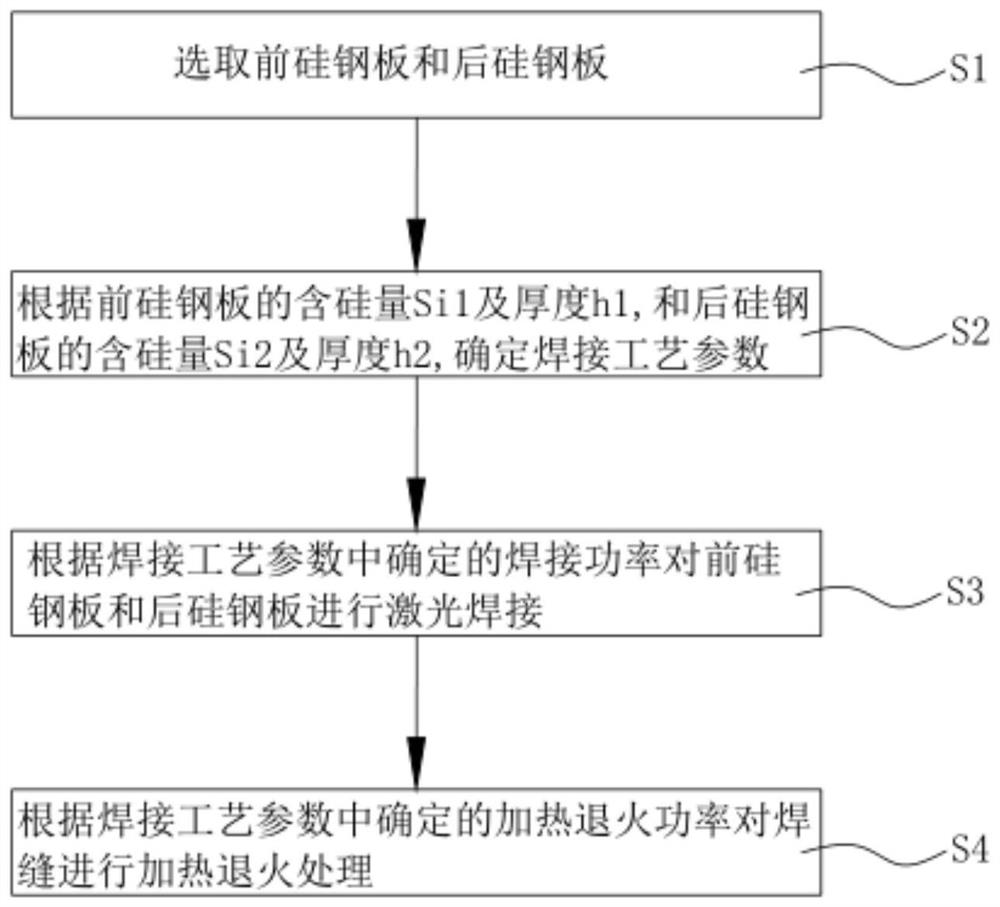

[0044] A laser welding method for high-grade silicon steel plates, comprising the following steps:

[0045] Step S1: Obtain the silicon content Si1 and thickness h1 of the front silicon steel plate, and the silicon content Si2 and thickness h2 of the rear silicon steel plate; wherein, the silicon content and thickness of the front silicon steel plate and the rear silicon steel plate must meet the following preset conditions at the same time : 4.0mm≤h1+h2≤5.5mm, 4.0%≤Si1+Si2≤6.4%, and │h1-h2│≤0.30mm, │Si1-Si2│≤0.5%.

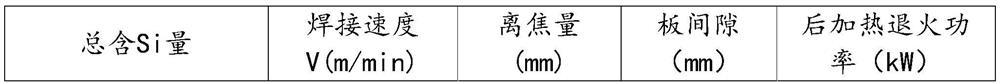

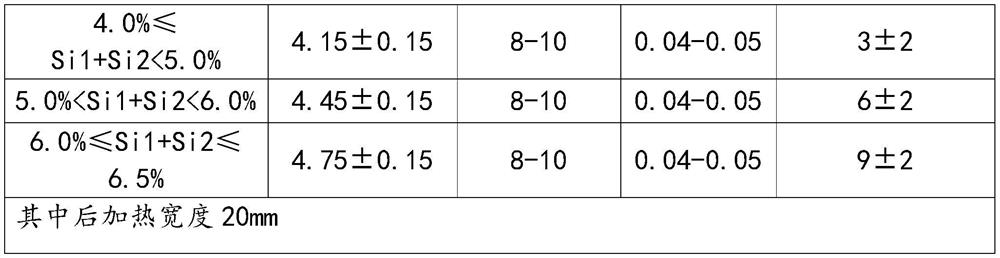

[0046] Step S2: According to the range interval of the total silicon content (Si1+Si2) of the two silicon steel plates before and after, obtain the total silicon content (Si1+Si2) in the database corresponding to the total silicon content, welding speed and heating annealing power. The welding speed V and heating annealing power corresponding to the range interval of +Si2), the welding power P is calculated according to the welding speed V and the total thickness ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap