Assembling and welding tool for gas turbine exhaust diffuser and assembling method for gas turbine exhaust diffuser

A welding tool and gas turbine technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of product deformation, difficult to guarantee assembly size, insufficient product rigidity, etc., to improve the molding quality, solve the lack of rigidity, and improve the appearance consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

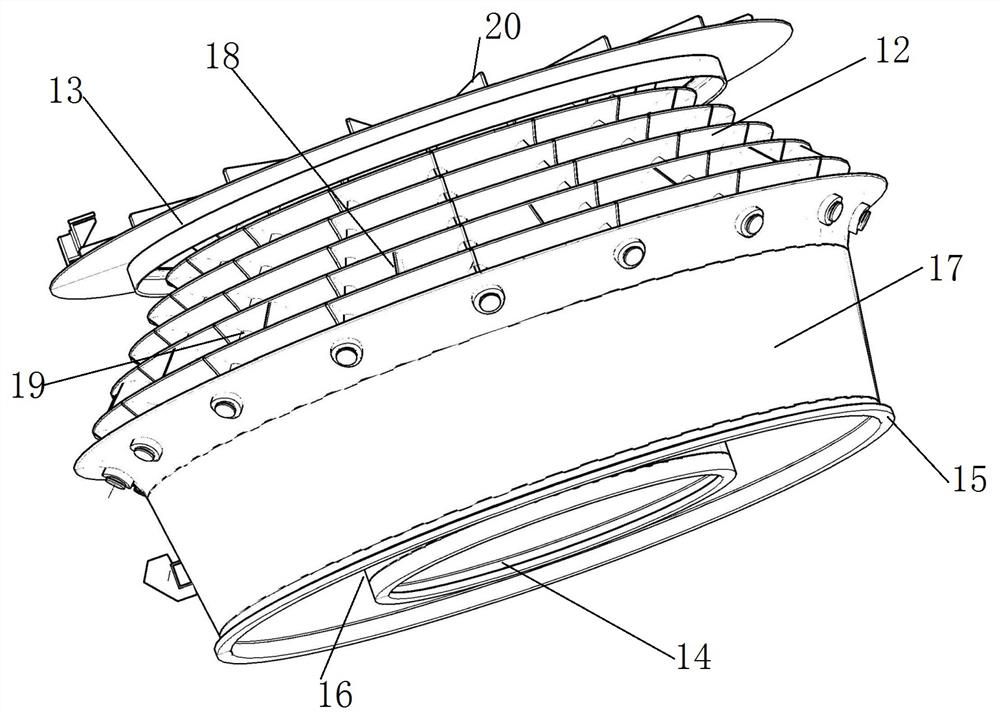

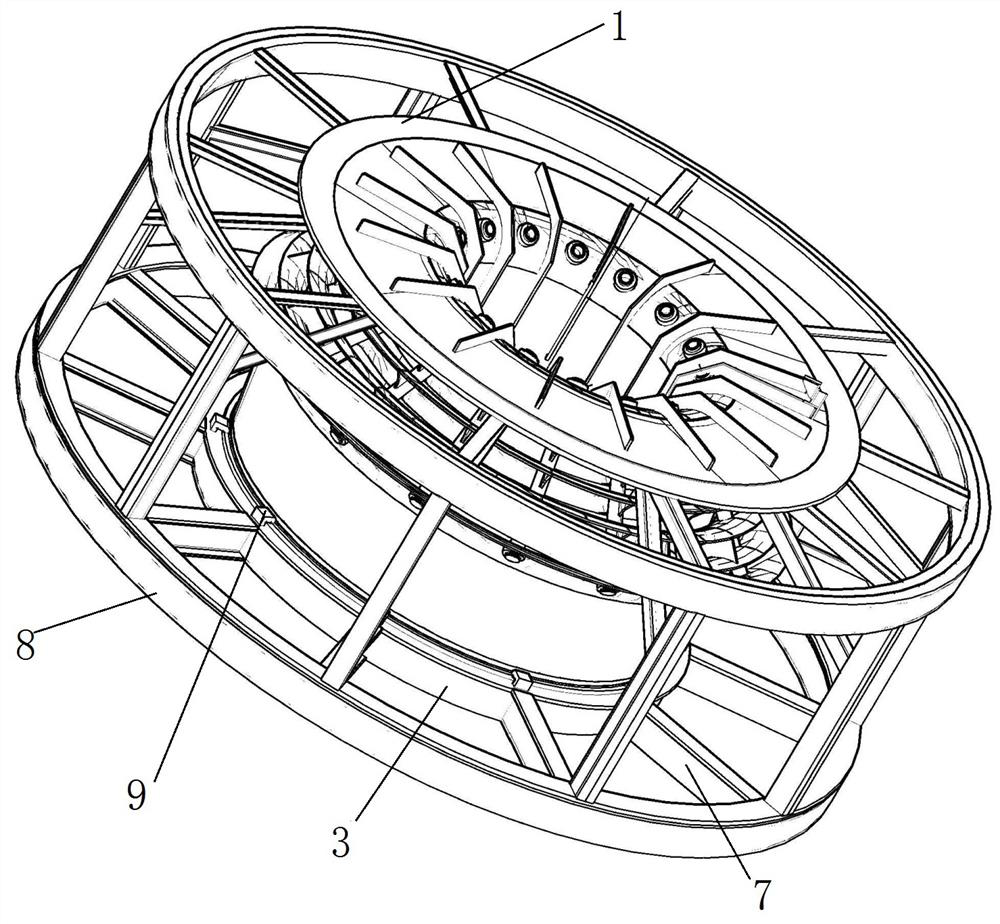

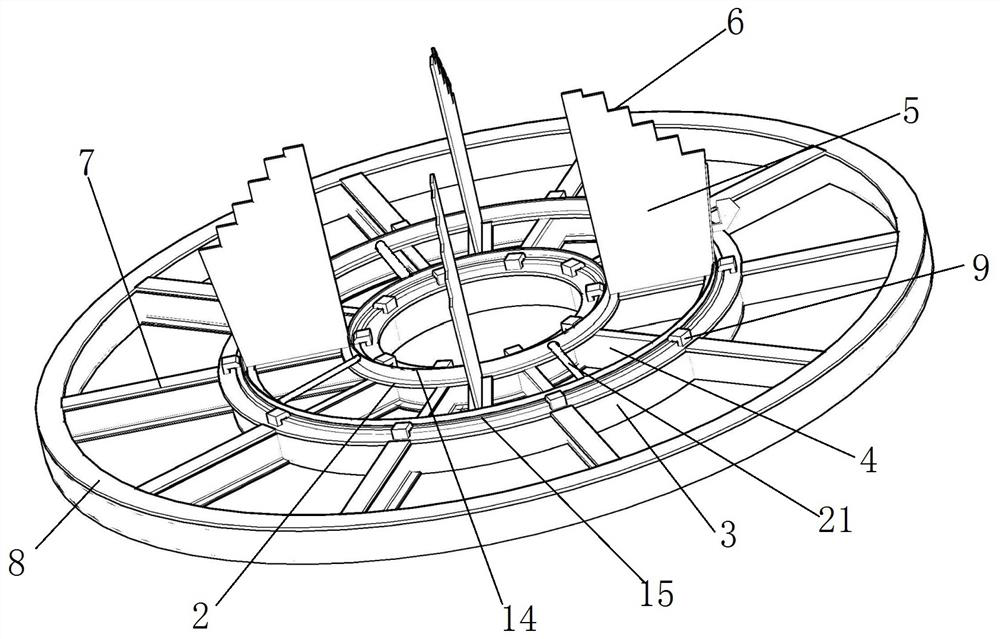

[0035] like Figure 2~9 As shown, a gas turbine exhaust diffuser assembly and welding tool, including a base device and a walking table bracket 1, the base device includes an inner cylinder placement ring 2 and an outer cylinder placement ring 3, an inner cylinder placement ring 2 and an outer cylinder placement ring 3 Connected by the connecting frame 4, several positioning partitions 5 are arranged between the inner cylinder placement ring 2 and the outer cylinder placement ring 3. In this embodiment, the number of positioning partitions 5 is four. The inclined surface is provided with several positioning mechanisms 6 for positioning the guide ring 12. In this embodiment, the positioning mechanism 6 is a plurality of positioning slots, and the guide ring 12 is layered in the positioning slots, and the outer cylinder places the ring 3 The connecting mechanism 7 is connected with the mounting seat 8, and the lower end of the walking platform support 1 is connected with the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com