Automatic detection system for air hole defects of laser tailor-welded blanks

A laser tailored welding and automatic detection technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of false alarm and missed detection of the head and tail of tailor-welded blanks, poor automatic detection ability, and poor detection accuracy. Achieve high automatic detection ability, avoid missed detection, and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

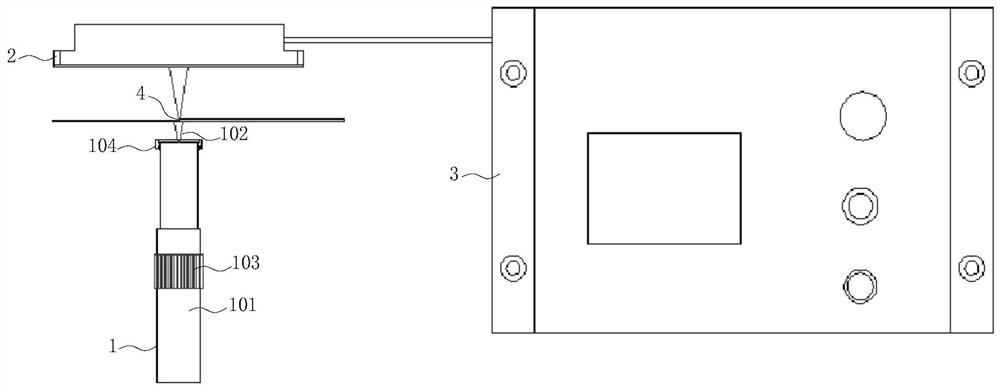

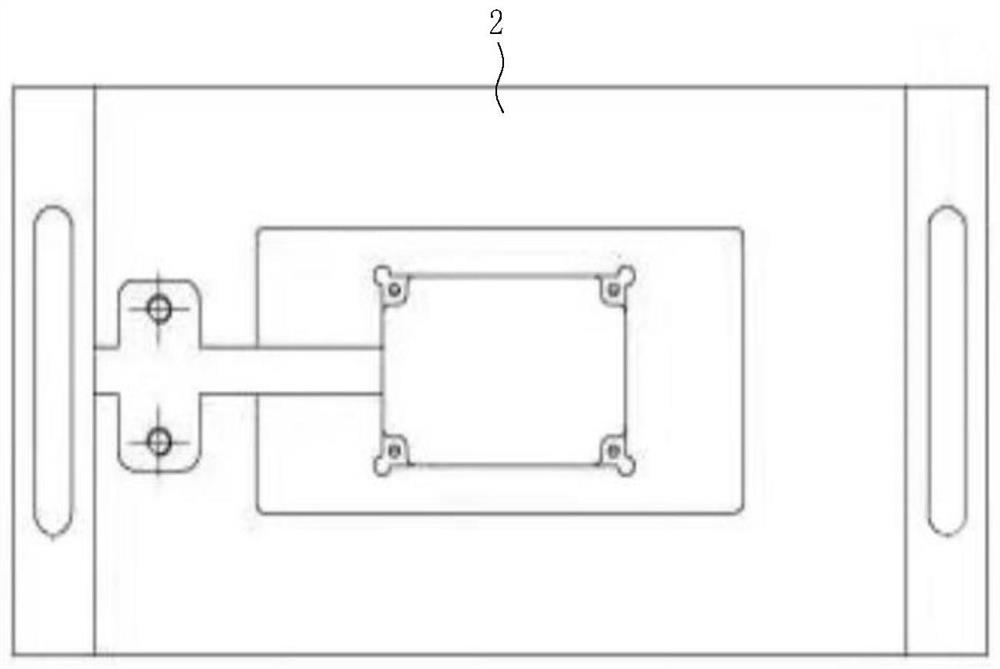

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] The definition of the pore detection system of the present invention: the pore detection system is an inspection instrument that utilizes the light-transmitting defect of the pore 4 hole of the laser tailor welding product, and adopts special wave frequency and high-intensity irradiation light to emit and receive and read the suction feedback signal. Effective inspection system for light-transmitting materials or machined parts.

[0038] The so-called laser tailor welding porosity 4 defects in the present invention are holes of different sizes that can appear on the surface of the weld during the welding process. In actual production, it is more common for the hole size of the pore 4 defective product to be around 0.1mm. The common characteristics of all porosity 4 defects in the laser welding process are: the holes are transparent, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com