High-elastic jacquard vamp fabric and production process thereof

A fabric and shoe upper technology, applied in the field of high elastic jacquard jacquard upper fabric and its production process, can solve the problems of lack of elasticity and anti-pull function, poor comfort, breakage, etc., and achieve high elasticity and anti-pull function. , High comfort and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Such as figure 1 As shown, a high-elastic jacquard jacquard shoe upper fabric is made of high-elastic fabric. The high-elastic fabric is composed of 5% spandex, 50-65% polyester, and 35-50% nylon or Cationic fibers.

[0043] A kind of production method of high-elastic jacquard jacquard upper fabric, the production method steps are as follows:

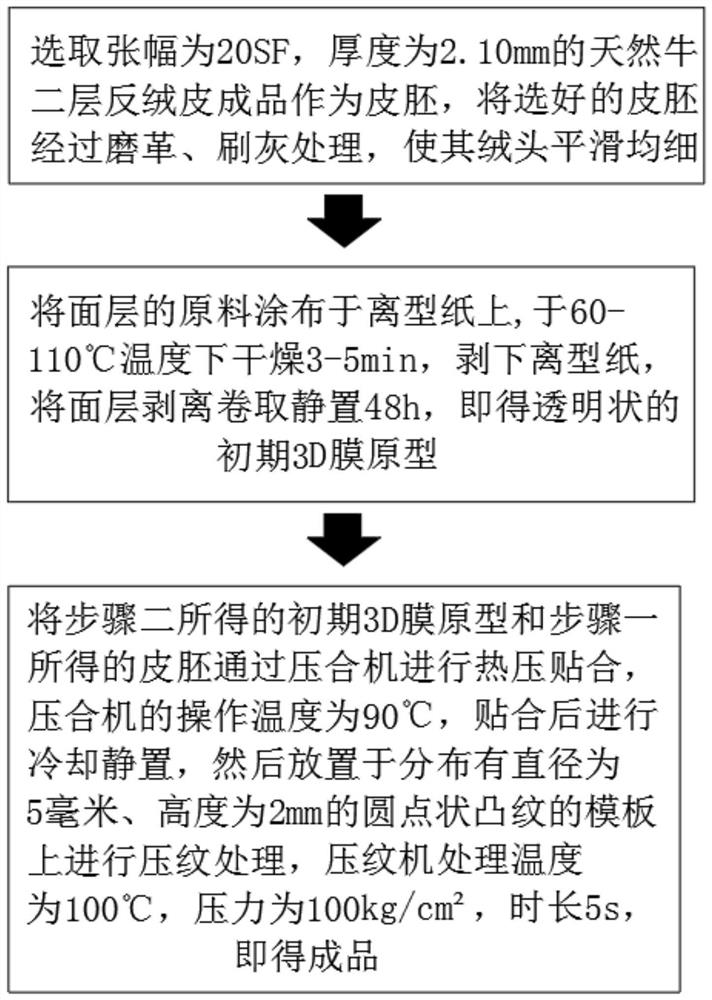

[0044] Step 1. Select a finished natural bovine two-layer suede leather product with a width of 20 SF and a thickness of 2.10 mm as the skin embryo, and process the selected skin embryo through grinding and brushing to make the pile smooth and fine;

[0045] Step 2. Coat the raw materials of the surface layer on the release paper, dry at 60-110°C for 3-5 minutes, peel off the release paper, peel off the surface layer, take it up and let it stand for 48 hours to obtain a transparent initial stage. 3D film prototype;

[0046] Step 3. The initial 3D film prototype obtained in step 2 and the skin embryo obtained in step 1 are hot-...

Embodiment 2

[0048] Embodiment 2 is a further improvement to Embodiment 1.

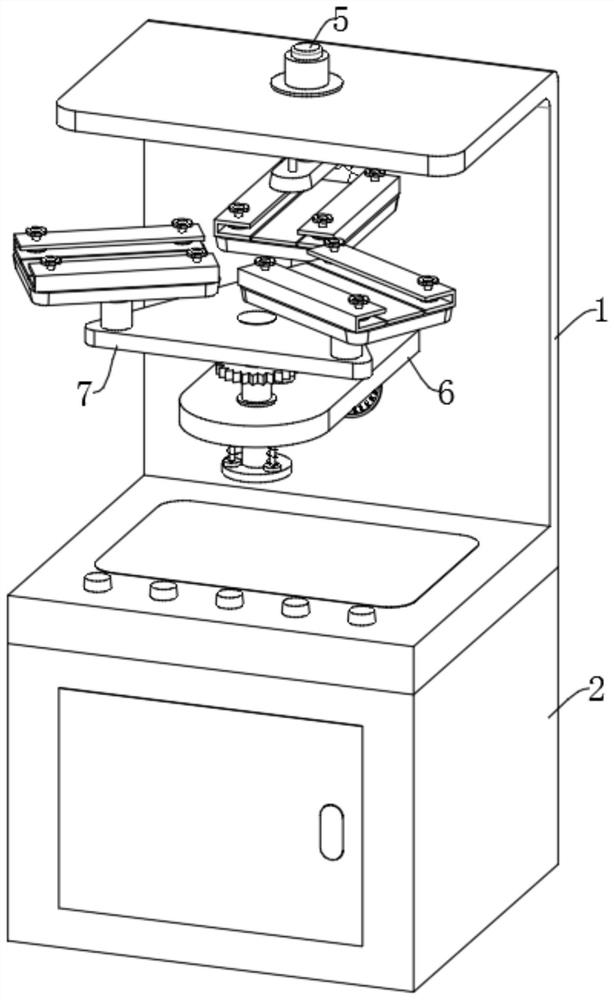

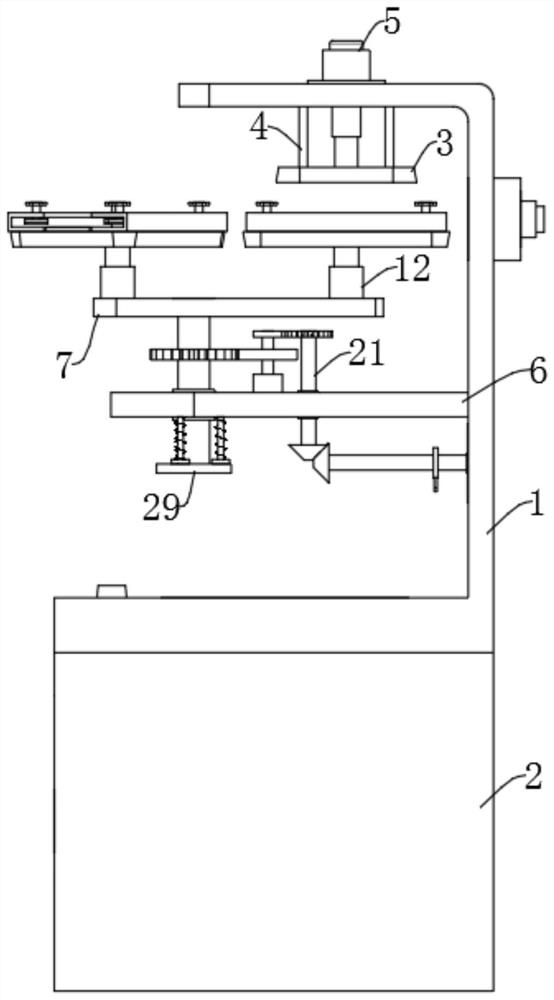

[0049] Such as figure 2 , 3 , 8, 9, 10, and 11 show a kind of high-elastic jacquard jacquard upper fabric production device, the production device is the pressing machine in step 3, including frame 1, control mechanism, pressing mechanism, switching mechanism, The carrying mechanism and the counting mechanism, the control mechanism is installed on the frame 1, the pressing mechanism is arranged in the frame 1, the control mechanism can control the pressing mechanism to work, the carrying mechanism is arranged on the switching mechanism, and the switching mechanism and the counting mechanism are both arranged on the the inner side of rack 1;

[0050] The control mechanism includes a chassis 2, which is located at the bottom of the frame 1, and is fixedly connected between the chassis 2 and the frame 1. The pressing mechanism includes a pressing plate 3, two guide rods 4 and a hydraulic cylinder 5, and the pressi...

Embodiment 3

[0053] Embodiment 3 is a further improvement to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com