Food turnover box warehouse-in and warehouse-out management and tracing method based on whole circulation path

A turnover box, in-out and out-of-warehouse technology, applied in the direction of logistics, data processing applications, collaborative operation devices, etc., can solve the problems of low management efficiency, time-consuming and labor-intensive, and increased costs, so as to reduce management costs, facilitate material management, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

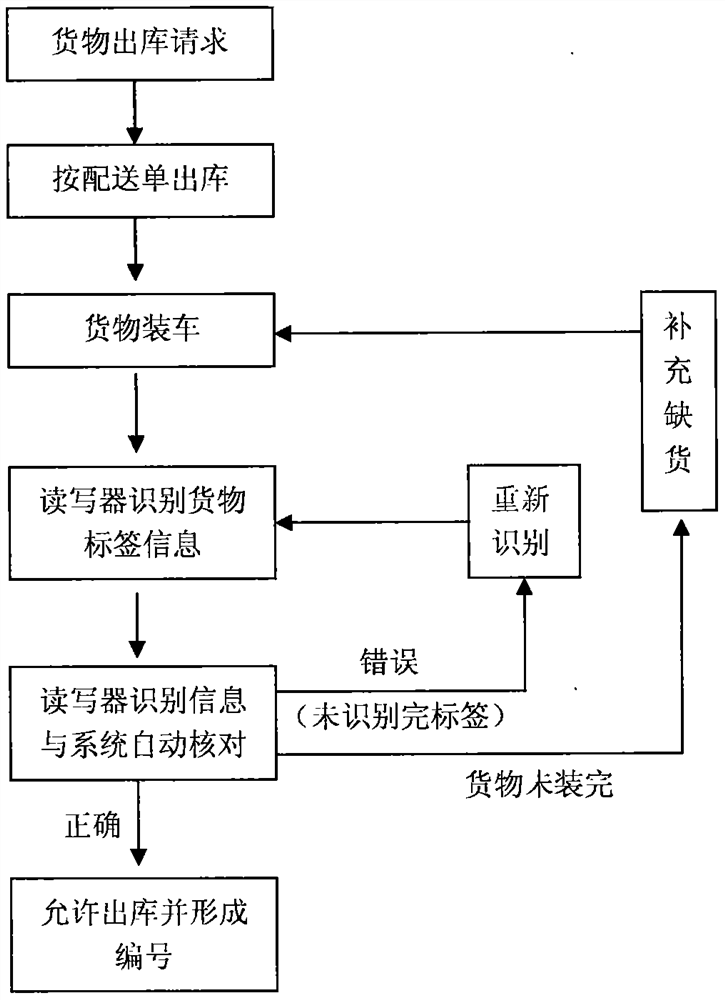

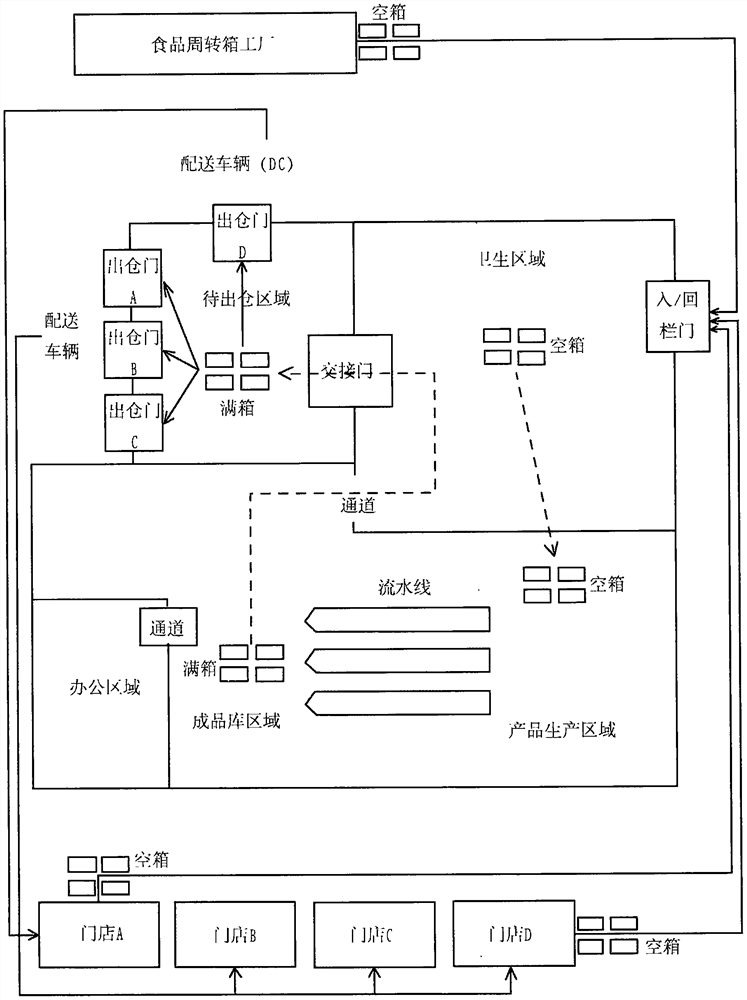

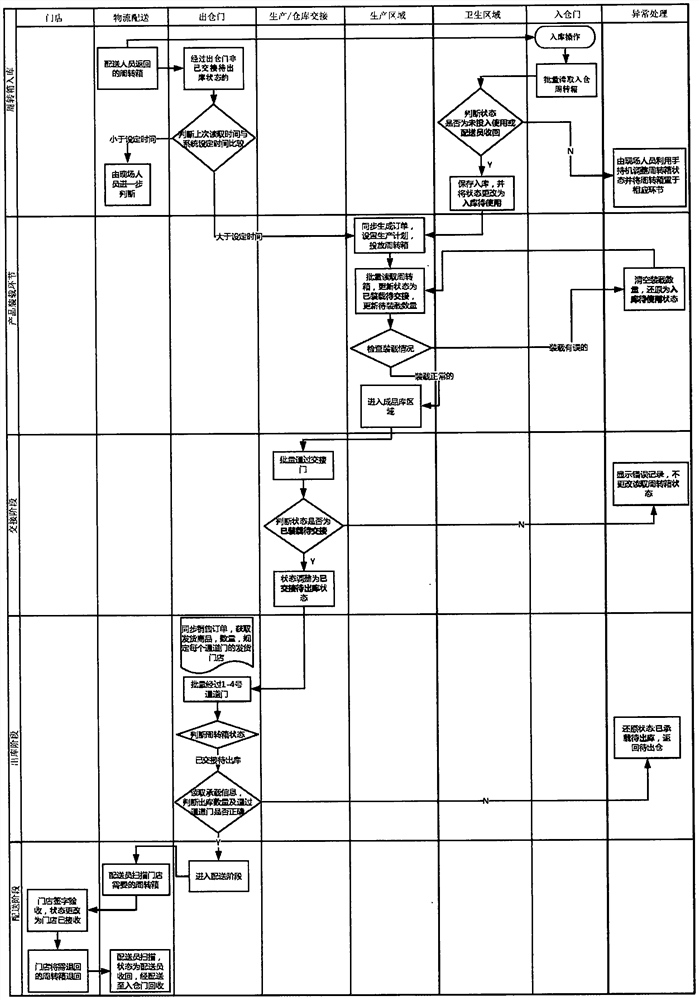

[0084] Such as figure 1 As shown, the entire circulation of food turnover boxes is divided into three parts, namely, food turnover box factory operations, customer factory operations (customers, food factories), and logistics distribution / recycling operations.

[0085] 1. Food turnover box factory link

[0086] The work in this link is divided into: the writing of the basic identity information of the electronic chip, and the production of the food turnover box with the chip attached. Write the basic identity information of the electronic chip, including the underlying basic code of the electronic chip (EPC code) and some naming information required by the customer (material number, name, color, purpose, purchase time, etc., reserve 3-5 pieces of custom information edit column); production of food turnover boxes, including production of turnover boxes and implantation of electronic chips.

[0087] 2. Customer factory link

[0088] The circulation of food turnover boxes in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com