Downhole pipe column cutting tool

A technology for cutting tools and downhole pipe strings is applied in the field of tools for cutting downhole pipes, and can solve the problems of pollution, uneven cutting of pipe strings, uneven cutting of homogenous energy and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

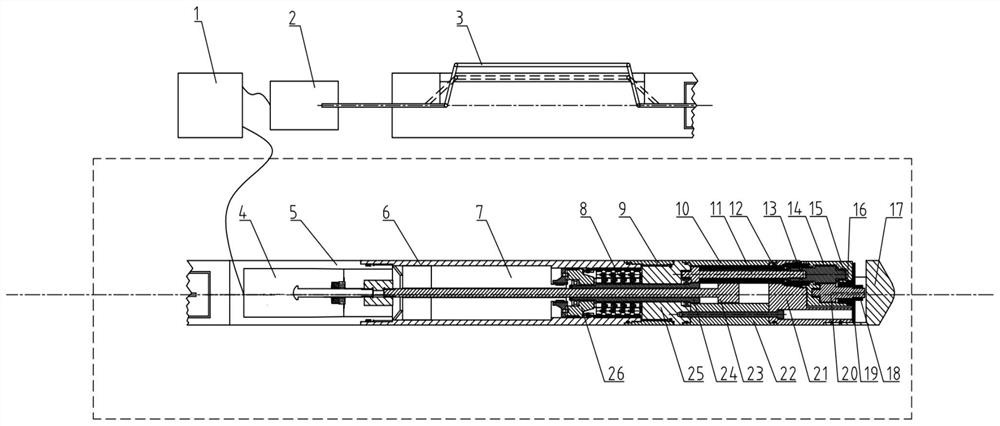

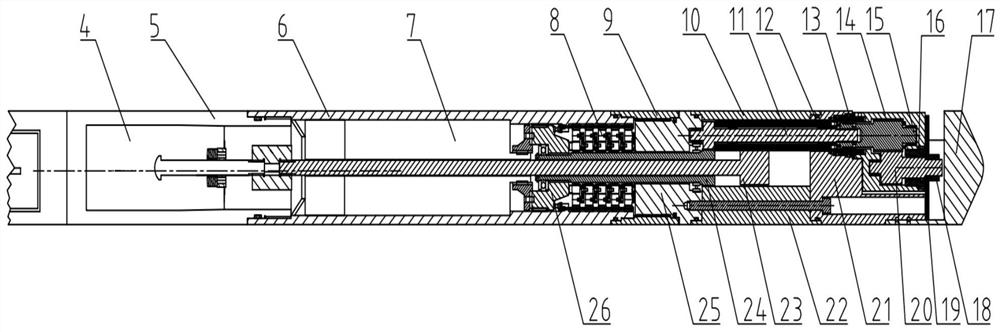

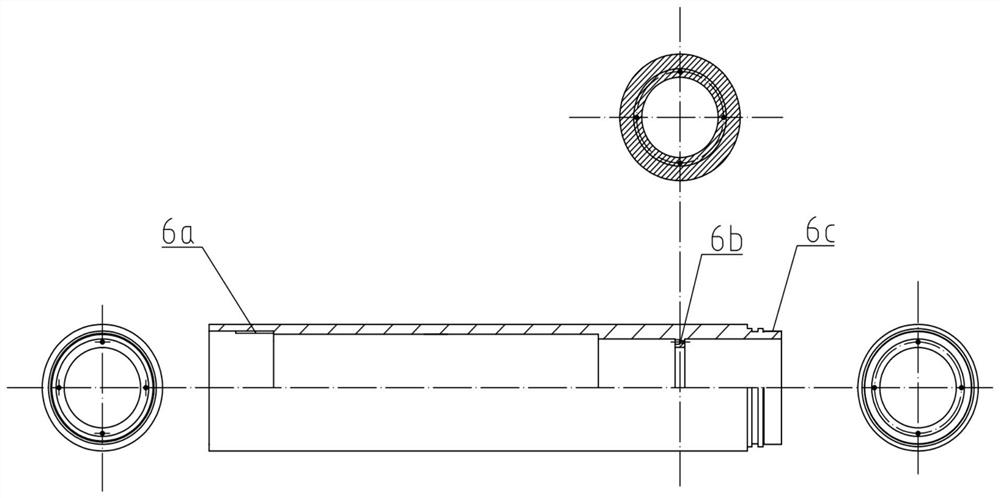

[0015] 1. If Figure 1-Figure 4 As shown, a downhole pipe string mechanical cutting tool is composed of a power supply 1, an anchor electric cylinder 2, an anchor mechanism 3, a push knife electric cylinder 4, a tool casing 5, a motor casing 6, a hollow shaft downhole motor 7, and a multi-stage Planetary gear reducer 8, cutting head rotating bracket 9, cutting head housing 10, tool rotation transmission gear shaft 11, helical spline shaft 12, transmission gear sleeve 13, tool gear shaft frame 14, transmission gear shaft 15, tool gear shaft Set 16, lead cone 17, end cover 18, milling disc 19, tool gear shaft 20, tool gear shaft suspension 21, cutting head shell 22, zigzag push block 23, tool rotation drive hollow gear shaft 24, tool revolution drive hollow Axle 25, motor drive wheel 26 form. It is characterized in that: the left and right ends of the motor casing 6 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com