Field planting vegetable harvester

A harvester and vegetable technology, applied in harvesters, pickers, agricultural machinery and implements, etc., can solve the problems of high cost, low efficiency, inability to meet mass production, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

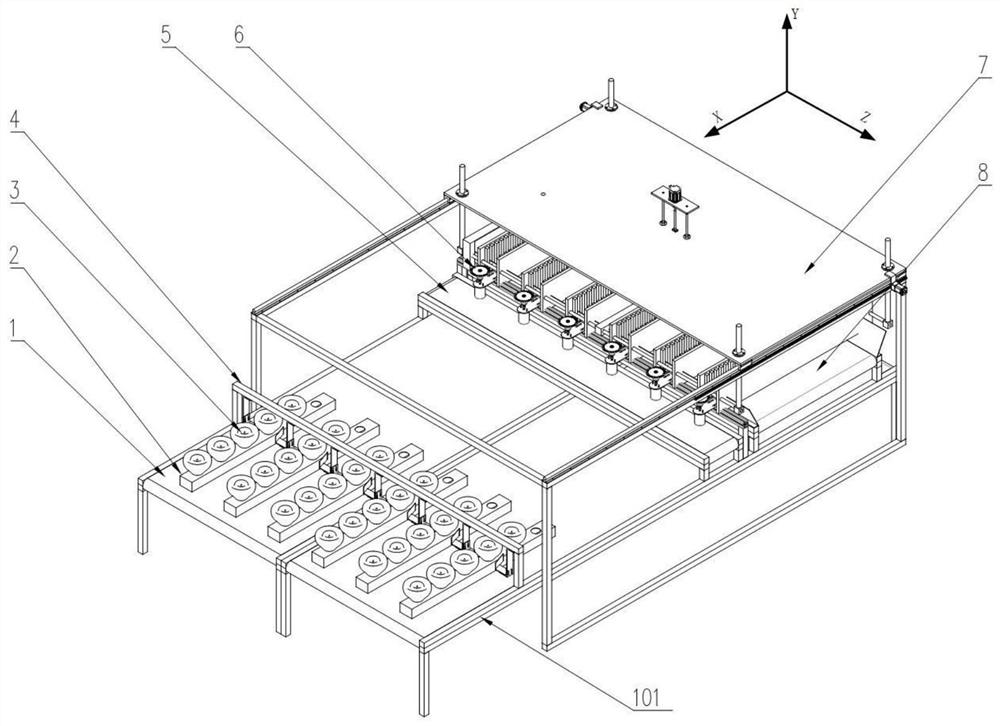

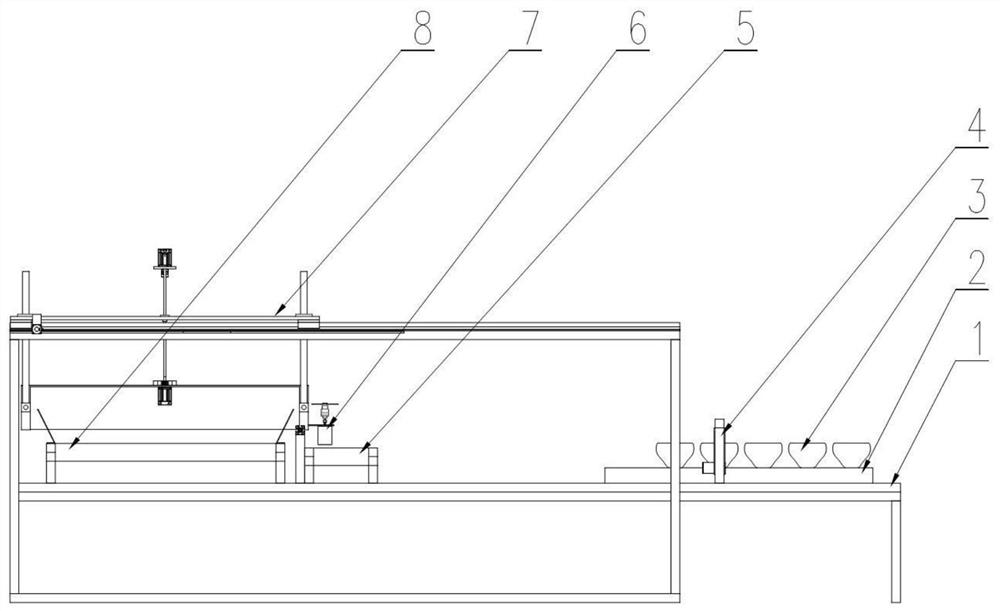

[0064] like Figure 1 to Figure 7 As shown, a planting vegetable harvester provided by the embodiment of the present invention includes, according to the conveying direction of vegetables: a planting tank 2 with vegetables planted there, a vegetable root conveying mechanism 5, a root cutting mechanism 6, and a vegetable conveying mechanism 8;

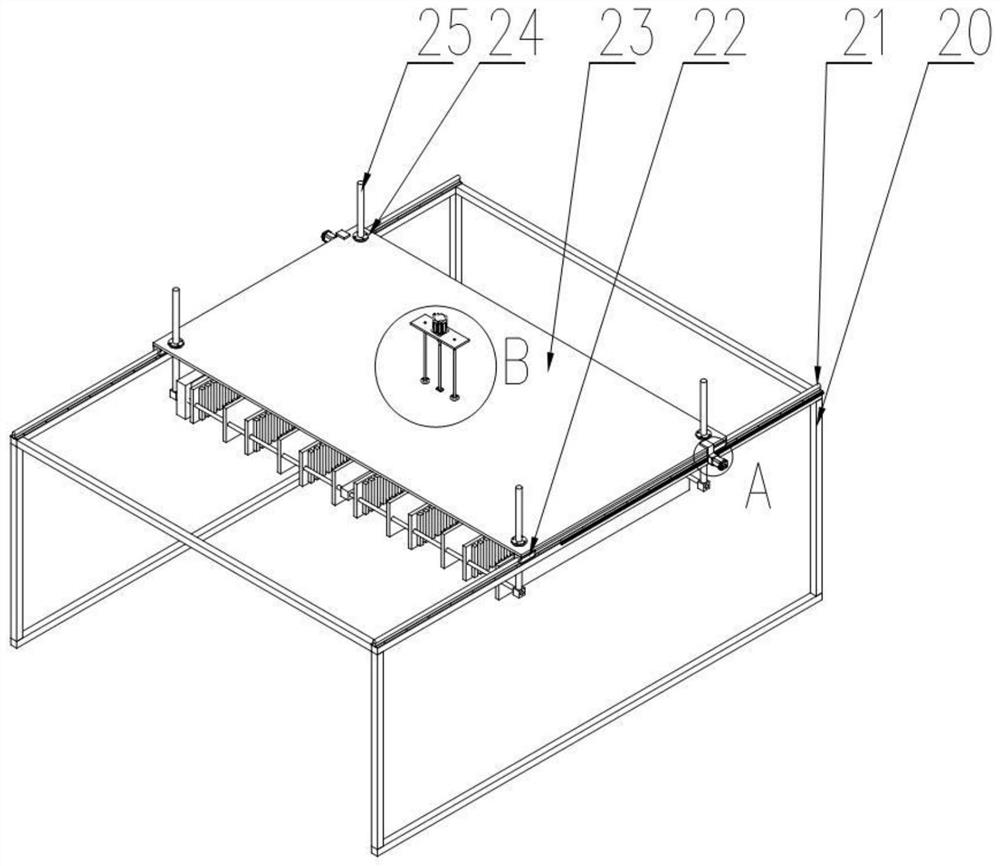

[0065] The planting vegetable harvester also includes a planting trough conveyor belt 1 and a frame 20;

[0066] An X-direction mobile component integrated on the frame 20;

[0067] A Y-direction movement component integrated above the X-direction movement component;

[0068] The harvesting manipulator 7 integrated under the Y-direction moving assembly;

[0069] The harvesting manipulator 7 realizes rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com