Wind power generation blade crack detection system and detection method thereof

A technology for detecting wind power blades and cracks, applied in the field of wind farms, can solve problems such as affecting the rotational speed of wind blades, affecting normal operation, uncontrollable wind speed, etc., to achieve the effect of ensuring accuracy and avoiding incomplete acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] There are many devices or systems currently used to monitor power generation blades, but some of them will be affected by the wind and cannot be accurately judged. The other part will be affected by the luminosity and cannot be accurately judged. In some cases, although the position of the crack can be accurately photographed, it is impossible to judge whether the crack meets the maintenance standard, because in many cases, the small crack does not need to be repaired immediately, and can be unified after it expands to a certain extent. repair.

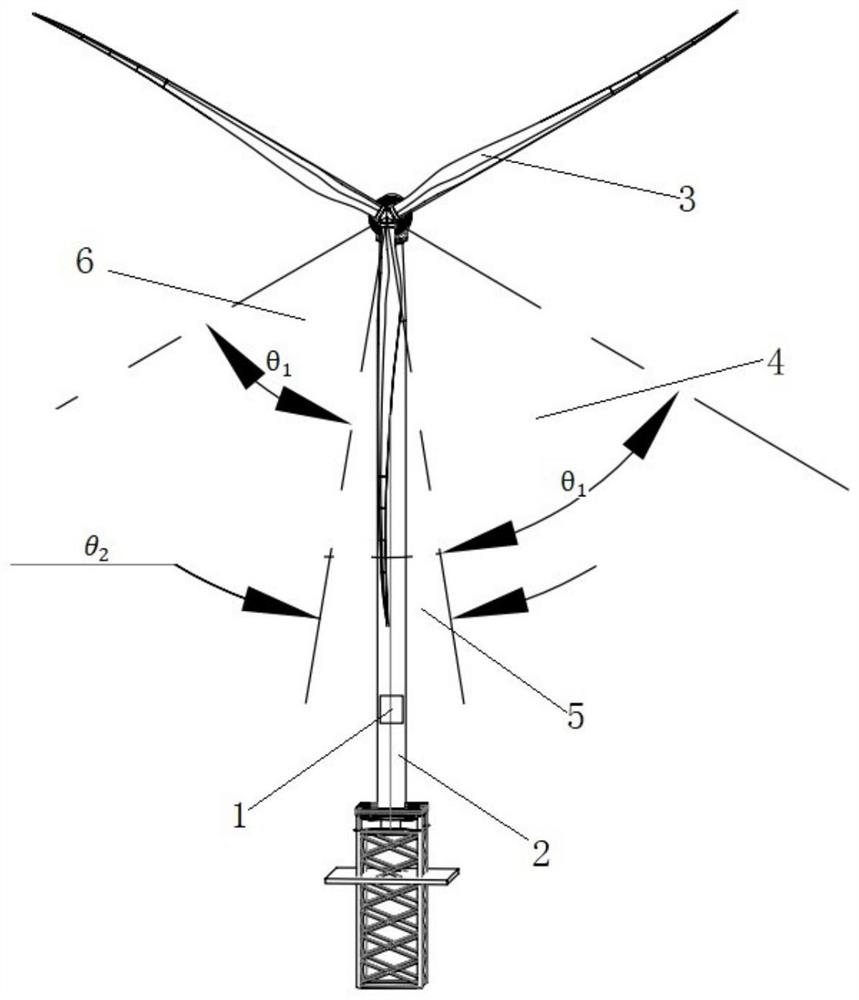

[0057] Therefore, in order to solve the above-mentioned technical problems and technical effects, this embodiment discloses a crack detection system for wind power blades 3, such as figure 1 As shown, the column 2 is included, and the column 2 is erected on the ground. And the top of the column 2 is installed with a fan assembly, and the fan assembly is connected with a fan blade assembly through transmission. Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com