Corrosion inhibitor evaluation method for deepwater natural gas pipeline under high gas phase flow rate working condition

A natural gas pipeline and evaluation method technology, applied in the field of deepwater natural gas pipeline transportation, can solve the problems of inaccurate evaluation of corrosion inhibitor anticorrosion effect and inability to form an evaluation method, and achieve the effect of accurate and reasonable evaluation experiment of corrosion inhibitor and scientific and accurate formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

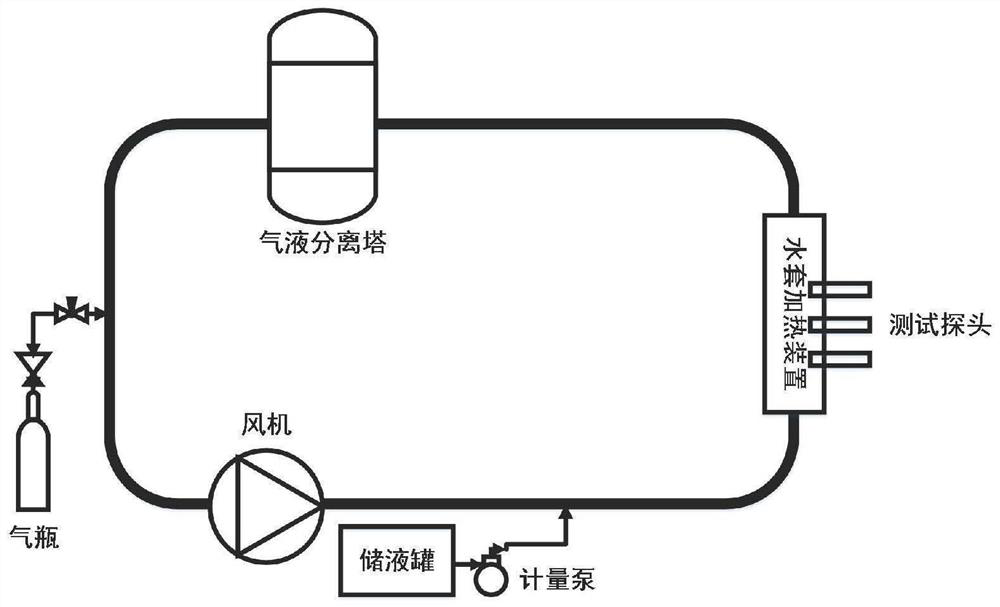

Method used

Image

Examples

Embodiment 1

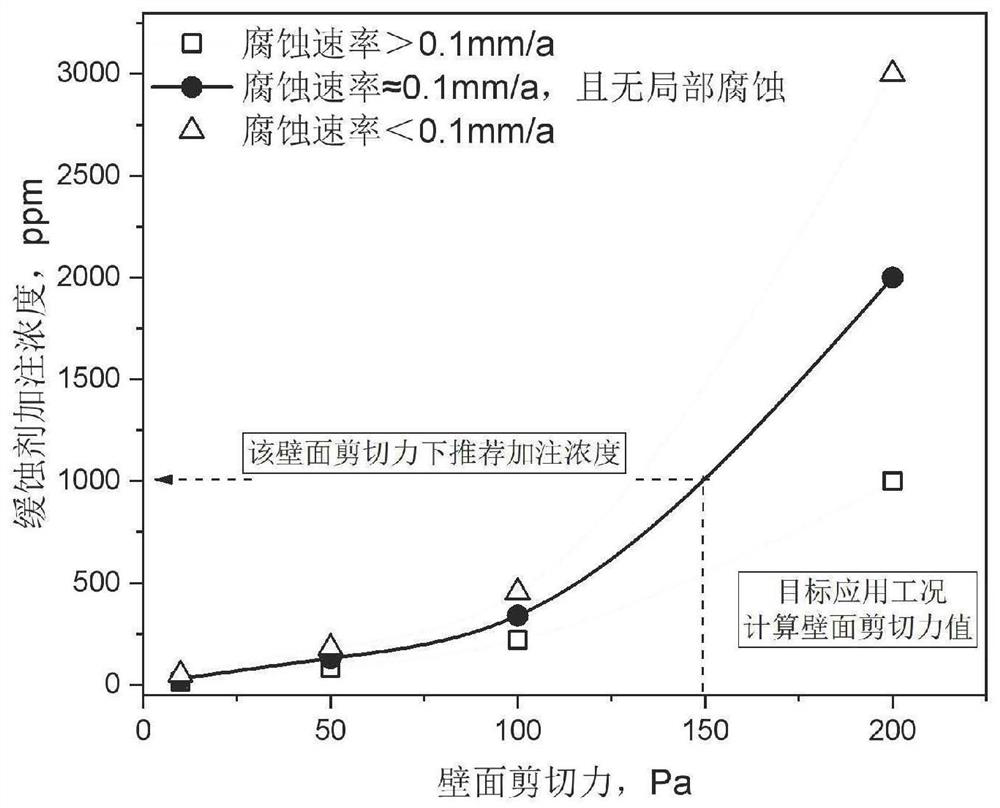

[0050] Embodiment 1 provides a corrosion inhibitor evaluation method for deep-water natural gas pipelines under high gas phase flow rate conditions, comprising the following steps:

[0051] Step A: Carry out the investigation of the service environment of deep-water natural gas pipelines. The investigation objects include the material and diameter of submarine pipelines, the composition of deep-water water quality, the delivery temperature, delivery pressure, gas flow rate, liquid holdup, CO 2 content, H 2 S content, organic acid content, and type of corrosion inhibitor;

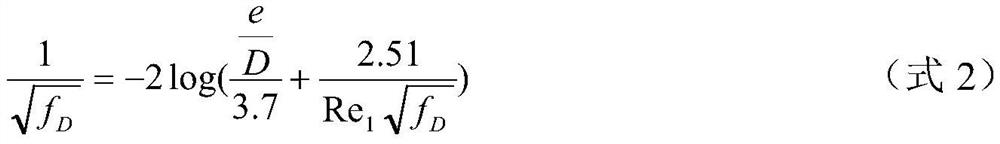

[0052] Taking a natural gas pipeline in a certain place in the South my country Sea as an example, the submarine pipeline uses X65 steel pipes with a diameter of 100mm; the deep water quality composition is: Cl - The content is 1000mg / L, Ca 2+ The content is 300mg / L, HCO 3 - The content is 50mg / L, Na + : 323mg / L; The natural gas transported in the submarine pipeline has a delivery temperature of 60°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com